Greetings and welcome to my build, I recently bought and old and beaten up L500 the color is kinda red (two resprays I think). Small wrecks, one on the rear and one on the front, passenger side. I got it really cheap, but it was as basic as ever possible and a lot was really badly fixed!

So as soon as we bought it we changed the entire back exhaust and tried to return it back to stock. (Original exhaust was leaky and fixed with rebar and wire). The CV joints were both busted, the wheel arch was found full of grease one night. At a local Daihatsu parts store bought most of the maintenance stuff (CV joints, gasket kit, filters, etc.) We also changed the wheels and fitted new tires, have a small rubbing problem though.

Later I changed the front and rear shocks, did it myself, was pretty scared about the spring coming loose or something similar but it turned out OK.

Finally the guy sold me anything to milk me for money, but we couldn’t find the originals, so we had to modify them, a quick trip to the milling machine and “problem solved” I still have to check if the camber changed when I do align the car.

The back shocks were pretty much bolt on.

After all this changes the interior was to be fixed, wanted to install central locking, power windows an alarm a new “Headunit” an amplifier, new speakers (the car came with an aftermarket HU fixed with some sheet metal hanging out and only one speaker was working) The car also had an alarm but it was almost completely disconnected.

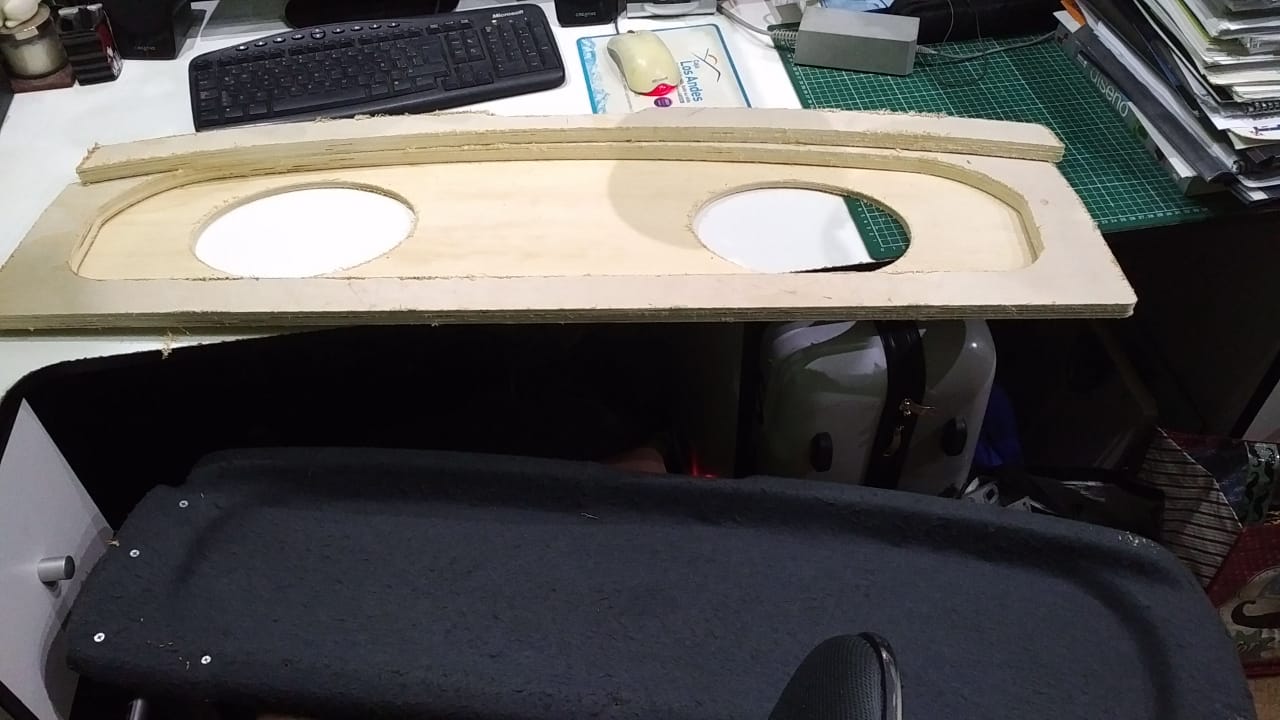

The rear boot cover was also really bad so we decided to build a new one out of plywood, whipped out the CNC router and this came out:

After some carpeting and a little bit of care the results (to my eyes) are quite pleasing.

The roof lining also required some attention, the old one was ripped off and we glued a new one

The turn signal switch was also a big problem, the original one was really worn and broken so I bought what was available, a Charade G102 multi switch thinking I could easily rewire it and things would be all good and merry, after some fiddling around it turns out it’s really as different as it gets, so I had to delete the hazard switch and remove quite a bit of plastic, at least electrically it works as intended, so I just need to make it fit, will post the results as I haven’t tried it yet.

I will keep posting soon I hope posts can be edited to add more information and improve formatting.

Best regards!

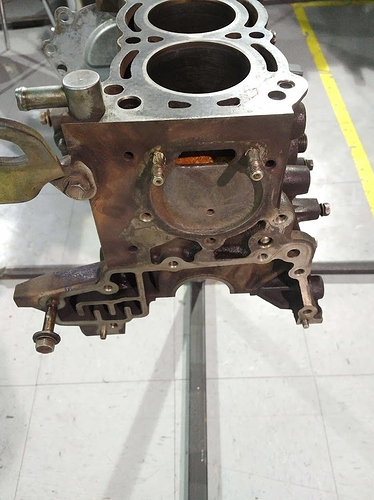

It’s comming from the crankcase ventilation coupling and I don’t understand why there is oil pressure there, we disconnected the tube going to the air box and blocked it with a finger, still oil comes out the base of this elbow.

It’s comming from the crankcase ventilation coupling and I don’t understand why there is oil pressure there, we disconnected the tube going to the air box and blocked it with a finger, still oil comes out the base of this elbow.