Everything going in is M100, except LCAs, I nabbed a set of L700 ones.

arrrgh that makes more sense then. I have used L7 and copen before and the positive camber was fixed by camber bolts as I said above. However I did use the L6/2 gearbox and with that the stock copen, and L700 ones were fine as the gearbox sits over the driverside more where the L7/sisiron style sits more to the passenger side. ( I use L7 lca’s also).

When I did 4x11.43 on an L200 I used an L2b2 gearbox and everything did stick out further and gave the car a wider front track but I was able to use swift (mk1) lca’s/hubs, brakes etc and I used Daewoo matiz front struts as they have a lower spring seat. and bolt straight in.

Progress update:

After triple-measuring, 80mm got sliced out of the middle of the short shaft, 100mm sliced out of the long one… That’s the Sirion shafts, keeping the Copen ones untouched… who knows, might find a copen with a bent axle or something?

Made a rough but ready plate to attach the Sirion shifter to.

We flipped the locator shaft (don’t know if there’s a proper name for it) and shortened the linkage 40mm to retain the original shifter position.

The linkage wants to intersect the cross-member…

…so I took a 30mm tube, and messed with it until it resembled a 40mm notch.

Once the drive shafts are welded, and final fitment confirmed, I can pull it all back apart, finish rebuilding the engine, notch the subframe, paint, and put it back together… then the only thing left to do is plumbing and wiring!

Damn I hate wiring ![]()

Progress report!

Notched subframe for shifter linkage clearance. Not my best welds, but satisfactory.

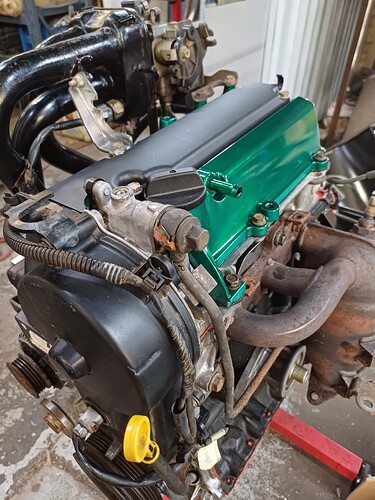

Engine pretty much done…

…except for the fuel rail…

Dang that returnless system.

Ordered a fuel pressure reg, and roughly knocked up a plate to bolt it to… waiting for the regulator to arrive before I tig it on to the end of the rail.

The lathe had fun pretending to be a mill, and went a long way to convincing wife that a milling machine is a great Christmas present. ![]()

Also ended up remaking the clutch cable with some new marine grade stainless wire. First cable i’ve done, and feeling simultaneously confident it’ll work, and paranoid it’ll fail. Oh the joys of modding. ![]()

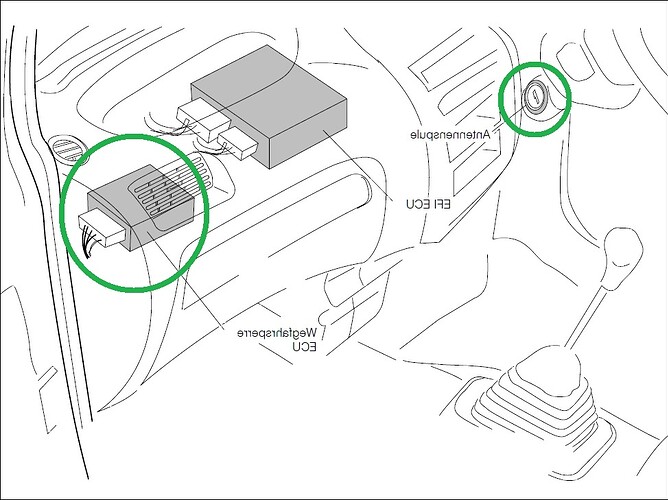

Had a look at the wiring, and realised I’ve got immobiliser issues… I forget who posted the wiring diagrams for that, but whoever it was is a legend!

Only thing that’s bugging me is what to do with the keys. Time to scroll the forums! My initial thought is cut and weld, but if there’s a more civilised option, I’ll hope to find it.

For the returnless design of the rail, you can just t piece the fuel pressure regulator so it returns to the fuel and still delivers the right 41 psi to the rail. Takes a heap less time than drilling / tapping the rail to fit a return line.

I’ll have to grab a photo when I’m near my Mira next. awesome move! always keen for a progress update

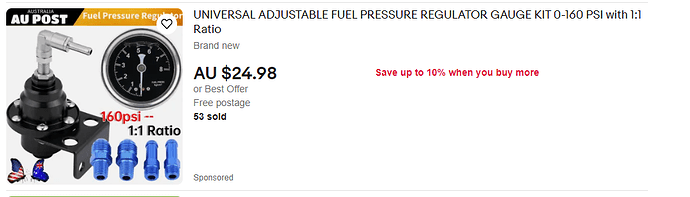

Yeah, I looked at that initially, but in the end it came down to price.

