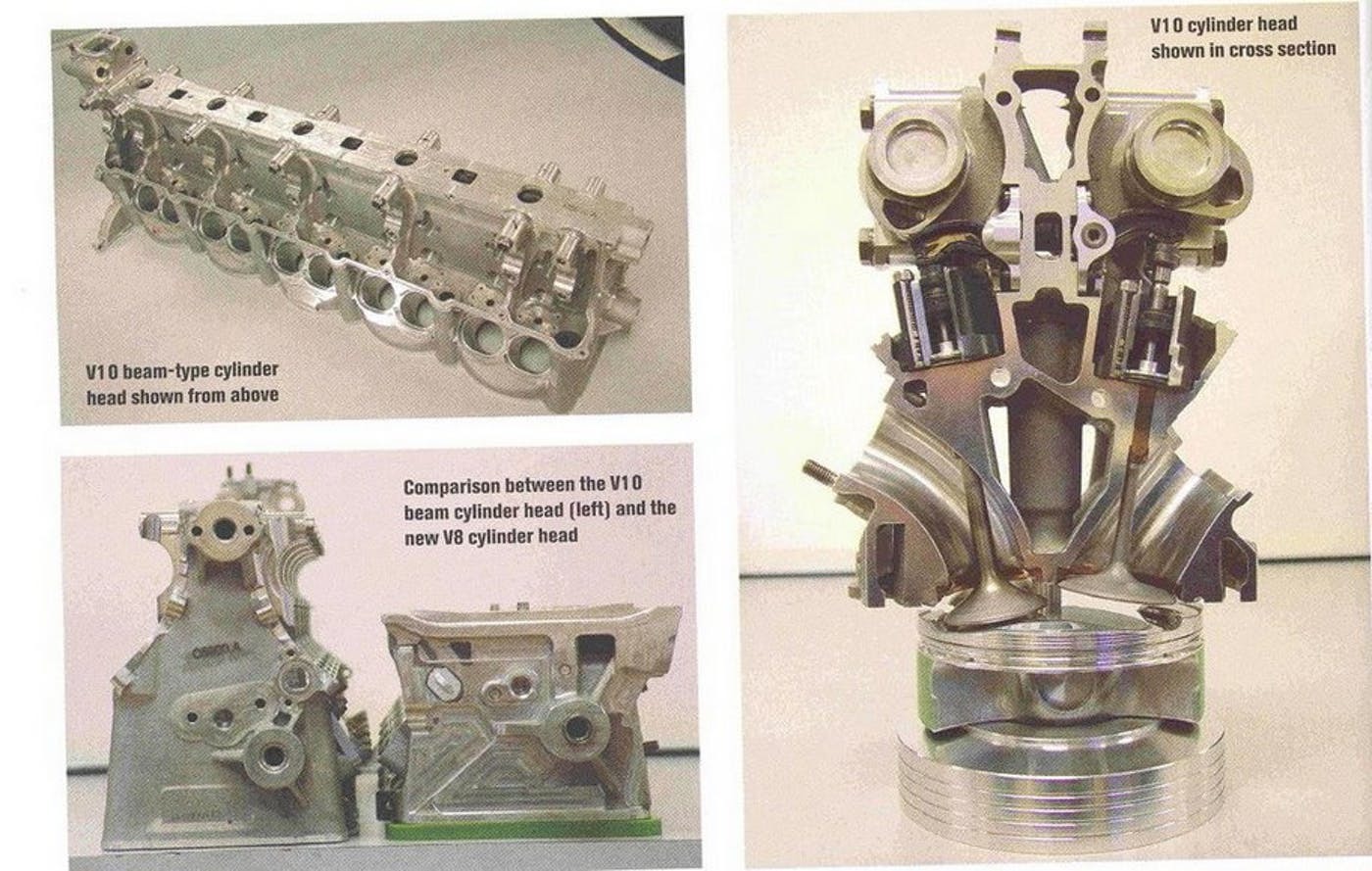

Thanks for that Mr Gormsby, I love the F1 pics - I think a Honda K-Series is probably the nearest thing we mere mortals could get our hands on, they are an amazing bit of NA kit.

I find it a bit sad that BMW and Honda have abandoned thier magnificent NA masterpeices for turbo setups. A turbo may deliver more power, but IMO will never sound as good as a ITB NA setup. I think the current V6 F1 turbo vacuum cleaners illustrate this point very well, with many missing the sound of the old NA V8s, V10s & V12s.

As for my car, I was never going make a F1 motor out of my H-Series, but I like to read & research what works and see what I can apply to what I have.

