Getting back up the mountain after any trip down weighed heavy on Gormsby’s mind. With the engine in his daily rebuilt he had one car with about 180hp which used 1 litre / 10km which would get up easily and the MIra with what felt like 25hp that struggled to get up but was doing 20km or better on 1 litre (it felt on par with another MIra which had seen 23hp on a dyno). His age put him in a good insurance bracket for the car, it was great to park, was of little concern to him if scratched by his students at school and it’d proven to be cheap to run. He figured that it might just make economic sense to keep the Mira. If only he could so more power/torque to get up that darn big hill.

Having played with increasingly longer induction tract lengths on a friend’s proper championship winning hillcliimb car and found noticeable torque gains which were verified on a dyno a cheap solution was sought to the lack of torque. A bench mark second gear run was done on Henry Robert Drive and the road side white pole where a change back to first was needed was noted. Bring on the 40mm PVC plumbing.

The end trumpet was made in the lathe by pushing a pipe center in the tail stock up against the short section of PVC while using a heat gun and it rolled nicely in one take. Some Chinese silicon bends ordered on fleabay, a K and N generic filter found and rigid pipes wrapped with sisilation tape to reflect heat.

The difference was never objectively recorded but many extra white posts were passed by. Suffice to say it worked so well that another 600mm of pipe was added by sending the 180deg curve further to the passenger side. If only all performance increases were of the low dollar value found in this one.

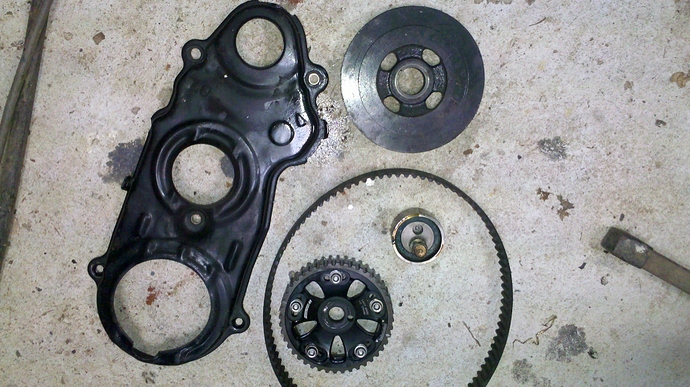

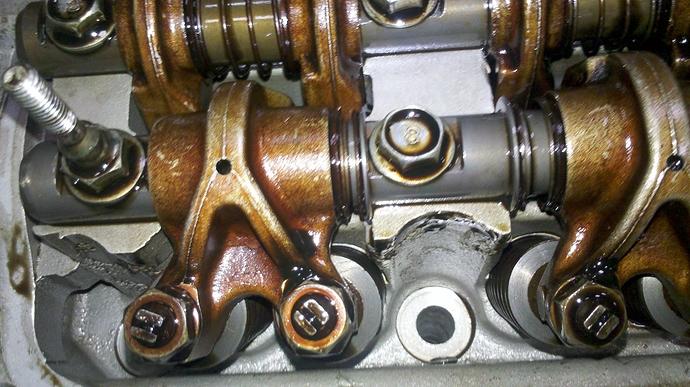

The ef-el head was removed, sump pulled, pistons/rods lightened/balanced, rings replaced, valve guides removed, extensive porting undertaken, combustion chamber smoothed, head decked, light vavle spring retainers installed, slightly improved cam installed, someone else’s homemade extractors matched ported and 1 7/8" exhaust installed, inlet manifold tidied up, throttle body bored for 1mm bigger butterfly, butterfly axle slimmed way down and counter sunk screws added, aluminum vernier cam wheel added, adj fuel reg, cam rocker shaft lower oil holes plugged, more material removed from flywheel then balanced, cam rockers lightened/balanced, new timing belt/bearing, new leads/plugs. Most of that fab type work was done in the school workshops at lunch time and other than gaskets, new pulleys/belt, plugs and leads all else was free from parts bins. It liked an awful lot of timing advance, revved harder, power moved further up the revs, Zero to 100km’hr now achieved in well under 20sec now and no low down torque at all. It had to scream to keep it going.