Hello World!! … I live again …

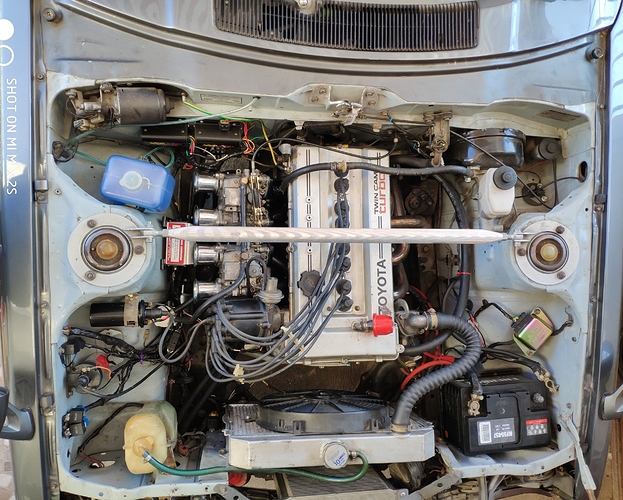

I must confess two things; first, that the last date I was unfaithful because the little sirion was not ready yet, so I participated with a toyota celica 1977 with atmospheric engine and solex carburetors (which make a really orgasmic sound)

Here some pics…

Second, I was scared to death that everything we had been preparing for the car not worked. At least until today, it’s working.

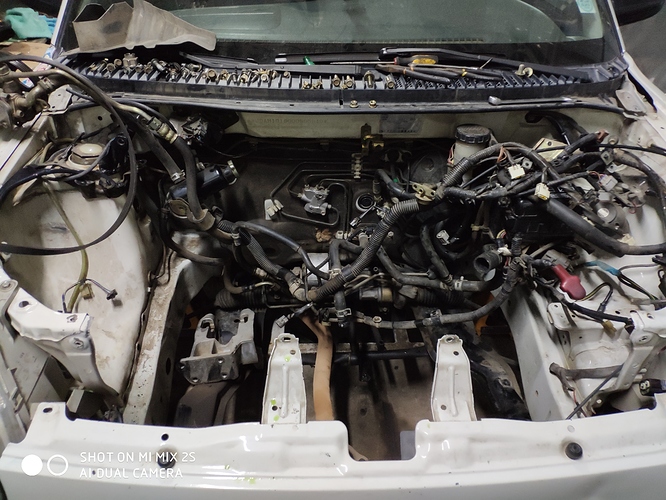

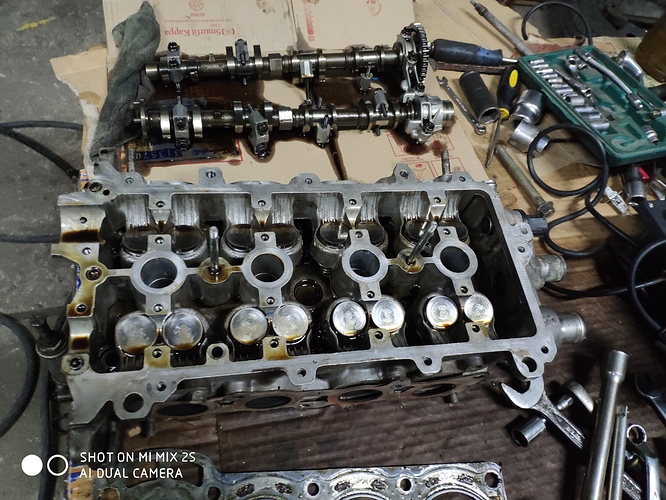

Well, I tell you a little bit. We disarmed the engine with a little fear, I had never participated so much in car racing, I didn’t know how the engine was going to come out, fortunately the engine came out in good condition, without much to do.

