So lets begin.

This is the long journey my car and my lived through. A car is never just a car for me.

This all started somewhere in 2015 in the Netherlands when i started my education as a mechanic. I was working 4 days a week at a Daihatsu/Mitsubishi/Mazda/Kia dealership and 1 day in school. My love for Japanese cars was there since i got interested in cars. My love for Daihatsu started when i was working. I liked the look of the little nuggets but they didn’t catch my interest much. A friend and colleague of mine said that these cars where just awesome, i didn’t believe him. This changed when i finally got my drivers license and the first customer car i had to test drive was a Daihatsu cuore (L701). I was in love. The raw mechanical feel, the noise and the brute sound of the 3 cylinder was awesome!

When i had my license i was very low on cash so i drove a moped for the time being. But i wanted a car, i wanted a Cuore. One day my moped broke down at work, i fixed it up but it was a temporary repair. I needed something else. Exactly on this day an old lady, long time customer, wanted to buy a new cuore. She owned a gray low km L701.

When she bought the new car, she sold the old car to the dealership and i bought it from my boss. Nicknamed by the old lady " Silver Bullet"

The name stuck.

This car was meant to teach me allot about welding, modifying, painting and to do things at minimal cost.

When i got the car i gave it a good wash and wax, nothing fancy. Cleaned the interior which was a mess after 16 years of smoking… Gave it a good service, plugs, filters, oil, timing belt and some new rust protection. Also repaired some rust spots near the wheel well. I drove the car a few weeks.

Then i saved up enough for lowering springs. They where the cheapest around and though it improved handling the ride was quite uncomfortable.

It looked so much better! To be able to adjust the camber i got some magic camber bolts. Also did a few wheel alignments to figure out what worked well.

Next up where wheels and tyres.

These 12"tyres where 12 years old at this point and had no grip at all.

I searched and searched and ended up with OEM 14" 6J BMW E30 wheels. The wheels looked like shit but they where 120eu, sold the tyres for 90eur since they would’nt fit. Painted the wheels and went on a hunt for some tyres. -old tyres–Gf for scale-

I lost a lot of pictures this time around since my phone broke grrrr (backups backups). Fitted some 165/55/R14 Khumo ecsta ps31. I was really happy with the new wheels. This really transformed the car. Only problem was the rear wheel arches, they were rubbing. I borrowed a wheel arch roller from a friend and heated the paint with my girlfriends hairdryer. This worked out great. No rubbing no cracked paint. To make sure it would never rust, i covered the folded in lip with seam sealer and paint. Of course i did another alignment at work.

The car was allot of fun but the 1L didn’t have the power i wanted. So like any other sane person weight reduction was in place. I never used the rear seats, only the trunk. So out went the seats, belts, lining and all the plastics. I kept the roof liner since its a pain in the butt to remove and its very light. Also since this car was still daily driven i kept everything from the front seats. This made a noticeable difference in sound and acceleration. Also the trunk is now much bigger! And I’ve found my old friend.

Nothing a little welding couldn’t fix!

The car was very fun to drive, very light and nimble.

But there was something missing, power. I’ve seen @Marty video about his engine swap on the L7 and i knew i could do it. I went searching for a damaged donor car. This seemed harder than i thought. Here you cant buy a whole car from the wreckers. Also no one sells there wrecked car. Buying all the parts i needed would be way to expensive. Also i was unsure what i needed. The search was put on low flame for some time, when oneday i got a notification on my phone, i got exited, looked and there it was the donor car for my L7.

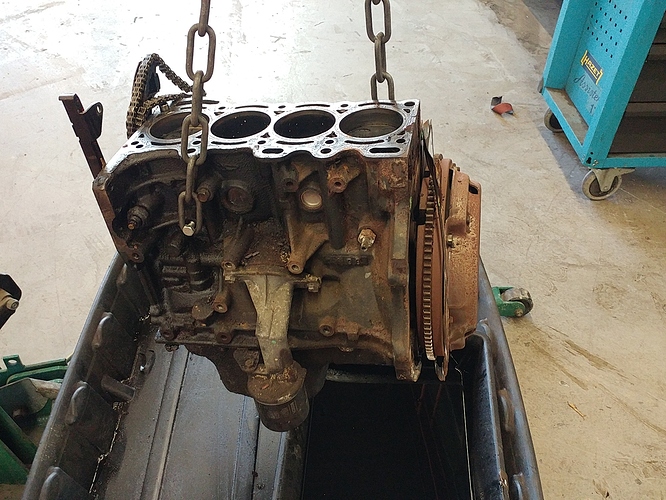

A gray gold ish Daihatsu Sirion M101s with the K3VE2 engine, 220.000 km on the clock, smelling of oil, sticky brakes, worn clutch and running on 3 cylinders.

