Hi guys, so I actually started on the build today, didn’t get as much done as I had hoped for because I ran into some problems.

Im sure you all know I already have another thread going but I would like to keep it for random questions and general discussion, and use this thread to document the build as it progresses.

Once I have finished I will make a detailed “how to” thread in the Daihatsu wiki listing all the parts required ect.

First up I did a quick test fit of the 15x7 +38 rims, @b_hoves told me on the 2WD wheels this wide would have fitment issues on the rear, but luckily the AWD trailing arms sit inward a bit more than the 2WD. The wheels fit well, almost flush with the guards and there is about 1 to 2 cm clearance for the trailing arms.

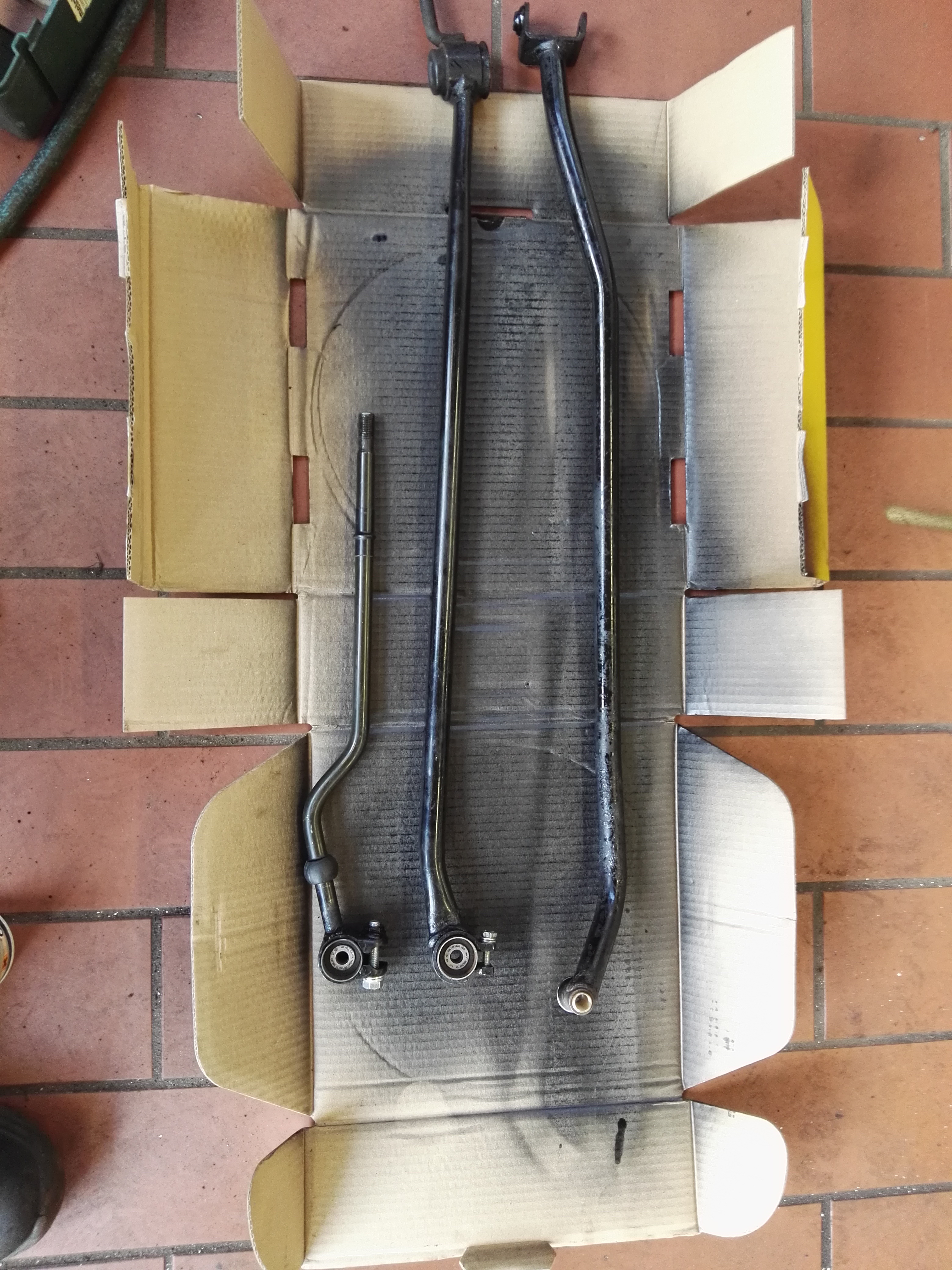

Next I dropped the tank, tailshaft and the rear diff. This is where I ran into my first problem.

