Because writing in retrospect… of course it’ll be skipping back and forth with information zig-zagged across time… hope it doesnt become confusing but I rather be comprehensive than skip key milestones.

So i’ll take the time to introduce an aspect which made forced induction possible for me anyway. With boost (basically more air), we needed more fuel. I initially toyed with the idea of both water injection and methanol… and the youthful me thought it would be a brilliant idea. This meant adding injectors in to support the different types of fluids and my solution to this was 2 extra injectors. Yep, 3 cylinder banger with 2 extra injectors making 5 total. While water and methanol were nothing novel, it was purely for academic gain. This young me idea was actually only a year or so ago… the complexity definitely overwhelmed and got the better of my ambitious ‘idea’. It was way over the top and stupid. None the less, I capitalised on the work to include the injectors to instead do staged fuel injection as boost came on.

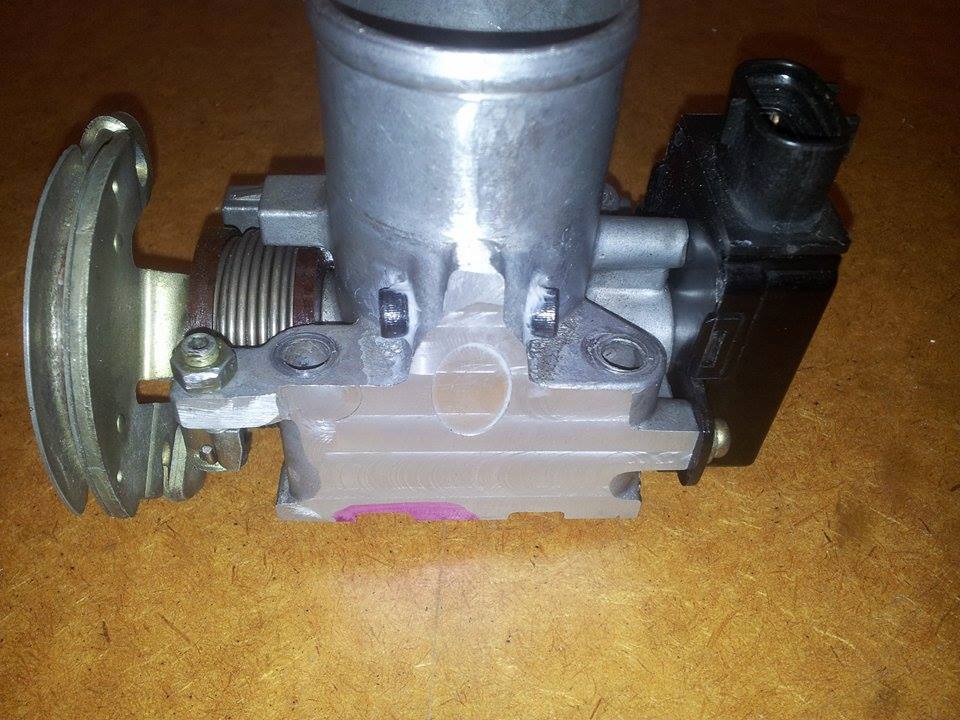

Here is the injector and a boss turned on the lathe. The feed was just an aluminum injector rail cut down.

!

A barb was tapped into the end and a bracket made. The welsch(?) plug was punched out and the injector drilled and tapped in with 3 bolts, sealed with RTV.

!

Just look at that beautiful view down the throttle body! So the idea was that this injector sprayed methanol. This would go directly into the intake stream for best atomisation(?)… basically mix well with the inflow.

The water injection would have been undertaken by another injector under the throttle body. The original one was cut down, plugged up where the cold idle wax thermostat was with aluminum pressed in, and finally milled square.

!

Another view. Similarly you can see that another aluminium rail cut and tapped with a barb would feed it - in this case it was supposedly water… The more I describe this idea, the stupider it sounds now! haha

!

Another view

!

Back side view with throttle body sensor there.

!