Cheapest in-line reg i could find was $150, whereas the factory style one I went with was on clearance, and cost $23 delivered.

I’ll have to check out your posts and take a gander at the Mira. Truth be told, I wanted another Mira, but the Move popped up for sale first, and I couldn’t resist.

[quote=“heckinwild, post:24, topic:6329”]…I’ve got immobiliser issues… I forget who posted the wiring diagrams for that…[/quote]I posted it either here or at a foreign-language forum. To be on the safe side, I’ll go back and copy it for later edit.

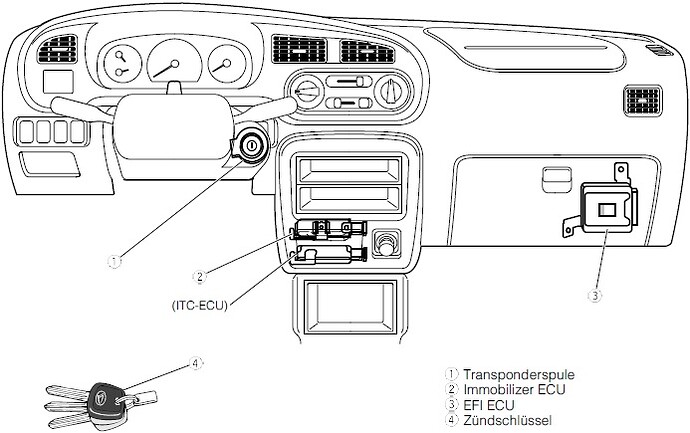

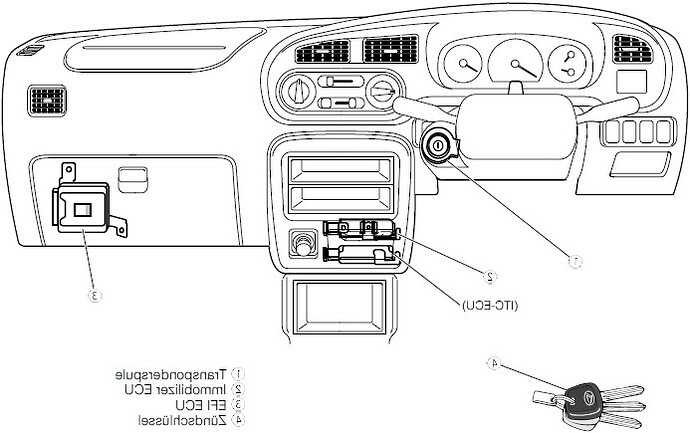

Simulating a right-hand drive vehicle, I had to mirror the device location image in reverse:

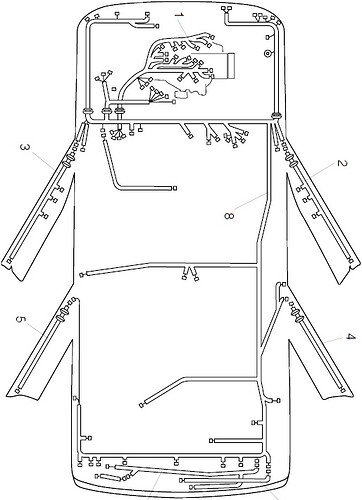

Your board computer will be rendered useless, in any case, while converting over to the EJ’s system. Therefore, transplanting the entire front half’s harness will be inevitable. Might as well replace the entire harness, given that connecting bulbs and electric-assisted window lifts (hopefully, not applicable, given that they needlessly add horsepower-robbing weight).

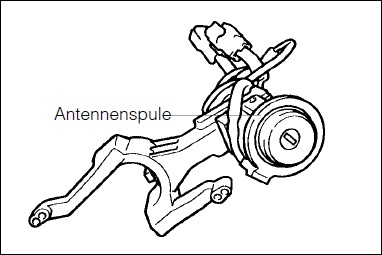

The antenna unit itself:

If you plan on keeping your replacement harness intact, this is where you’ll need to relocate the following devices. This image was taken from 701 data. 901 harnesses should be identical:

This may be more accurate?:

Progress update:

Been head down, camera phone down too… so not much in the way of pics to share, but lots of progress!!!

As in, almost all of it!

Biggest personal achievement is… the wiring is done! Now, please note, I said “done” not “correct”… won’t know that until fuel pressure reg arrives, but I’m quitely confident it ‘might’ be correct.

Buttoned up all the little fiddly bits, did some more mods to get the shifter in just the right spot, interior and front end back together, cut down radiator hoses and clippy bits on the fan shroud to make it all fit… had a mild panic at the exhaust trying to occupy the same space as the shifter linkages, but a little cutty-cutty, weldy-weldy later, and they were all playing together nicely.

All that is left to do are springs, since the taller Sirion hubs give the Move the Overlander treatment, bleed the brakes, little tickle to the wheel alignment, and fill radiator… and that’s it, other than the aforementioned fuel pressure reg… and she’s done!

Not a bad way to spend a couple of weeks.

