Attempting to keep mobile until the engine in my 601 is finished, I went out and bought the following, after seeing it on ebay. Initially, I spotted a gold-coloured one parked at a repair shop. It had an automatic gearbox of which I prefer for urban driving. But upon inquiring, the gearbox had problems. Therefore, I needed to wait until M.O.T. and gearbox were finished. In the mean time, I searched the usual online outlets, in order to determine an average price for these. After having found a bargain on an irresistable silver one, I simply went out and sealed the transaction

Here, a former owner stuck what looks to be FIAT Panda stickery. These will be the first embarassments to get removed:

For those who aren’t familiar with these, they dramatically differ from Daihatsu Keis, in terms of ride quality, handling and drivability.

The ride on these are comparably soft and the ground clearance comparably higher than that of especially the 601s. Both the 6 and 901s handle better and feel more precise on winding hilly roads. This is because of not only differing ground clearance and spring travel between both brands. The Daihatsu’s more expensive independent rear suspension set-up can only deliver better handling than that of the Suzuki’s solid axle. I would definitely, in this case, prefer the Daihatsus for longer distance driving, despite the more firm ride qualities of these.

The engine in this one displaces equally with those of the 901s. The difference being the amount of cylinders, the Suzuki running smoother. But, demonstrating shortcomings, lacking the usable low-end torque of the ED-20s and overall horsepower band of the DOHC Daihatsu 3s.

The Suzuki 4 is equipped with a maintenance-free timing chain, eliminating the need to worry about failing belt tensioner bearings near the end of belt replacement intervals.

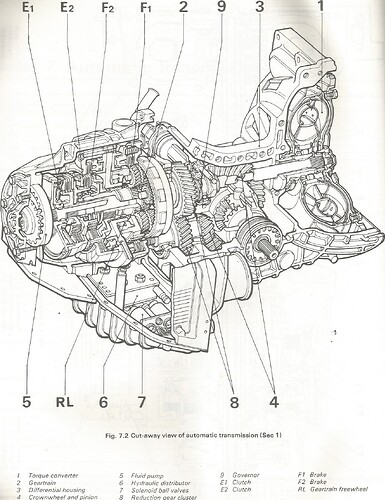

The gearbox is better suited for urban driving, given that the first 4 gears are more closely ratioed than those of the Daihatsu boxes. The fifth gear is wider spaced for exclusively freeway driving.

Aside from bumping out those dents, attention will be paid to the shifting mechanism of which feels dry while somewhat sloppy. It may just be a matter of replacing whatever rubber grommets and plastic bushings may be deteriorated.

If not welded on, I will remove the heavy trailer hitch and put it aside for emergency use.

I will also experiment with disconnecting the power steering assist, to see if roadway feedback can be improved.

The signal horn will also be replaced with separate high and low-toned examples, identical to those in my 601.

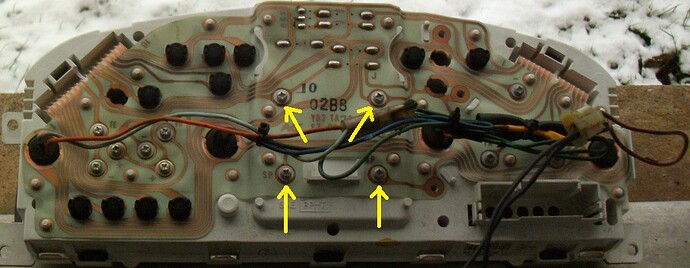

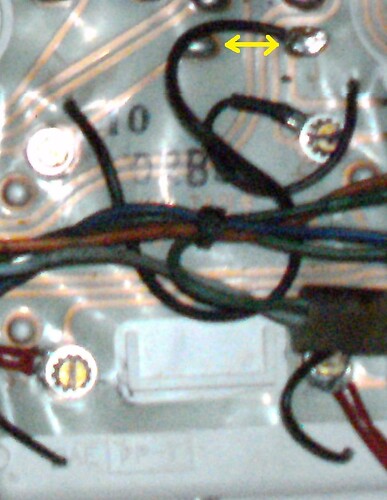

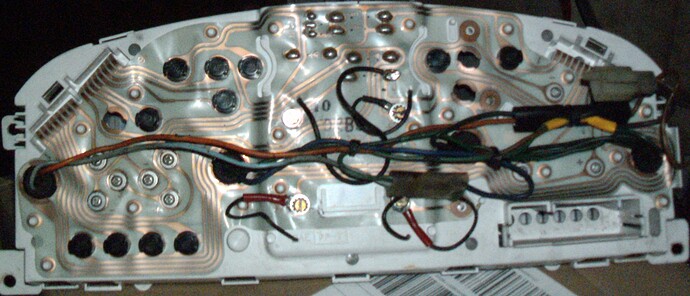

The difficult to see at night red tachometer and speedometer needles will be coloured yellow, in order to counter my red-green colour blindness. 30, 50 and 70 kmh markings will, as in my 601, be highlighted