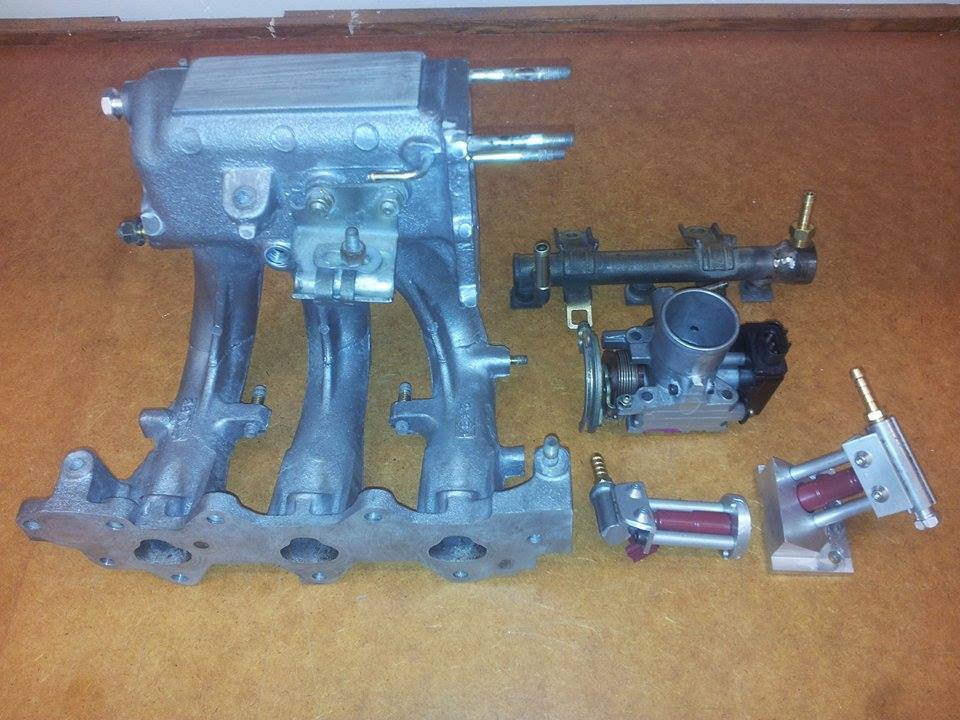

In components laid out. You can see I also modified the factory injector rail which included a welded bung at the end. This deleted the factory fuel pressure regulator and allowed a proper return system (provided we add the adjustable regulator in future).

!

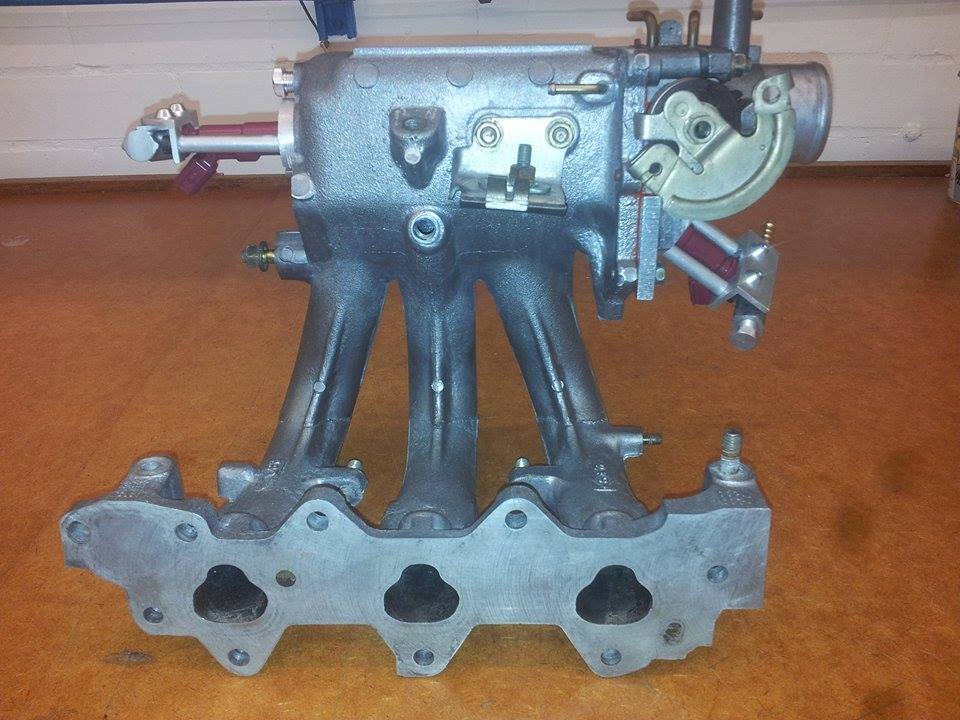

The intake! what a beast!

!

Of course, I hinted that the idea of meth and water was soon abandoned… It did however provide excellent means of staging fuel control. If your injector is too large, it’ll struggle to give a good spray pattern meaning your car(well engine) wont ‘drive’ smooth. An analogy would be like filling a drinking cup with a bucket… its not going to be smooth and very hard to control. Conversely, if you fill a drinking cup with a… say 1.25L bottle, its much easier to control while still having enough overhead to fill it quickly, if need be.

By using factory 660cc injectors on the original injector rail, it meant for a smoother idle and cruise due to their relatively small size. The throttle body injector and side intake manifold injector both used Sirion 1.0L factory injectors. Under normal operation, the 3 primary injectors are actually on batch fire. I simply staged the throttle body and side-intake injectors on sequentially as needed with a custom boost gauge and arduino.

I’ll get back to the turbo first but I’ve now presented the basic fuelling side. Oh it uses factory fuel pump and an ebay adjustable fuel pressure regulator. I’ll add pics of that next time. I got to collate photos exhaust first. The fuel and breathing must be sorted to accommodate performance gains.

Bonus photo. When the car was originally an ED10 carby. I made a 3" intake and it sounded so good. Carby was so crispy and a pleasure to drive because it was pure mechanical rawness. Its noted that this block was the donor to the franken-mira motor as noted in opening post.

Until next catch up,

derku.

modern goodness

modern goodness