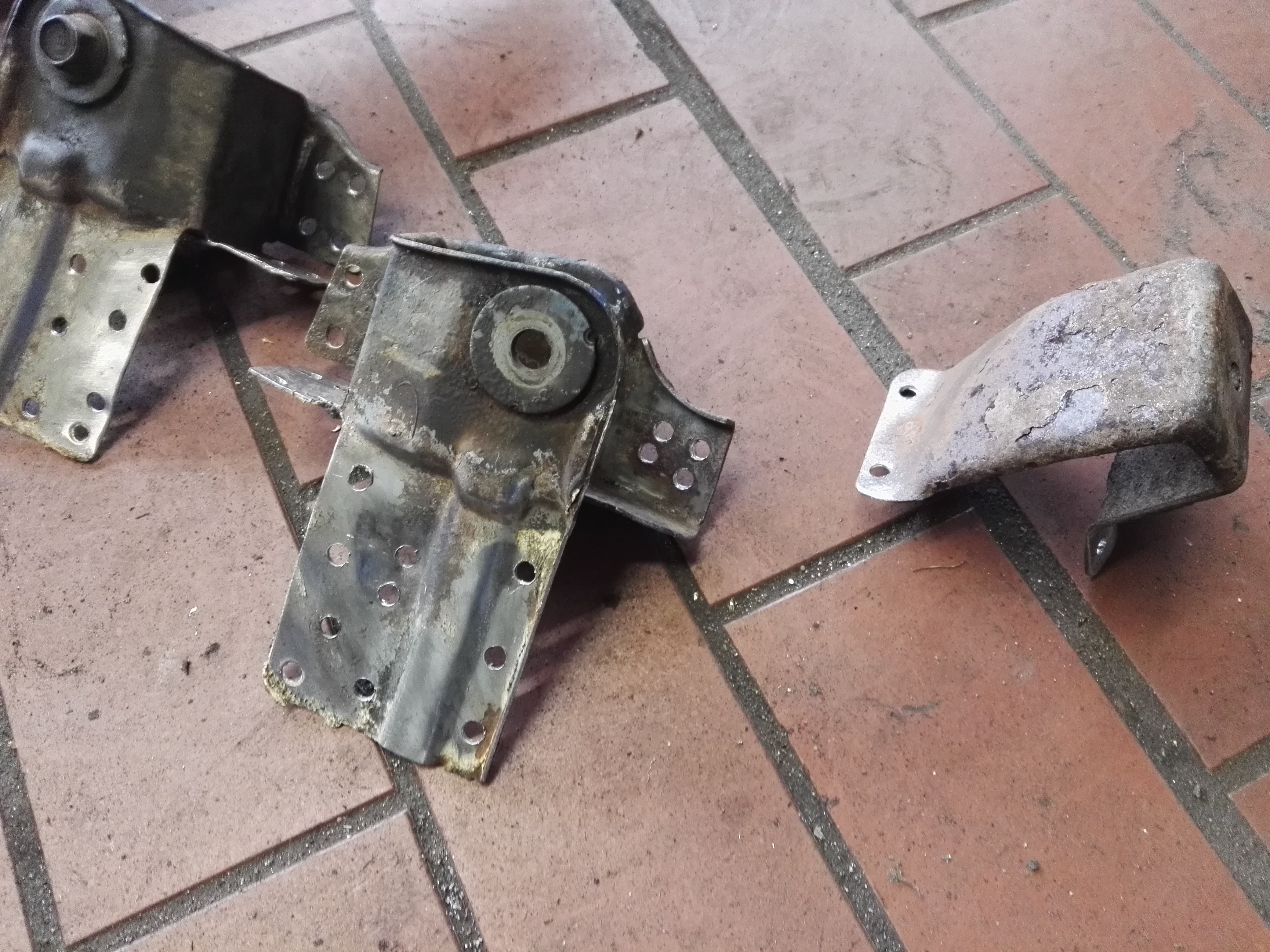

The bold was rusted in the trailing arm bush on the right side and I had no choice but to cut the bolt as it was just turning the bush and spreading the mount as I unscrewed it.