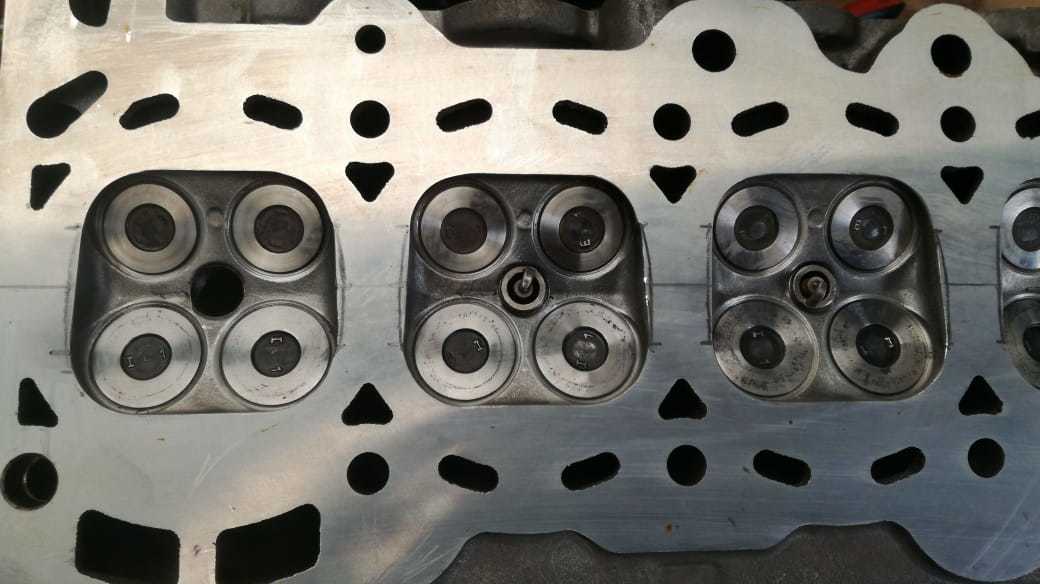

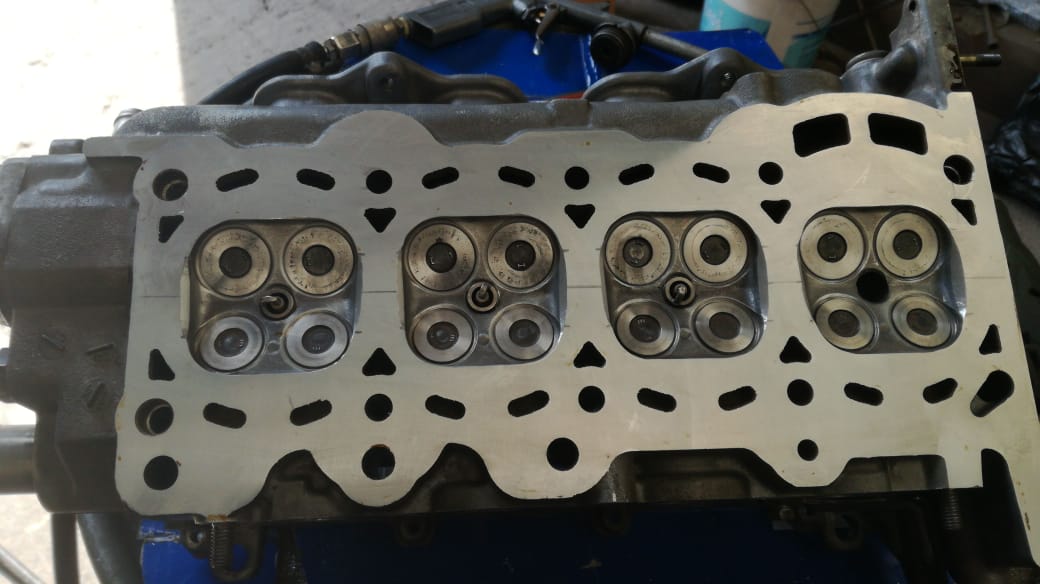

We send it to the rectifier for review and work. We take advantage of preparing the cilinder head a little.

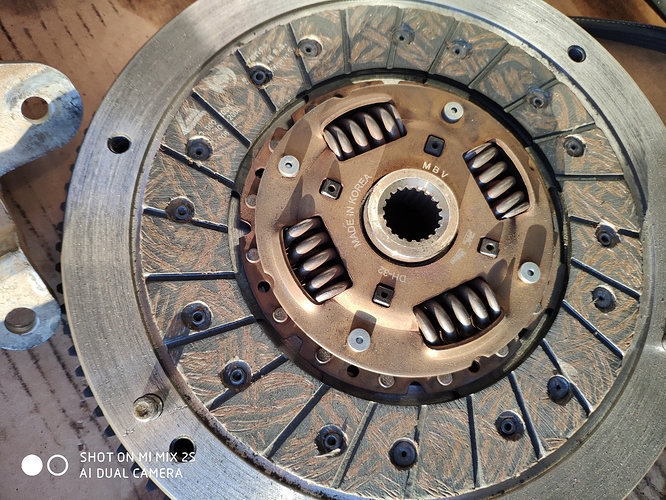

Taking advantage of that it was all disarmed we sent to make double clutch press (standard disc)

well, with everything in our hands we build the engine with a lot of faith, maybe too much …

The engine didn’t turn, it was as if it were hitting a valve … ok, we will have to disarm it again and see what happens.

I must have said a million expletives at that minute, I was really angry.

Once disarmed we realized that what was coming was the head of the piston with the head cilinder (another million expletives came out of my mouth).

After a while we decided to lower the cilinder head by the sides of the combustion chamber, according to our calculations we would solve the problem.

We were right, with that everything worked without problems. In theory the pistons were plug&play but for some reason, this was not the case. Fortunately, it was not a big disaster.

Before mounting the engine, we hardened the rear engine bracket and reworked shift lever bushings, then assembled the engine.

The installation of the header was much simpler … really plug&play (beautiful the header)

And the moment of truth arrived … it broke or it split …

The engine started at the first, soft, somewhat noisy …the rear support does not let the engine move transmitting vibrations to the interior.

The header began to change color, but it was beautiful … after the adjustments of a newly rebuilt engine we should go to a test.

the clutch … it was very very hard, uncoupled a little slower but coupled immediately, I think it’s something to get used to.

I did not want to accelerate it for fear that the VVT would crash the valves, little by little I was gaining confidence until I reached 7,500 rpm with success. I do not hear it detonate (maybe I have a bad ear), I’m using gas 97 RON, but I think for racing needs something better.

With half throttle is another car, much more torque. With the pedal fully open stays a bit, maybe detects detonation, maybe it lacks a larger acceleration body.

For now I’m still in the process of testing, but this month I have two races. One on October 13 and the next on October 21.

I still have things to do, but this is what I can tell you until now!

a hug!