Perfect.

I bought the car the day after for a very small price.

Now i needed to diagnose why it was running on 3 cylinders. I hoped for a busted coil or plug. This was not the case. Sh@t. Injectors? nope. Compression test revealed part of the problem. No compression in cylinder 3. Using an endoscopic camera i’ve found the problem.

Okay no problem this will just be a little bit more work. Its all good.

Now it was time for the fun part, pulling everything out and rebuilding the engine as best as i could.

I am still very thankful i did this on a hoist with pneumatic power tools, i have deep respect for you backyard mechanics!

I took out pretty much everything , full loom, seats, heater control panel, heater resistor, cluster, switches, fuse box, ecu’s, clock spring, exhaust, steering wheel and complete sub assembly. I forgot the master cylinder, i think its bigger, i’m not sure though.

Some time went by and i saved up some money to start the rebuild process.

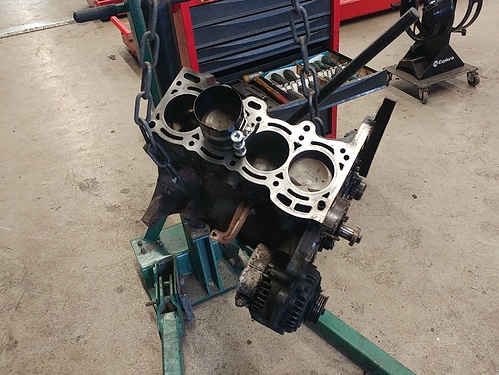

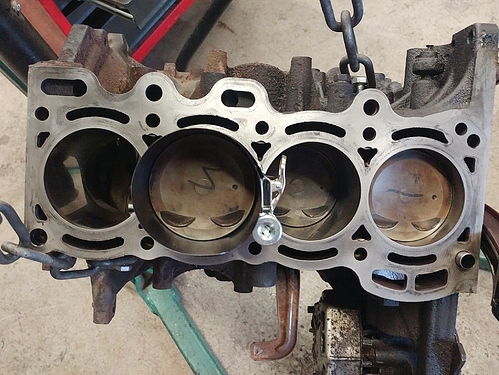

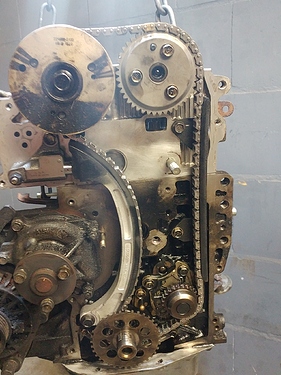

Pulled the engine apart piece by piece. The bearings where recently changed which was nice. But the head needed work, piston rings where easy to change now and also the chain. I measured everything up and the engine was in pretty good shape! No pics here since i did everything alone and needed to be done quick.

I did most of the head work myself at the living room table. Girlfriend was not amused.

The head was professionally cleaned and flattend. Also the valves that where ok are reground. New valve stem seals. I did some valve lapping, this was a very very tedious job. I had to order some valve buckets to get the valve clearances ok. Since the valve’s where reground the clearances got very tight, but there alright now. I have set them at the highest end of the spectrum since i didn’t want to do this part again. I used this cheap tool (-+15eu) to assemble the head again. Total pain in the butt but it worked.

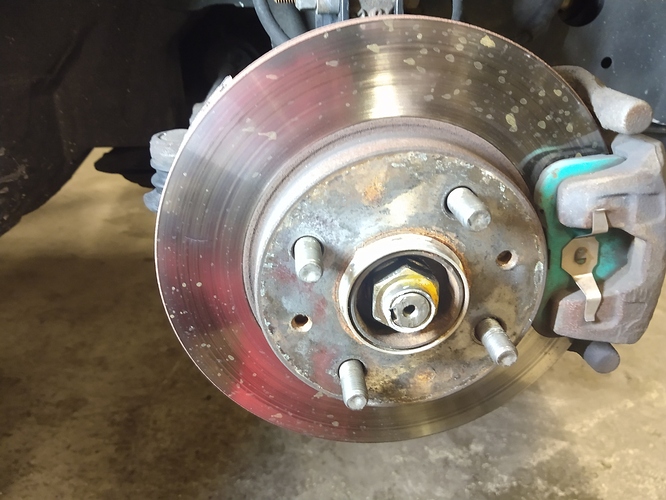

The brake pads and rotors from the L7 where almost gone so i figured id already fit the larger sirion brakes.