Now I am on the hunt for some trailing arm bushes or complete trailing arms

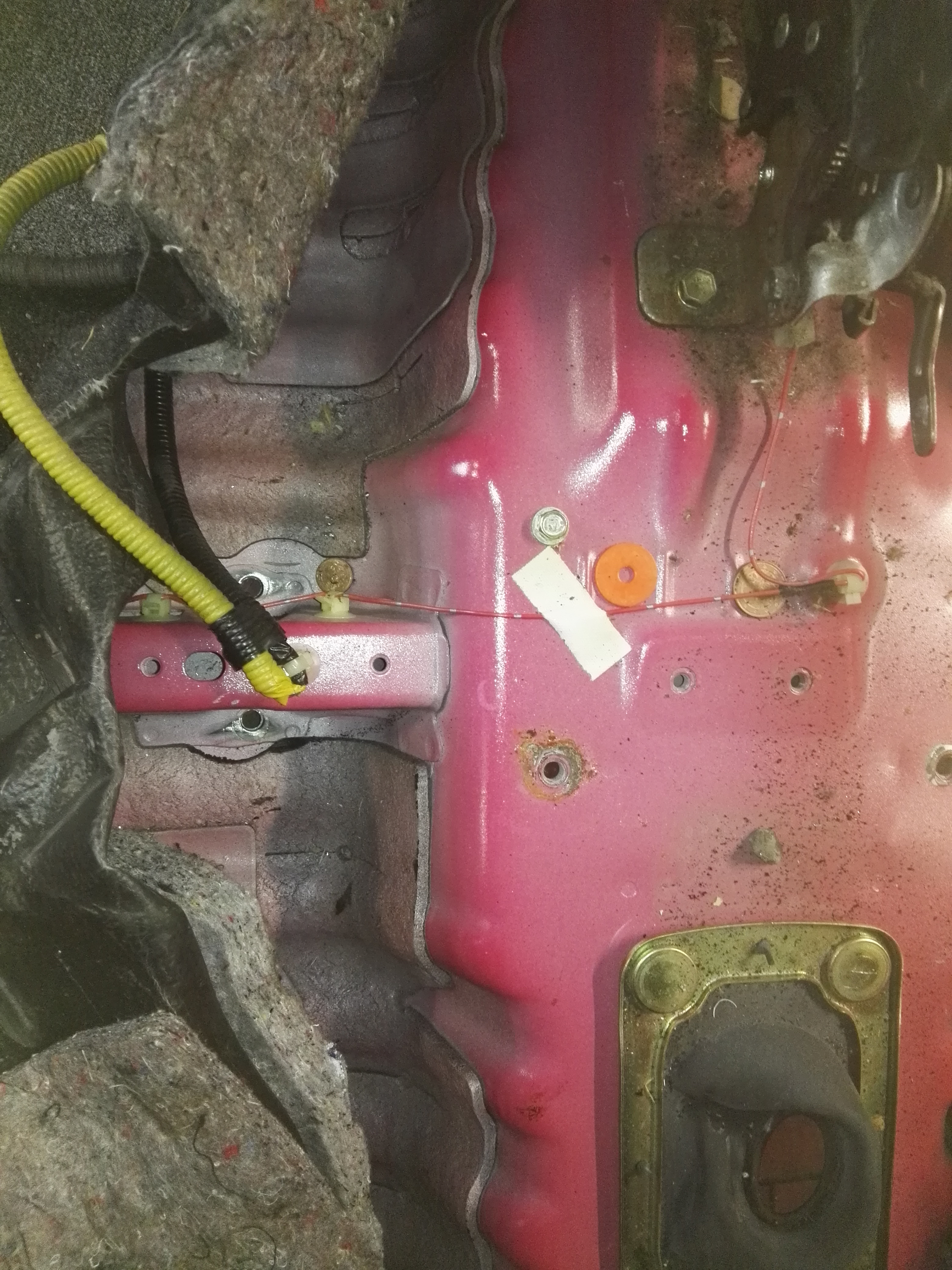

Then I went ahead and started cleaning the mounts with the old wire wheel on the angle grinder, then started centre punching and drilling all the factory butwelds (not before taking about a bazillion measurements of course  )

)

It was definitely not fun drilling out approx. 50 butwelds above your head getting sprayed with swarf for over an hour

Here is a photo of the dolly I made yesterday sitting underneath the rear

Pushed out the blue car and pushed in the red car.

I had enough room to weld in the right mount and the mount for the panhard bar without removing anything in the rear end other than the muffler.

Im not completely satisfied with some of the welds on the panhard bar mount, some of the holes were too close to the edge and burnt through a little bit as you can see, but unfortunately it couldn’t be helped and will have to do

Anyway, that’s as far as I got today before running out of time. In order to do the mount on the left I will need to drop the tank, but even if I did get it done I wouldn’t have been able to bolt up the diff because of that shitty bolt rusted in the bush