Thanks much guys. Do remember I value all your input and feedback. I’m still learning and would love to learn more.

So Cory/Taz (my fabricator) went crazy with my roll cage. The minimum requirement at the door area is a “X” He opted for a ladder bar anti intrusion design. Notice the pipe bends out at an angle into the door. With this design the driver can be more comfortable getting in and out the car and less likely to be making contact with the roll cage by just being seated.

During the cage build I started thinking about engine choices. Let me share here my thought process on choosing an engine.

-

Engine must be affordable and readily available.

-

Good affordable aftermarket amd spare parts support for engine and gearbox.

-

LSD must be easily attainable for gearbox

The options I had in mind were:

4age, 7age, B16, B18, K20/24, SR20vvl,4efte, D15/16.

First I was focusing on building a N.A. set up as the rules are more favourable for N.A where weight is concerned. Then I looked at what power each unit produced and how much I’d have to spend to get such power.

Now when I looked at what N.A people spent to get 20-30hp I was like…no no no, this is madness. I’m already used to a turbo charged set up and it can be reliable around track reliably

4age is my dream engine, I love the acoustics of it, however they are getting rare and are very expensive. Aftermarket support is limited and expensive.

B-series engines are available, but on the cost of the NA route I was not feeling it.

K20/24 is getting popular. Good aftermarket support. Goof power out from factory, but the cost price to locate the type R versions are high and the gearbox is not strong without going carbon internals. There is never a race meet in my region that a K-series box doesn’t get hurt at some time  . We were also concerned about how it would be mounted. Due to the design we might had end up with a really front heavy car just having to position that K to get clearances sorted.

. We were also concerned about how it would be mounted. Due to the design we might had end up with a really front heavy car just having to position that K to get clearances sorted.

Having chosen boost it was left to the 4Efte and the D15/16.

Now the 4efe is available and would just require a piston change. The prices were still a bit up there and could work with. A reliable engine and gearbox. Got hunting for a LSD and just missed out on one. So I went looking online. Prices were dazzling for whatever you could find.

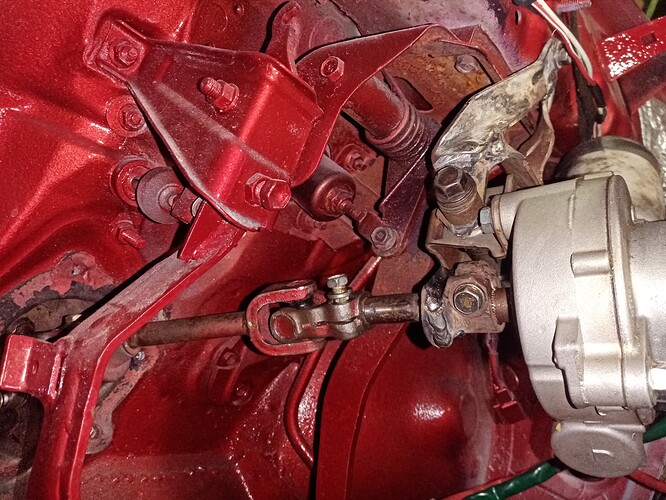

That left the D15/16, which had aftermarket parts around like snacks on supermarket shelves. Engine and gearbox readily available at good prices. From observation on reading they are also pretty reliable being turbo charged, just rods and vitara pistons and boost away. So I went for it.

BOOSTED SINGLE CAM TRACK CHARADE

. We were also concerned about how it would be mounted. Due to the design we might had end up with a really front heavy car just having to position that K to get clearances sorted.

. We were also concerned about how it would be mounted. Due to the design we might had end up with a really front heavy car just having to position that K to get clearances sorted.