I love the top mounts, where would one find a bearing like that?

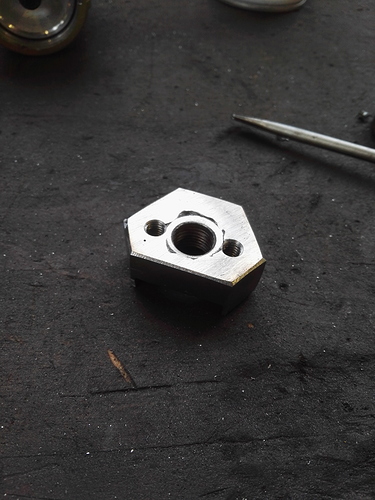

Made up some proper mounts for the air filter today

@DaleJeffree the bearings you can buy from any bearing store, they are called spherical plain bearings. You would just need to turn a flange on a lathe to be able to bolt it to the camber plate. Lucky everything was there on my coilovers, I just had to make the camber plates

For spherical bearing tops I use Minebea ABT12T®. A bit of a std. @DaleJeffree

Tim can make you up a set probably too mate

Hi guys, quick update.

The shocks are in

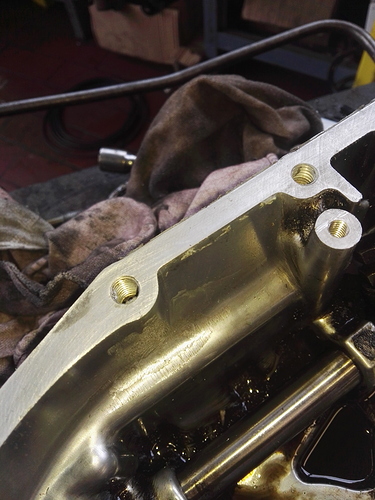

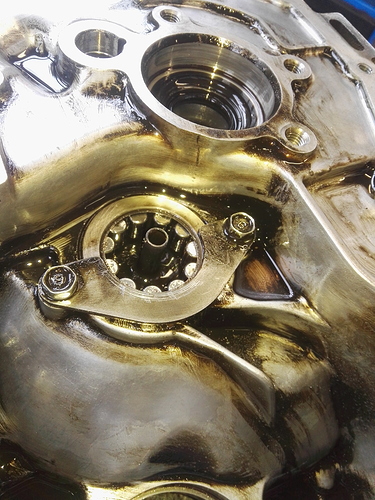

I got the gearbox finished with the copen 5.5:1 final drive, and I wanted to clear up a few things. First of all I the 1st and second gear from the 1.3 are strengthened, the gears on the output shaft are wider. Also the synchro ring for first gear is also different, it has a friction material on the inside, whereas the copen just has a complete bronze item. The gears from the 1.3 fit on the copen output shaft without any problems. For everything to fit the bearing for the output shaft on the motor side of the gearbox needs to be replaced with the bearing from the copen gearbox as the ID is different, and some material needs to be removed from the housing so the ring gear on the differential doesn’t foul, otherwise its very straightforward. Here are some pics, I should have taken more but time was a factor.

And finally work on the widebody is coming along, its subtle but looks good. In total its about 50mm wider

Nice work Mick. Interesting to know the 1st and 2nd gear are strengthened. I’m pretty sure I was starting to have issues with 3rd gear before other parts failed and have heard others talk about 3rd gear being the first to be problematic.

Awesome info!

I have the same final drive incoming, so the knowledge about taking a bit of material off etc is very valuable.

Could be the 3rd gear itself or the shift-action from 2-3 causing some issues.

The gear shift feel isn’t the most precise lol

As always awesome info!

that if … prepare to have a 3° gear replacement, it tells you someone who already had to use the replacement

I know some of the widebody pics were put up on facebook.

Has everyone baffled as it really doesn’t look like a huge change, but the wheel spec and spacer you’ve put on - the wideness must be there.

Well done!

In a world dominated by bolt on flares you’ve done it seamlessly.

