Great news: I got something to write about! And it’s good

SHED UPDATE

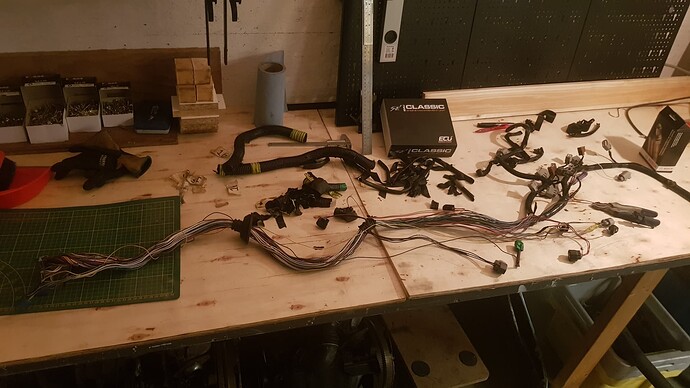

The Blyatsu has been sitting inside the garage since December, and the reason why it’s been sitting so long is because my shed just wasn’t ready to work in. Sure, there’s more space and stuff to work with than the garage I did my swap in, but it was just a mess of stuff and unfinished business. So, I started working on a workbench, and this is the result:

Excuse the mess, I was a bit excited

It’s about 85cm deep and 360cm wide, pretty nice! It’s hard to see on this picture, but there are two small benches on the side and opposite to the main workbench, creating a nice C-shaped workbench. I really wanted this because I like having multiple ‘spaces’, yet being able to use all the space at once (like for wiring). It took quite long before I finally finished it, because of (the lack of) time and because it was a real mental challenge. Not in a way like I’m suffering from depression, but with (new) things like these, I don’t really know how I’m supposed to do it, which stresses me out and makes me postpone progress. I can just sit around and stare at pieces of wood for an hour, just trying to figure out what the hell I’m supposed to do. Incredibly exhausting. But, it’s mostly finished and ready for use!

CHANGE OF PLANS… AGAIN

So, about the car then. Motivation has been low, but suddenly it kind of skyrocketed, and ever since I’ve just been busy with “what do I need to do to get this thing back on the road?”. The main goal for this winter was to install the EMU classic (standalone ECU). When I was doing some prep work for the wiring, I started to think (dangerous, I know). What’s really the point of fitting a standalone ecu to a car with relatively low power? Sure, compared to an EJ, the 3SZ is a big block, but it’s stil not a big block. And well, when timing is right, things like this happen:

What you see here, is a Honda K24. I happened to have an itch for moare bigger at a time when I had some money to spare and a friend of mine put this up for sale. You could say this was an impulsive purchase. So impulsive in fact, that I didn’t tell anyone, because I was kind of ashamed since this is pretty hard to justify in terms of money.

Anyway, there’s a LOT of work to do for this to go in, so better get started! Starting with wiring, because I’m already working on the ECU anyway.

WIRING

So, for those of you who are wondering how the hell I wanted to fit a K24 under the hood of an L7, when the 3SZ was already a challenge in terms of space: I’m not, but today is the 1st of April ;). The engine in the pictures above is actually my friend’s, who is fitting it in his Lotus Elise (also a tight squeeze). I’m sticking to the 3SZ!

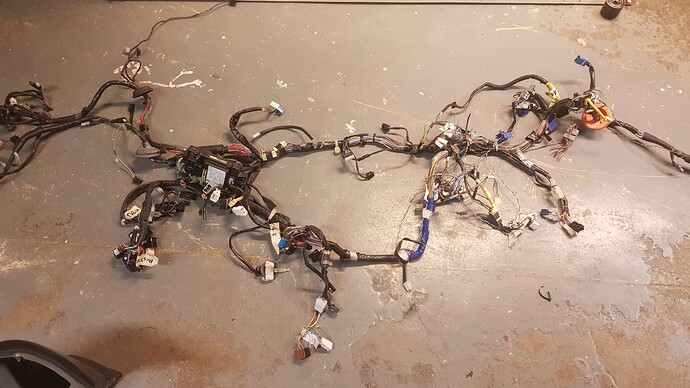

I already took out the engine harness a while ago, so now it was just a matter of stripping all the tape and sleeves