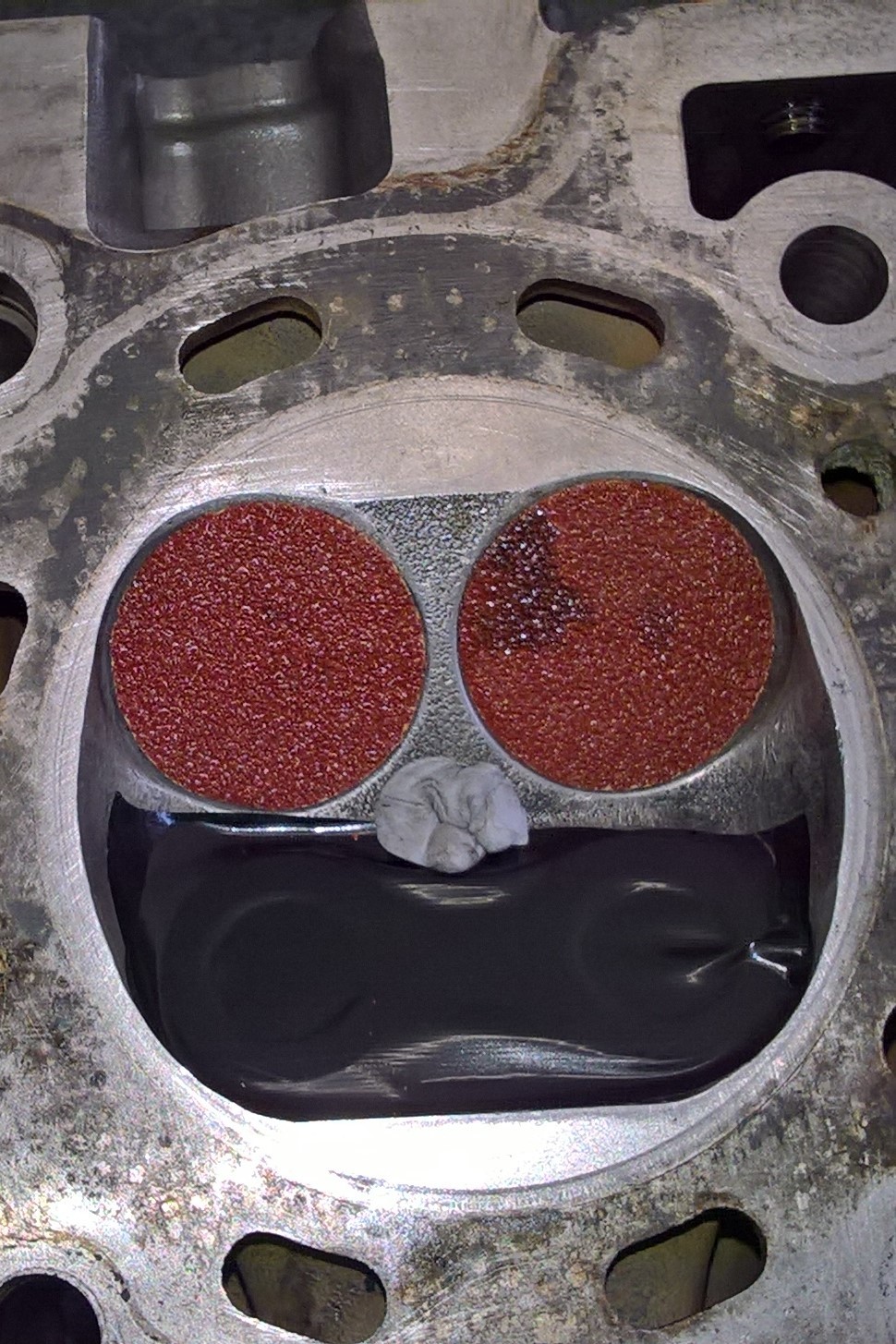

Most people when they build a high comp 1.6 use 1.3 pistons to get a CR of around 11:1. A CR of 11:1 was what my goal was too. However I knew there was some wasted potential, as simply putting in taller 1.3 domes does nothing to improve the squish, which on the stock H-Series is around 1.5mm.

So I did it the hard way, kept the stock flat top 1.6 pistons, skimmed 0.4mm off my block, and 1.5mm off my head. This leaves nice small combustion chambers (35cc), a squish of 1mm.

With my regrind camshaft though, this also left me with valves that “just” interfered with the pistons. While it turned over fine, as soon as it started a strange metallic melody emanated from the intake manifold.

Clay revealed that I only had 1mm of clearance, most of what I read suggested 2mm was needed. So I ended up doing some backyard flycutting of my pistons to get the required 2mm of clearance, this was from a method I borrowed from an online V8 article.

