Hi! I was wondering if anyone has experience with swapping a manual gearbox to a stick shift in a L7.

I have a L7 with engine problems and rust but with smooth shifting and other parts.

I saw a mint 60.xxx KM L7 with an automatic for sale and started wondering if a gearbox swap is possible.

Does anyone have experience with something like this? Is it too much of a hassle or worth the effort? I have some experience and the possibility to rent a lift. But i’m also wondering what a Mechanic might ask for a job like this?

Thanks in advance

Cheers

1 Like

The only experience I have is with changing the clutch. People do it with the yrv turbo so I think it should be possible . Although I don’t know if the driveshafts are the same but if you have both cars you should be able to switch everything over.

Getting the gearbox off isn’t too big of a deal. Just remember to take the axle nuts off before lifting the car

1 Like

Daihatsu is pretty good at keeping dimensions standardized. Therefore, the axle shafts should be identical, unless one vehicle lacks ABS while the other has it. In which case, the length of all four will not differentiate from one another.

An inputshaft bearing for the crankshaft will be required. It may be possible to remove it from the damaged engine, if the correct tool intended for extracting it is used.

Do you mean renting a device to lift the vehicle or do you mean renting a lifting possibility in a rental garage?

I’m interested in buying your automatic transaxle including shift mechanism, if you don’t intend on keeping it and if the transmission isn’t defective. Have you decided yet, as what you wish to do with it?

1 Like

Never heard of the imputshaft for the crankshaft, do you have more info on that? It’s good to know since i might be going to convert a trevis (mira Gino) to auto if whe can’t find a good one for sale

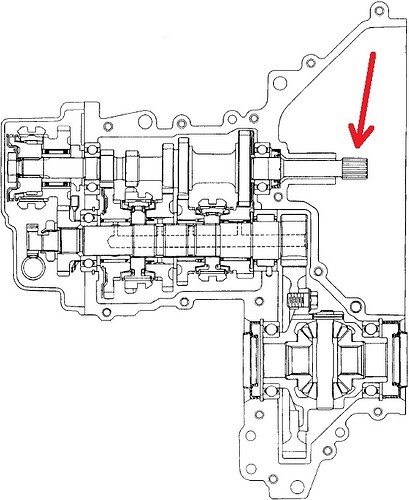

That’s the shaft protruding from the transaxle assembly of which the clutch disk is mounted to. As the transaxle gets connected to the engine, this shaft is inserted into the rear of the crankshaft for support. The following image shows a crossection of the shaft from a previous generation production. This might not have been updated for the following generation.

What’s unusual here is that this shaft ends with a spline:

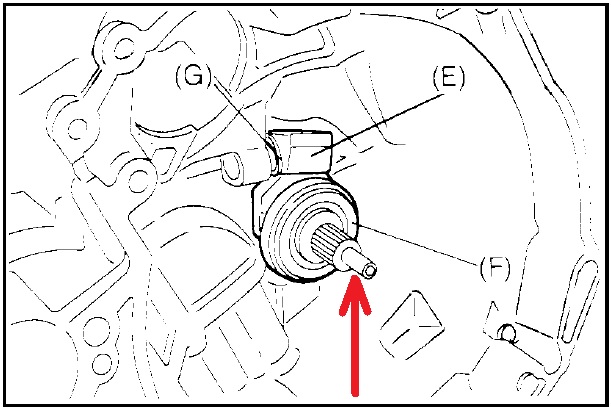

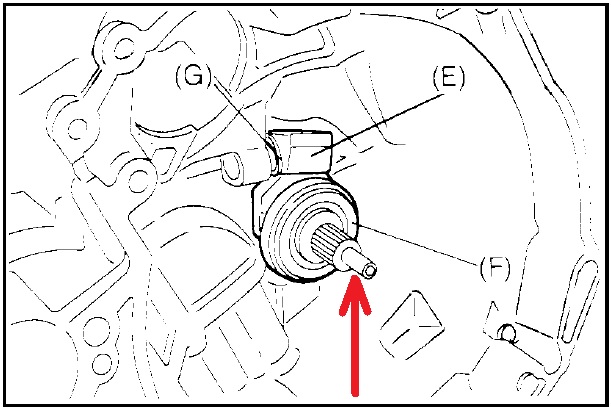

The second image shows the extension needed for keeping the assembly centered:

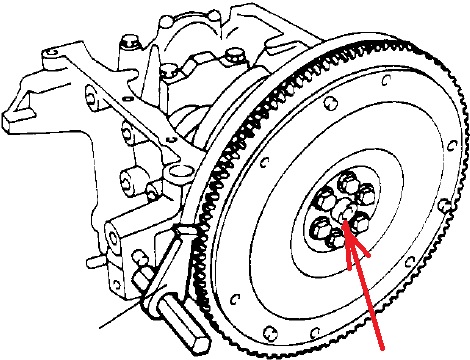

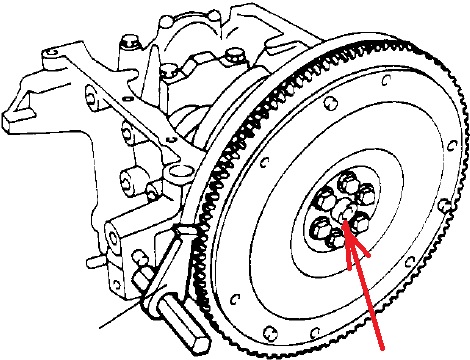

It is usual to have the bearing bushing pressed into the crankshaft’s end. However, it’s still possible to insert this pin into a bushingless crankshaft, while designing the transaxle’s input shaft to carry the bushing. The following image points out where these bushings are usually installed:

1 Like

Aha, to convert it from a automatic clutch to a manual clutch. Got it. Thnx allot!