The factory immobiliser is installed too… I noticed the cut of the Move key fit entirely inside the edges of the Sirion transponder key… so after taking them both to a key cutter, I was informed “Sorry, it’s impossible”…

Okay, fine, try another locksmith…"It can’t be done. "

Jeebus, okay… back home, and 30 mins later, with a small file, and the transponder key fits, and turns smooth. ![]()

Just a reminder that the opinions of experts can often be disregarded by crazy people with god-like abilities to figure things out. (I see you all here, doin’ what you do)

[quote=“heckinwild, post:29, topic:6329”]

…“Sorry, it’s impossible”…

…"It can’t be done. "[/quote]

It seems, this attitude has become contageous. If these so-called “locksmiths” continue doing business this way, they should’nt wonder, once they begin filing for bankruptcey.

Sometimes, such claims result from pure greed. An acquaintance of mine brought her 901 to a repair shop, after her upper Lambda Sonde popped out of its manifold. They told her that she would need a new manifold. I then ordered a tap set inclusive of inserts of which every shop should have available in the 21st Century.

That image you posted appears frightening, insofar that absolutely no clearance is to be seen between the frame and timing belt cover. If not an illusion, does one have to prepare for replacing a timing belt with the engine without the vehicle or must one simply disconnect each of the three drivetrain mounts, in order to gain clearance through moving the drivetrain away from the frame?

It’s both a little bit of an illusion, and also quite close.

I hope not to have to change the timing belt for a while, but when that time comes, it’s so easy to slide the subframe, and everything attached to it, to one side, I’ll probably just do it that way.

experts often say things can’t be done because they’re afraid people will come crying back to them because something doesn’t work or stopped working.

So, I am officially at my wits end.

Everything is together, engine is stock as a rock, with the exception of a fuel pressure reg set to 41psi… and somehow the engine is massively overfuelling, and I have been, as yet, unable to figure out why.

There are zero mods, other than it being in a Move now, and the engine ran, albeit a bit smokely, before I stripped her down for the clean and freshen up.

I’ve gone over all the mechanical and plumbing things, which are the bits I’m comfortable and confident with, so it seems to be electrical…

She’ll give a single kick on ignition, and then drown… if I then remove the fuel pump relay, and try again, she’ll wind over a few times before starting and running until the fuel is gone, but almost immediately (within a second or two) die if I re-insert the relay…

So, the question I have is, what in the electrical wizardry department would make the ECU pulse injectors long enough to drown the engine?

I have checked the water temp, air temp, knock and MAP sensors, all are present, accounted for, and plugged in, and I even went out of my comfort zone to check the injectors are able to pulse, and the ECU is sending a pulsing signal, the but beyond that, we get into electronics, which is a new world, in which I am a foreigner…

Any tips or suggestions will be gratefully received.

I should mention I did try winding down the pressure reg to a point it’d start and run, but any press on the accelerator was slow to respond, and when she did get up in revs, engine temps rose way too fast for me not to conclude she was running lean at those rpms… so I stopped doing that, and put it back to 41…

Is the fuel return line hooked up to the fuel pressure reg or are you trying without a return line? Is the 02 sensor plugged in?

FPR is hooked up to return line, and hooked up correctly. I tried two different styles too, a factory style and an adjustable…

O2 sensor, and all other sensors, plugged in. Labelled all wires before it was stripped, so I’m 100% on all plugs in, correct, and accounted for, and receiving power… that’s the one other thing I know how to check, for the sensors that receive it.

As far as testing if sensors are working… that’s outside my knowledge base.

Usually, it’s something simple that goes wrong.

Unlike the ED’s simpler engine management system, the one you now have is sensitive to even the most minor of abberations. I once had a 2000 Mondeo with a similar engine management system act like yours is now doing. Being unfamiliar with it, I looked everywhere except where it was difficult to find with the naked eye. It turned out that a weasel nibbled on one of the spark plug wires. This minute increase in electrical resistance sent confusing messages to the bord computer, to the point where the engine was billowing black smoke. This lesson cost my ex nearly 300€, because the shop didn’t just replace that one wire. They went ahead and changed the oil, the spark plugs, the other 3 perfectly good wires, among other unrequested unnecessaries.

In other words, I’d examine the ignition, before looking elsewhere. You might have cracked one of the coils, while installing your EJ, for example

I am pretty stumped tbh. So please excuse any stupid question’s. When you turn the car to start do you hear the fuel pump prime and then turn off before you start it? That is probably of no relevance but??? Do you have a different map sensor you can plug in to eliminate that? The one from your other engine wont work If it is from and efel or an ed.

Is this a vaccum leak? or has it been hooked up or blocked etc

Since I have the two EJ-DEs, both of which were running, but low on rings, I’ve been able to swap in and out map sensor and injectors and ecus etc.

That bit in the pic is now connected to the reference thingy on the fuel pressure reg.

Fuel pump primes and stops like she should.

She’s getting fuel and spark, at the right times, just the fuel is coming in very very wrong volumes.

yeh without seeing etc this one has me stumped. If I think of something I will surely sing out.