The pins and pistons where completely stuck. I rebuild the calipers. I should have painted them but money was tight and since this is not essential i left it for a later day. I also put in the sirion seats since these were much nicer.

New pins, new rubbers and they were ready to go.

For disks i went with normal Brembo disks and pads. These were tested at the Nuerburgring and failed…

After just 1 lap i got intents brake fade. So on the hunt for better pads and brake fluid.

I ended up with Project mu racing green pads, brembo disks and quality dot 4 brake fluid. I never had problems again.

Back to the engine.

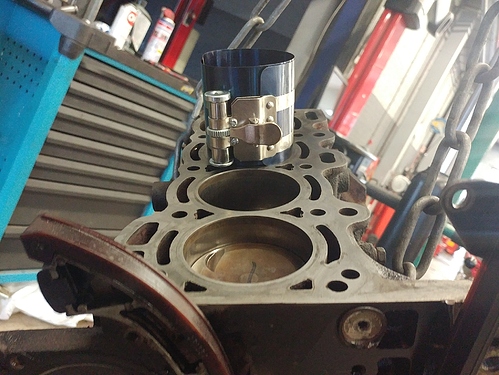

I got allot of parts in the mail and it was assembly time. New rings etc all went in pretty easy and without complications. This is a fairly easy engine to work on. No spacial tool required.

The next part was the k-frame. Cleaned all the oil off it and gave it some new antirust coating.

The LCA’s from the sirion are longer and if used they would add about 3 degrees of camber. This was a little too much for me so i bought new one’s from a L7. Drive shafts would be swapped over from the L7 as well as the steering rack. Next challenge was the sway bar. Later i found out a copen bar would fit but this worked just as well.

I used a torch to heat the metal up enough to make it slightly bendable. Then a large pipe was slid over the end and bend into shape. This took along time since the shape is rather important. In the end it all worked out! Some new paint and done!

Powersteering was a no go for me since there is allot less ‘feel’ in the steering. This meant removing the pump reservoir etc. Because i removed the pump the belt needed a tensioner and a different routing ofc.

Using the EJ-DE belt tensioner and some new bolts i was able to run the belt like this. Shedding some pullies thus weight in the process. Everything back assembled and ready to go in. The little blue wire is a signal wire for a oil temperature gauge.

Everything was ready to go and again i was able to use the hoist and power tools at work. I started by stripping the L7 the same way as the sirion. Dash, fenders, bumper everything off.

Then undid the wiring from the engine and behind the dash.

The car was ready for transplant. Put the k-frame on a pallet, undid the bolts and lifted the car away.

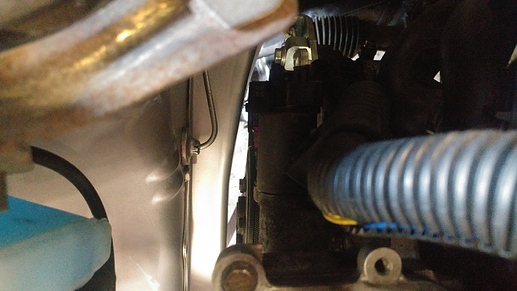

With the engine out i cleaned the bay up a bit and hammered out the bar on the right hand side to make some room for the alternator. In retrospect this was not enough its still rubbing in hard right corners. Stiffer engine mounts and some light touching with a big hammer should do it. Swapped over the steering rack and the shafts.

waaay to closeThe engine went in flawlessly. Same way i took it out. I hooked everything up. Coolant hoses etc. This was the point i wish i had labeled the connectors on the sirion loom. I thought the go in 1 place and one place only. This was of course not the case. In the end everything was hooked up an ready to go. Turn the key and it cranked and cranked but it didn’t fire up.

After 1.5 hours of diagnosing the problem I’ve found the problem. One plug for the igniter was not plugged in. Stupid me.

Cranked the car and Voila! Fired right up no problems at all.