I’m taking off all the factory tape/sleeves/protection from the harness because of three main reasons:

- It looks like shit imo

- I need to run some new wires through and delete some other wires

- I need it to be more flexible, and in some cases the cables need to go to a different location

On the left you can see a bit of OEM sleeve/tubing, on the right you can see the new sleeves I already fitted a while ago. The entire harness will be wrapped in this kind of sleeve. Exciting!

Be gone, factory junk

When I was mostly done with that, I remembered something quite important: I needed to take out the interior harness out as well  . It’s not a necessity for the new ECU, but I wanted a different harness anyway since a lot of the wires had to do with the whole CANbus nightmare, which won’t be needed anymore, or just aren’t used at all. I also want to make a few additions, like a single plug for the headlights (quick release, bro).

. It’s not a necessity for the new ECU, but I wanted a different harness anyway since a lot of the wires had to do with the whole CANbus nightmare, which won’t be needed anymore, or just aren’t used at all. I also want to make a few additions, like a single plug for the headlights (quick release, bro).

So, out goes the dashboard. Taking out the dash has become a routine task over the years, but damn, I forgot about how impractical and bulky my wiring harness was

Notice the harness forms a bit of a ‘loop’ in the middle

This loop made really put my mood to the test. I think they made this loop because the YRV’s dash (from which this harness came) is a bit taller than those in L7’s, for example. However, L7’s and Sirions (M1) did not have this loop, making life a lot easier. A lot of swearing and some bruises later, I got it out!

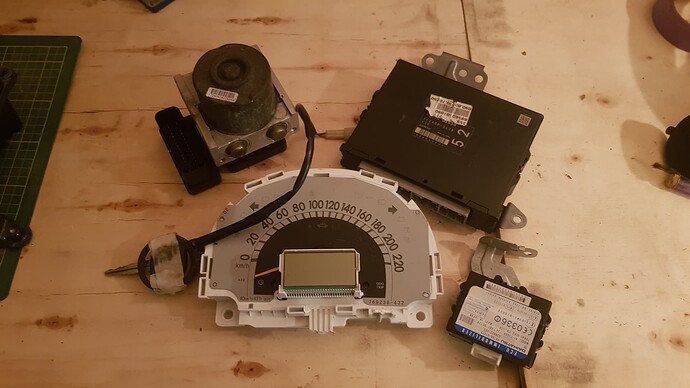

These are all the bits I needed to make the factory ECU work properly. Apart from the ECU (obvs), I can now get rid of everything! Thank god

This is the entire package that I will fit to the car. The EMU classic, a wideband O2 sensor and a Sirion wiring harness

I stripped down the Sirion harness the same way I did with the engine harness, which took quite some time. The next step is probably remove/add wires if necessary, but that requires some staring at wiring diagrams, which I didn’t have time for today. It doesn’t seem like much in terms of progression, but I really enjoyed working on the car again today, and I’m really motivated to get it back on the road again soon!

ANNIVERSARIES

Tomorrow (April 2nd) is the Blyatsu’s 21st birthday, and the day after that is my 23rd birthday. I didn’t think the Blyatsu would look like this on its birthday (I don’t really care about its birthday, but I just mean in terms of how long it’s been sitting for), but on the other hand it’s not that far from driving again, really.

Also, today is my 2 year anniversary of renting a shed, and

tomorrow it’s 2 years ago I bought my YRV donor!

Ah yes, time flies.

Well, that’s it for now! Maybe not all that interesting, but it’s nice to be motivated again. I’ll keep you guys updated!