At some point I’ll take the spacers off and pop the standard wheels on for a few pics, then you’ll really see the difference

Peoples minds will be blown then for sure.

Hiya gang, ive been pretty busy the last couple of months and my posts have been quite scattered with little information and just some pictures here and there. I figure its time to make a detailed post with everything thats happened this year.

Ill start by listing the problems experienced last season:

-

Gear ratios were not ideal for the short courses that I drive, I found myself stuck in 2nd gear most of the time with the motor bogging down when exiting tight corners and maxing out on the straights, smashing it into 1st or changing into 3rd both costing time because of the the gears were too far apart.

-

Lack of rear camber. The live axle on the AWD models has 0 camber, meaning if treated like a typical FWD using higher spring rates on the rear as a stop-gap to reduce understeer only creates problems. When high amounts of lateral force are generated during cornering the inside wheel begins to lift and the axle doesn’t remain parallel to the ground, tire contact on the outer tyre is reduced to the point that the car violently breaks loose beyond saving.

-

Too little negative camber on the front axle and too much inward roll radius. These combined were causing understeer during the braking phase of turn entry. I had previously installed eccentric bolts in the strut legs and maxed them out for negative camber, as a result the roll radius was moved inwards, adding the wheel spacers only increased this. Despite having relatively agressive negative camber along with some toe-out the tyres were still wearing more on the outer edge than the inner edge. I witnessed the tread depth on all four tyres wear away on the outer edge during the course of one season.

-

Ride height too high. The ride height seemed to be too high, while the roll centres were relatively low, during cornering the weight was pushing the car outwards rather than downwards. This was especially true for the rear, with the centre of gravity for the sprung mass being somewhere around the the height of the rear wischer motor while the roll centre is at the panhard bar. Until now lowering the car was out of the question because of the rear shock absorbers, none could be sourced that were short enough with an eye on the top and a fork on the bottom.

During the winter I spent alot of time reading and thinking of solutions. Putting together my App, krtuna.com I also learned alot. Armed with my copy of Fahrdynamik in Perferktion and my Tabellenbuch I went to work attempting to make alterations to the overall suspension to try and produce something that worked more harmonious.

A gearbox was put together using a combination of parts from the sirion gearbox and a copen gearbox. Before attempting I went on a hunt for information and I was told alot of different things, this is stronger, that is stronger, that is too weak, that doesn’t fit, you shouldn’t do this, you should buy that, and so on. As with many things on the internet, not alot was true. The gearbox went together easily, the output shaft/pinion and the crownwheel, along with 5th gear and the output shaft bearing were taken from the copen gearbox, 1st to 4th gears from the sirion box were fitted to the copen output shaft. The output shaft bearing was fitted to the housing, and the crownwheel was fitted to the Sirion diff centre. Everything else went together easily.

The parts from the sirion box that are stronger are as follows:

1st and 2nd gear are wider

Synchro for first gear has an added ring of friction material on the inside.

I believe the failure of 3rd gear has also been observed. The axial movement of the output shaft is restricted from one circlip, which holds the outer ouput shaft bearing in place, and the individual gears use plain bearings between the gears and shafts. I believe that too much axial play on the output shaft and too much radial play on 3rd gear on the input shaft causes 3rd gear to foul on another part and sets the failure in motion. I think by replacing the roller bearing on the engine side and the ball bearing on the outside of the output shaft with tapered roller bearings and using some shims to provide a light preload on the tapered roller bearings will eliminate axial play on the output shaft, and replacing all the plain bearings inside the individual gears with needle bearings to eliminate radial play would greatly improve the overall strength of the gearbox. Something I will attempt when this box lets go.

