Okay for those that have seen the series “Seven Periods with Mr Gormsby” you’d know that his daily is a Wolseley. From watching the series few people would know what he does in his spare time. Outside of being a high school teacher he’s been spending a lot of time and as little money as possible putting together a L200 Mira for motokhanas, khanacross and hillclimbs. So that’s not quite side by side track racing (and hence “not quite track”, but Gormsby’s a tight arse and doesn’t want to to run side by side with others (he might be a bit to scared of that but you’d have to ask him yourself). The car was never intended for this purpose and he’d purchased it with the intent of keeping it for only a few months while his main car was off the road. Stay tuned for the full story and maybe even build progress or event updates

.

Okay  Interesting

Interesting  you have ignited my curiosity so definitely following this, and those wheels

you have ignited my curiosity so definitely following this, and those wheels  what specs are they?

what specs are they?

Nice man, I do love a L200, those wheels look huge, likely just the car haha.

I ready to learn more Mr Gormsby lol.

15" x 6.5 with +32. Cheap and heavy 7.2kg for the rim only (big thanks for those Tim - having them was pivotal to deciding to go in the final direction).

Wheel brand is Advant Racing. Not sure what model… Will show the new 7" wide 5kg Rotas later. Tires in the pic are 195/50/15. New race radials are same spec but oversize and measure 204mm wide. Much work to make them fit.

Gormsby had vowed never to modify the L200 and the plan was definitely to keep it for only a short time - or so he thought. Jan 2012 and $700 for a hail damaged L200 with under 100 000km, rwc, 3mnth rego and pink/green splash vinyl down the side. It was collected from the sunshine coast qld from a guy with a collection of Suzuki motos and it had been his pick up stuff car. Driving back to Mt Tamborine Gormsby knew the vinyl had to come off as soon as he got home, but all okay as that’s not a modification really is it? He was a bit concerned about its lack of power and wondered if it would get up the steep Henry Robert Drive - first most of the way up. Once home he goes up stairs to make coffee and comes back down to devinyl it. But alas there is a huge pool of oil. No drips on the drive way and nothing on the road. But oil seems to be coming from the rear main. Engine and box have to come out and it is found the rear main seal is cocked over and the flywheel has worn a hole through it. Must have just made it home. Well with the flywheel out, the first gear hillclimb experience and Gormsby having a lathe, there were iron fillings to make.

The first one was about 3kg and the second two point something kilograms. It went a little better and had greatly improved engine braking.

Having completed an apprenticeship as a spray painter straight out of school he couldn’t help but do a full engine bay respray.

The handling was woeful also (12" tires made in Pakistan, good grief! Tires are fundamental!) and it was figured that being able to get a run up for the corner at the bottom of the mountain would be desirable. So strut to hub top holes were elongated and some tops modified for 2.5 deg neg camber.

It helped a little but was still a pretty sad experience driving the thing. Now it was starting to get warm. Some measuring of the existing radiator and an internet serach found that an aluminium one from another make of car was the right size and due the popularity of that make it was inexpensive. It did mean though that the mounts needed altering. The K frame hole was of no use. Two matching holes were added in the frame but their location was moved forward at the base 10mm due to some hose clearance issues. Not a great car now but “less awful”.

Pls Mr G. More

Ur 201 looks v nice and I’m interested in how to make them handle without wasting money on coilovers

Keep posting man and go hard !

Always tires and good dampers/shocks, but those are a given. But that’s not the sort of mystery you were looking for. So here goes…

…,perhaps this tip should be revealed latter, but anyway, the single biggest improvement was 500 lb/in rear springs. So there it is a “big increase in spring rate”. Well the story of this is a little interesting and will be told to all if they can stick with Gormsby’s dribble.

mine atm I’ve been told stiffen the rear n front well not much apart from drop

mine atm I’ve been told stiffen the rear n front well not much apart from drop

Front are 115lb and as said rear are 500lb. New 150lb frt and 550lb rr, plus a hollow carbon bar to make a rear sway bar, are things in the mail right now. Typically the front is kept just soft enough so that in 99.9% of use the thing does not bottom out. As it gets quicker (and lower) the front rate has to come up. As in any FWD front has to be soft and rear stiff to get the weight transfer to be sent to the front at all costs. It picks a rear wheel up in just about all conditions when pushed.

I got my google images to embed, go to the image in google drive, make sure that the security is set to viewed by anyone then right click the image and go copy image address. Then once back on the forum click upload, then from the web and paste the image address. Alternatively you can just upload the image straight to the forum

Getting back up the mountain after any trip down weighed heavy on Gormsby’s mind. With the engine in his daily rebuilt he had one car with about 180hp which used 1 litre / 10km which would get up easily and the MIra with what felt like 25hp that struggled to get up but was doing 20km or better on 1 litre (it felt on par with another MIra which had seen 23hp on a dyno). His age put him in a good insurance bracket for the car, it was great to park, was of little concern to him if scratched by his students at school and it’d proven to be cheap to run. He figured that it might just make economic sense to keep the Mira. If only he could so more power/torque to get up that darn big hill.

Having played with increasingly longer induction tract lengths on a friend’s proper championship winning hillcliimb car and found noticeable torque gains which were verified on a dyno a cheap solution was sought to the lack of torque. A bench mark second gear run was done on Henry Robert Drive and the road side white pole where a change back to first was needed was noted. Bring on the 40mm PVC plumbing.