After everything was put back together i took the car out for a spin. I was amazed by the amount of torque! It was really different. Didn’t really feel the power since the oil was still cold and the new rings needed to wear in.

Next up was an alignment of course. And thankfully the sway bar was bend straight! The alignment didn’t lie.

Now for the cluster, which worked perfectly, it looked like a fricking Christmas tree. Engine light was true (idle valve fault), the abs was on because of the missing rear sensors (don’t want abs anyway) hand brake indicator was also on (no clue why). I pulled the smd’s off the board for the abs and handbrake.

Now everything that needed to work worked, no more flashy lights. Except for the MIL ofc.

I drove the car for a bit and went for the hard brake in. Meaning you drive at varying rpm until engine oil i warm, then its time to floor it high in the rev range. This was very unusual to me but my +50 yo colleague who is into racing, swore by this method. To my surprise this worked really well. After 5000km first oil change. There was some slight grayish stuff in there. No problem at all since the second oil change at 10.000km was perfectly clean.

Also the compression test showed 12 bar.

I enjoyed the newly won power as much as i could. The car is very quick now. But its lacking allot in the corners. Also 1 shockabsorber was leaking a bit.

Time for change. Since this car was build for track and street use i wanted to invest in some proper suspension.

Bc coilovers where easy to get and installed perfectly.

(old vs new)

The drive was really nice, much more stable and much more comfortable. And with allot of help from @Mr_Gormsby i got the suspension dialed in pretty nicely. Alignment also dialed in, again. The car pulls through corners like a madman! An amazing transformation.

Some rust repairs followed. Im not the best welder but trust me this is solid. (the hole was also closed)

Now my girlfriend went on a drive with me and some friends. We took up the pace a bit on the deserted country roads and she experienced the speed and nimbleness of the car. She was getting worried that the car wasn’t safe anymore, and i agreed. Safety was the next step if i want to drive this car on track.

After some time i went ahead and bought 2 used sets of 6 point harnesses. The where in really good shape.

2 bucket seats. These where the cheapest FIA approved seats available.

Now it was time for cage. Since this was still my daily driver i didn’t want to go full cage. Since this is a safety device and i dont trust my welding that much i got it professionally done. 3 point belt still fit.

While welding he found some rust spots on the wheel arch. This needed fixing asap.

Some think 3 mm steel plate was used. Again not pretty but really strong. This was covered in seamsealer and paint.

For the seats i had to fabricate a mounting bracket that was welded in. No moving seat for me. (no pics here  )

)

For the belt anchoring i drilled holes in the floor and used some 4mm thick plate at the bottom of the car to secure the eyebolts. The shoulder straps went on the cage via a wraparound manner. 3point seatbelt went out.

Now this car got allot less comfortable and after a few weeks a community member had to get rid of his blue L7 for cheap so i bought it. F@ck my girlfriend will kill me.

Here she was the blue turd.

Now i had archived my dream, have an awesome project car and a daily driver. Really happy now.

Put in a new steering wheel to finish the look. Btw for the European guys, allot of the hub adapters fit the L7. Everything that fits the Lexus is200 or the Starlet will fit the L700!

Now for the ultimate test. A weekend at the Nuerburgring. 300 km drive to the track and 6 laps on track. First 2 for warmup and getting used to the car, 3 laps to have heaps of fun while chasing BMW’s,Gti’s and rental swifts.

Now my best friend is a really good driver, he knows the Nordschleife really well and wanted to have a go. I never sat in the passenger seat. Weird. And damn he was bloody quick! The did things i could have never imagined. Great weekend no problems apart from warped rotors.

Back home…

The rotors got waaaay to hot. I’ve got to find a solution to this and i have some idea’s >>

That’s it for now. Sorry guys it took so long. Ill keep you posted more frequently now.

See ya!

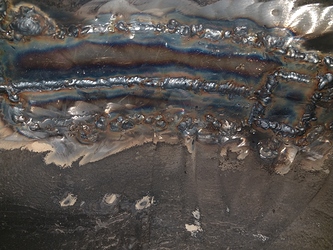

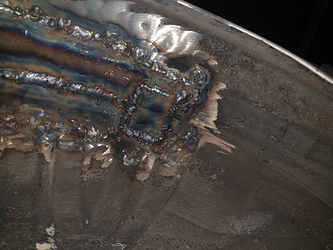

that is a crack isn’t it?

that is a crack isn’t it?

)

)