Onto the suspension…

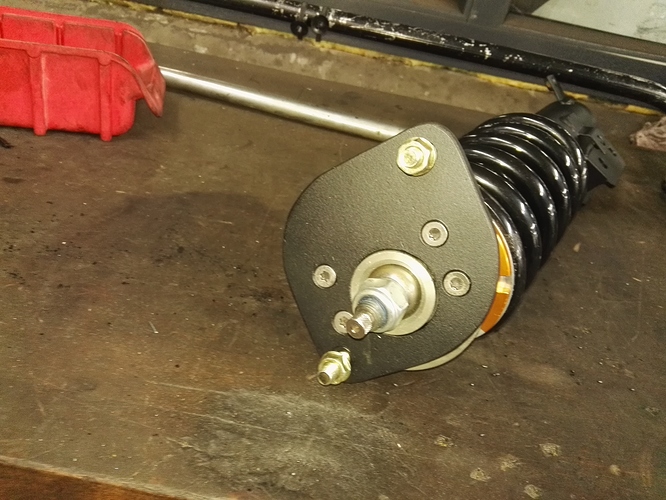

For the front suspension a pair of adjustable coilover originally destined for a subaru WRX were sourced and modified to fit. The mounts for the steering knuckle were made so the steering knuckle sits as close a possible to the strut leg to allow them to work properly at different steering angles. The strut tops were made with an inward offset to increase camber and move the roll radius outwards simultaneously.

The spring rate for the front was chosen to match the frequency of the rear springs, which was approx 2.5Hz. After doing some maths and seeing what was available, a pair of 50N/mm springs were purchased. They are harder than the rear springs, but they allow the rear to work properly and keep the tyres on the ground.

The eccentric bolts for the strut legs were retained to allow fine tuning of camber and it is now sitting at about -2.3°.

Spring preload on the front was set by observing the suspension travel. The shock absorbers had approx 80mm of travel between fully extended and the bump stop. I set preload to allow 30mm of travel from ride height to full extension, and 50mm of travel from ride height to the bump stop.

The rear suspension was the next step…

A pair of Suzuki motorcycle shock absorbers were purchased for a few reasons. They are good quality shock absorbers with bump and rebound adjustment, the bottom mounts are screwed on meaning fork mounts could be made, and the length is perfect.

Some lower mounts were made, which was a bit tricky because of the location of the adjuster.

The springs on the rear (eibach lowering springs to suit Fiat 500 Abarth, spring rate 220/250 lb/in) were cut down to achieve the desired ride height. The closely wound section of the spring was cut away, leaving the spring end closely wound enough to still fit in the spring seat.

The panhard bar mount on the chassis was modified to allow the panhard bar to be mounted at a higher point, so now the centre of gravity is lower and the roll centre is higher. Things are looking good.

To allow everything to work without fouling the body was widened approx 25mm on each side. Spacers were fitted on the front quarters to bring them out, and all the spot welds on the rear were drilled out, the rear quarters re-positioned, and welded in place.

To save money on painting I chose to wrap the car in a matt-chrome red

Last weekend I drove to my first race of the season and the car performed incredibly, very light and predictable oversteer, and cornering was much better. The rear axle did its job (finally), the rear tyres stayed glued to the ground, as did the front. Acceleration was dramatically improved, I can now launch the car without the motor bogging down. Third gear may be a tad too short, but I find it much better than before. The only problem was a little scrubbing on the rear, but that will be fixed soon enough.

Videos will be coming soon

Just wanted to hear that again.

Fantastic write up.

Excellent work as always.

Yes, at one point I spoke to an “expert” whose suggestions were vague at best. When pushed for more specific information the conversion ended abruptly. Either they did not know or chose to withhold information. Both situations are very uncool. I always help and share wherever possible, and never claim to know things that I do not know. But the world is full of strange people, I think the both of us are among those strange people

The culture established here is excellent. It is good to be able to talk things through. I really want to hear constructive feedback, while I only get a little here, I can definitely say I do get a lot of excellent criticism (that I take on board). That feedback aligned with knowledge and experience brings understanding. I hope the culture here of understanding and wanting to understand keeps moving forward.

Looking forward to the videos (I have some here from our track day but have not had a chance to even look at them let alone upload).

Amazing work Mick!