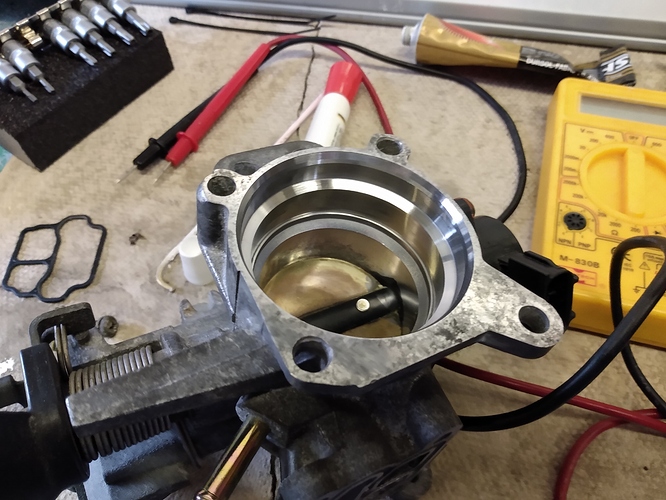

With the O2 sensors and MAP sensor deemed to be in the correct ranges, my attention turned to the throttle body itself. I could see that the main throttle body butterfly was shut with the accelerator pedal in normal position, and pressing the accelerator pedal caused the revs to rise as expected. With the diagnostics plugged in, I was getting a reading from the throttle position sensor, indicating that it was working correctly too.

This left one remaining thing - the idle control valve.

These have a bad reputation in Sirion/Storias for seizing. If you google ‘fault ICV’ the symptoms described are remarkably similar to what I was seeing here, so the finger of suspicion slowly turned to the ICV. What was concerning was that by this point I had three (!) throttle bodies, all of which had the same issue, with idle stuck high. Surely even I wasn’t so unlucky to have identical problems with three separate parts?

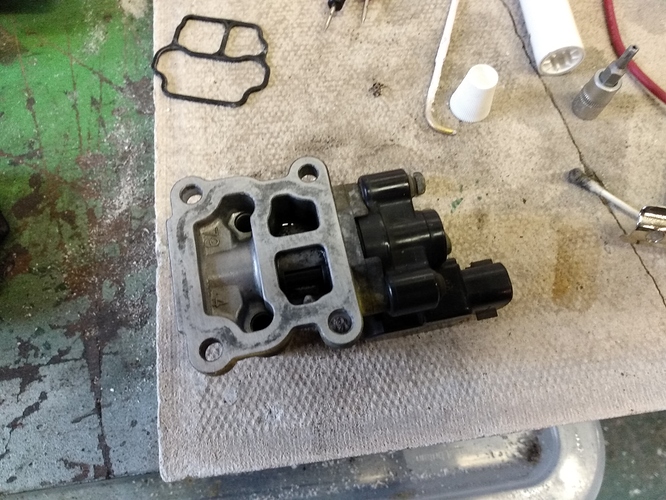

I had a look for just the ICV housing - its a separate part of the throttle body, held on with 4 cross-head screws. once undone, there is a gasket that keeps the coolant that flows through the ICV separate from the air intake, because it would be BAD if that mixed!

The ICV part of the throttle body is shown here

It is the thing with the grey plug and 2 coolant hoses running to it, directly above the barrel of the throttle body. Removing the hoses and multiplugs to the throttle body and then unbolting the TB from the inlet manifold allows me to remove the throttle body and get it on the bench to disassemble.

With 4 screws removed - they are tight, but will eventually yield - the ICV housing comes off

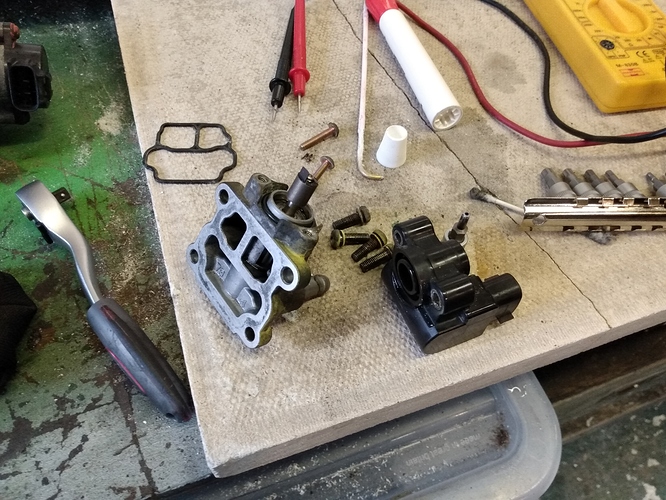

Then it gets fiddly. To get at the actual valve you need to remove the black stepper motor which is what the grey multiplug connects to, and which controls the ICV in normal operation. This is held on with 2x torx head screws, but these are not normal 6-spline torx bits, they are anti-tamper screws with 5 spline grooves. Finding 5-splined torx bits was a bit of a challenge but I eventually got a set and undid the wretched things, allowing me access to the innards of the ICV

with the stepper motor removed (black bit) I could see there was a magnetic spindle that controlled the actual valve. I gently began twisting this between my thumb and index finger and it wasn’t moving at all - this should rotate 360 degrees with the stepper motor removed, so I squirted a small amount of plusgas down the bottom port (apologies for blurry image!)

then tried to twist the spindle again, I was rewarded with a small bit of movement, so gave it some more plusgas and twisting until with a small crack noise, the valve unstuck itself and would now rotate 360 degrees! This is what it should do in normal operation. What had happened with THREE (!) separate throttle bodies was the idle control valves has seized in position, the poor stepper motors weren’t powerful enough to unseize the ICV and so the valve itself was stuck wide open.

This caused the idle to be way too high, as too much air was able to bypass the main throttle body butterfly. The surging I was seeing before was the engine ECU cutting power to the injectors momentarily to try to bring the idle speed down, but as soon as power was restored the idle speed shot right back up.

I reassembled the throttle body with the stepper motor, newly unseized ICV and a fresh gasket (that looks kind like the trollface meme I think?), refitted the 4x cross-head screws and tightened it all back up. I bolts the throttle body onto the inlet manifold, reconnected the various hoses and multiplugs and turned the key…

and after a couple of minutes was rewarded with a beautiful 900rpm idle speed!

I repeated the process on the second throttle body, unseizing the valve with some plusgas and gentle twisting of the spindle. Its easy to do, but you need to have 5-splined torx bits which I’ve found to be rather difficult to source. I have a set now, so if anyone else has a similar issue let me know and either you can post me your throttle body or I can post the bits to get at the ICV and unstick it. Its not possible to do without removing the stepper motor though