2004 Sirion SL K3-VE2.

Long-running issue with oil getting burned - about 1L per 1000 miles.

The oil gets burned slowly if I run the car gently, but increases as the car is pushed. If I accelerate gently, even pushing the revs up to 6000, there isn’t a huge amount of smoke, but if I floor it, there is a definite haze of blue/grey smoke left behind me. It’s worse if I have been following someone and I have been holding the revs up to 3000- 4000 for a few seconds to make sure the power is there when I need it. Generally, on acceleration, it sometimes feels like the plugs are getting clogged during that period from idle to 1500 - there’s a bit of hesitation.

So, what have I tried so far…

I tried a different PCV valve - no difference.

I tried putting a little restriction on the hose going from the throttle body to the valve cover - the one that isn’t under vacuum and is in front of the throttle plate. I left the hose with the PCV valve in it alone. The idea was to slow the amount of air running through the crankcase, because it looked like a load of oil was getting sucked into the engine through the PCV valve. I thought reducing that air would help because the PCV would be sucking less of a volume of air and would therefore not be grabbing a load of oil droplets as the air was rushing out of the valve cover. It made a measurable difference to oil consumption and definitely slowed the amount of oil getting burned. But the problem is that there was now a noticeable vacuum in the crankcase. The car still smokes if floor it.

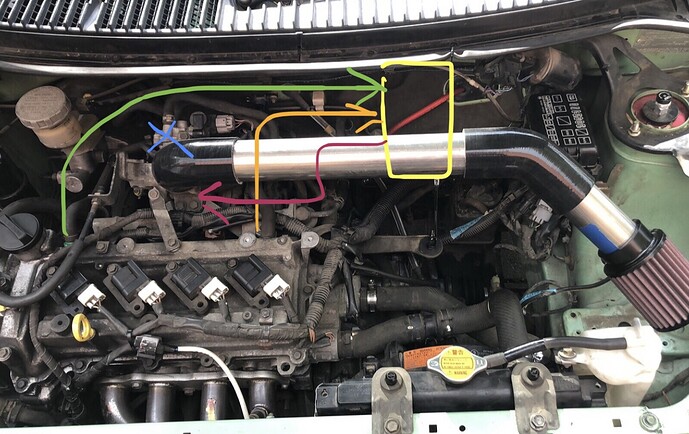

So I tried something else. PCV delete. Under FOT, any blow-by leaves the crankcase via both the PVC valve and the non-vacuum hose from before the throttle plate. I noticed that this tube is always dry, where the PCV end is always very wet from the oil getting sucked up. So, as a trial, I got a cheap PCV vale and gutted it, then routed the gutted PCV valve to the non-vacuum end of the throttle body to make it a simple vent, then I blocked the vacuum hose that used to go the PCV with a bolt, and added a one of those little air filters onto the hose that used to go to the throttle body before the throttle plate. Again, there’s an improvement - the car doesn’t hesitate from idle at all, and generally feels more responsive. But I can smell oil fumes - so that’s not great for the environment. It still smokes if I floor it. But it does prove, I think, that oil getting sucked into the engine is an issue.

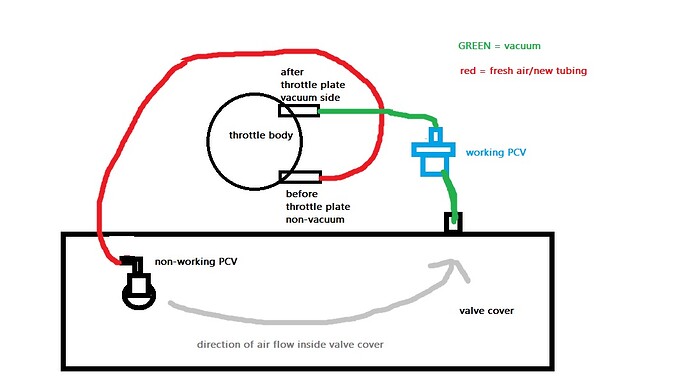

I’m onto attempt number four. I think some of the problem is the PCV sucking oil droplets from the valve cover. So I’m thinking of reversing the flow of the emission system. I want to put the vacuum tube with an inline PCV onto the other end of the valve cover (where it used to let the air into the crankcase) and have the non-vacuum end where the PCV used to be. I’m thinking this would put the PCV somewhere where big drops of oil can’t get sucked up, and it should close the system as it should be closed. Has anyone else done this? Can you see any possible drawbacks? I’m assuming that the lower air inlet into the valve cover just goes straight into the valve cover but lower down.

I’m going to assume the car will always smoke if I floor it. Now I am just looking at ways to reduce the amount of oil it uses when used more gently.