Following my success earlier this week with undoing the bolts, tonight I went out and had another go at removing the ARB.

My main concern was the tension on the ARB - it wasn’t obvious to me whether the bar was under tension with the wheels on the floor, or with the front off the ground and suspension at full extension, or somewhere in between. I decided that the bar wanted to be horizontal with where it locates through the lower suspension arm bushes, and that this roughly equated to the front lifted up, but not as far as to lift the tyres off the ground. I left the nuts on the threaded ends of the ARB and carefully undid the u-clamp bolts on the leading edge of the subframe cradle. I watched to see if the bolts undid and exposed the threads, or if the tension of the ARB was pushing the metal u-clamp off the subframe, luckily I had guessed about right and the bolts undid and u-clamps dropped off without the ARB smashing my teeth out.

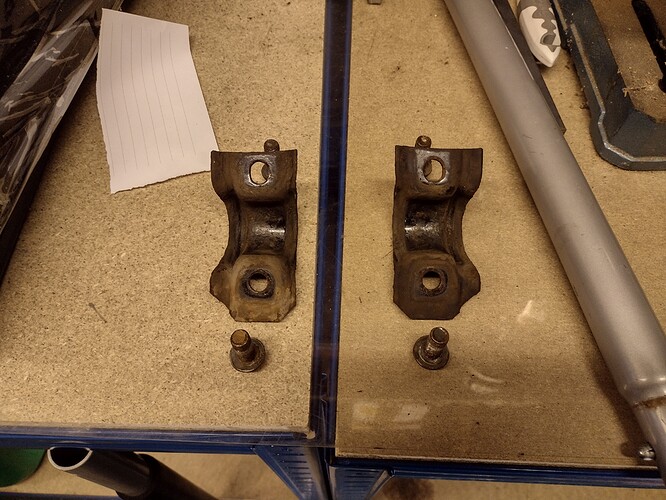

I dropped the u-clamps off and cleaned up the threads of the bolts with a wire brush and the bolts in a vice. They are ‘handed’ so I set them to one side for safe keeping.

I then lifted the car up, took both front wheels off and undid the nuts on the end of the threaded sections, took off the large washers and wiggled the rear top-hat bushes out. Then bashed the ends of the threaded section through the voids with a rubber mallet so I didn’t mushroom the ends.

I was then able to pull the ARB out from the front of the car, hooray!

As you can see its got quite a bit of surface rust on, so after unpeeling the split (intentionally) front bushes from the ARB I sanded it down, wiped the rust/dust off with a wet sponge and painted it with vactan, and left it propped up against the front wheel to dry

The bushes look to be original and are a bit crusty

These are the ones under the u-clamps on the leading part/straight bit of the ARB. I had to guess which u-clamp bushes to get as they come in 23mm inner diameter and 23.5mm, I went for the 23.5mm ones on the basis my car likely has a thicker ARB because its the SPROTS VERSHUN - a test with my calipers measured 23.37mm so with a lick of paint that will be 23.5mm I’m sure. I suspect the 23mm ones would have been fine in reality.

And these are the much crustier top-hat bushes that allow the ends of the ARB to locate through the lower arms - these were super easy to remove which bodes well for when I replace them with the PU ones that are on their way to me from Vladivostok right now.

The only ones I’ve not yet touched are the bushes that go on the inner end of the lower suspension arm because they look like they’ll be a right old war to remove from where they sit, and I really need a balljoint separator to get the lower arm off the car entirely to remove the old ones and replace with the new ones on order. I might look at this tomorrow night if I fancy it, or leave until its next MOT and ask the garage to do it with a press and whatnot.

I’ve left the ARB overnight for the vactan to dry properly and then paint it with aerosol black enamel this evening in prep for the bushes arriving hopefully next week.