I had to open these up a bit more with a die grinder (I used a template to maintain the same shape on all pistons) to get the required 2mm axial and radial clearance.

Fortunately it all worked, and the car runs really well, alot of work though. Between the squish, high CR and ignition upgrades, if I take it easy I can still get the same fuel consumption as when I had the stock 1.3 - which suggests I got something right.

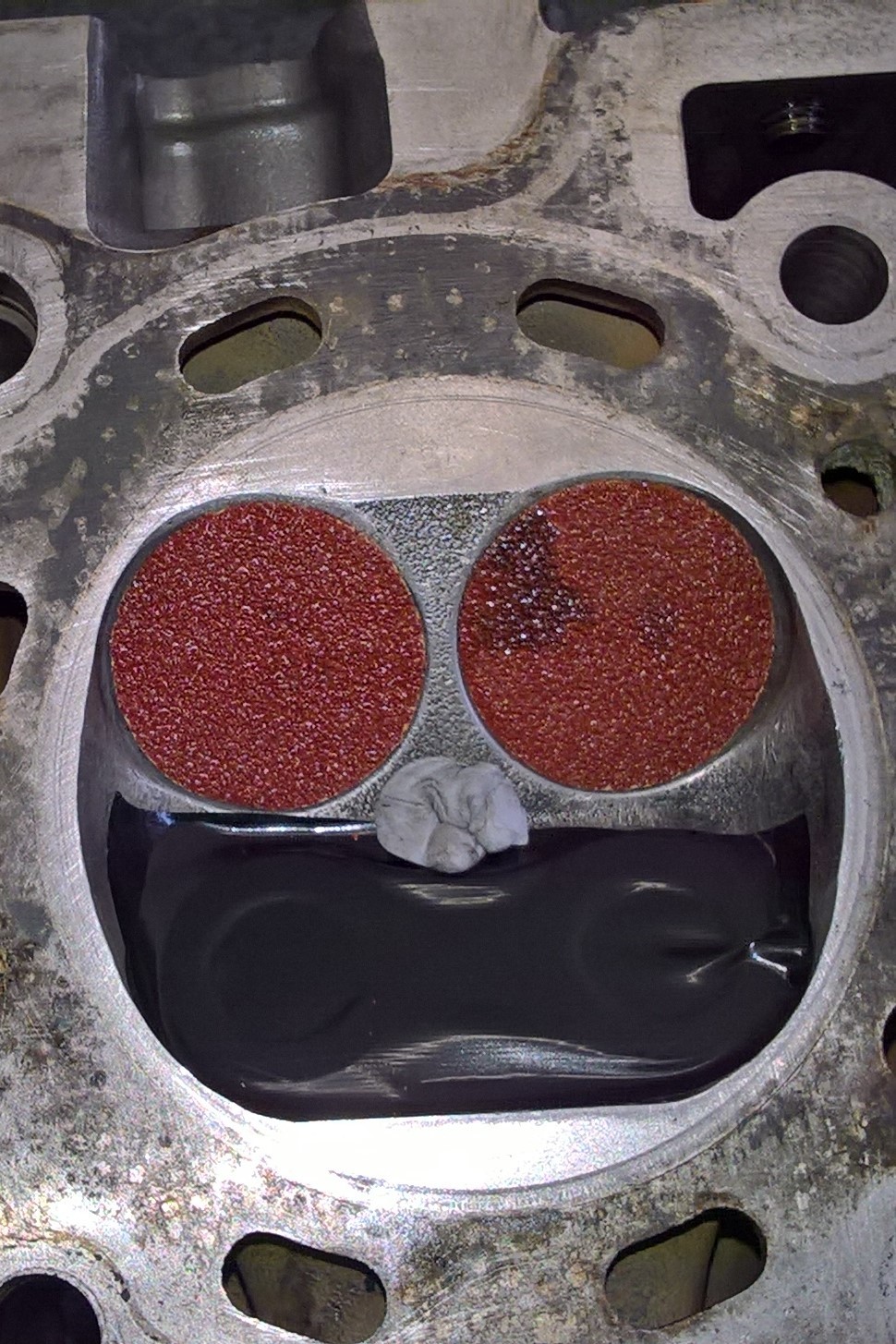

Here is Mazda’s take on it with “squish” nearly everywhere and a deliberate small pocket in the center of the piston.

Here is Mazda’s take on it with “squish” nearly everywhere and a deliberate small pocket in the center of the piston.

Rebuilt by a gearbox specialist with new bearings, seals, and with 1st, 2nd, 3rd, 4th, and final drive from a Gtti.

Rebuilt by a gearbox specialist with new bearings, seals, and with 1st, 2nd, 3rd, 4th, and final drive from a Gtti.