The end trumpet was made in the lathe by pushing a pipe center in the tail stock up against the short section of PVC while using a heat gun and it rolled nicely in one take. Some Chinese silicon bends ordered on fleabay, a K and N generic filter found and rigid pipes wrapped with sisilation tape to reflect heat.

The difference was never objectively recorded but many extra white posts were passed by. Suffice to say it worked so well that another 600mm of pipe was added by sending the 180deg curve further to the passenger side. If only all performance increases were of the low dollar value found in this one.

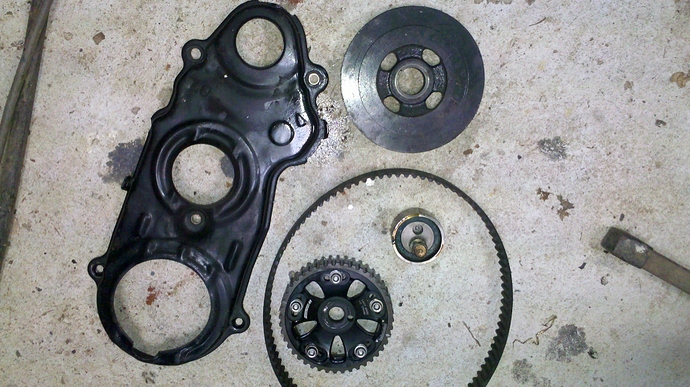

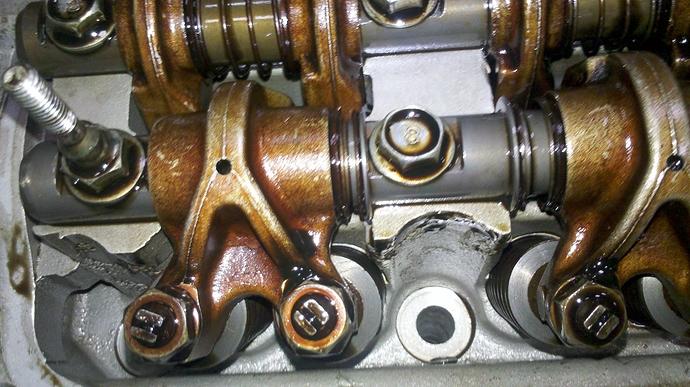

The ef-el head was removed, sump pulled, pistons/rods lightened/balanced, rings replaced, valve guides removed, extensive porting undertaken, combustion chamber smoothed, head decked, light vavle spring retainers installed, slightly improved cam installed, someone else’s homemade extractors matched ported and 1 7/8" exhaust installed, inlet manifold tidied up, throttle body bored for 1mm bigger butterfly, butterfly axle slimmed way down and counter sunk screws added, aluminum vernier cam wheel added, adj fuel reg, cam rocker shaft lower oil holes plugged, more material removed from flywheel then balanced, cam rockers lightened/balanced, new timing belt/bearing, new leads/plugs. Most of that fab type work was done in the school workshops at lunch time and other than gaskets, new pulleys/belt, plugs and leads all else was free from parts bins. It liked an awful lot of timing advance, revved harder, power moved further up the revs, Zero to 100km’hr now achieved in well under 20sec now and no low down torque at all. It had to scream to keep it going.

Thats a darn big hill Mr gormsby lives on too I didnt even take the move down the bottom of fear I wouldnt gt back up again

Along the way there have been some mods that never got enough traction to finish. With no less than four inlet manifolds lying around and having been given some pre-preg carbon fiber the task of placing some ram tubes inside the manifold was undertaken. Some molds were machined up, layup completed, vacuum bag done and trumpets baked. The outer rim of the trumpets did not come out right. Learning point from this - watch for bridging across short concave section and remedy by making dam type inserts.

The chopped up manifolds were dumped, the trumpets trimmed, weighed (less than 20gm each) and stuck on the shelf as a reminder.

A more successful effort at ram tubeswhich bought a few extra hp and better torque curve as verified on a dnyo as compared to the old steel ones. Gormsby made serveral versions of the airbox which bought more power and helped quieten the car enough so as not to get into trouble with side of track sound meters. This is the second last one (final prototype) with the final version being a combination or basalt and carbon fiber. A cooler induction charge was another consequence as was more power. The pvc crossover tube going to other side the engine bay and air cleaner was replaced by a custom kevlar one, plus an air box taking cold air from in front of the car , and resulted in apparently a couple more hp seemingly because of less heat sink into it. Can’t have been too bad as the owner despises me but to my knowledge still uses many of my parts I hade

And onto the suspension - take one.

Some Hyanudai rear Koni Sport Dampers were added and spring coils removed (cutting coils lowers and increases rate). Front struts were opened up new bronze bushes made, legs shortened, spring seat lowered, coils removed from springs, damper shafts machined down, new microcell bump stops found to replaced the smashed to pieces rubber ones, new thread machined onto the ends and prob 15 or 20wt fork oil added (what looked like grey-black water had come out and what went back in was the thickest that had been sitting on the shelf at the time - without using engine or gearbox oil). The shorter struts bought the front down 75mm and still gave 70mm upward travel before hitting the bump stops and about the same travel in drop. Mazada mags fitted.

The new big wheels rubbed with the desired neg camber so some angle was backed off at the strut-hub connection and a bit added by cutting and shutting the strut tops. Rubbers were linished down a bit and a Delrin spacer added above to lower it in the front a bit more without taking suspension travel away. <img

This lets the top move inward for some more neg camber and rearward slightly for more castor

(note that in the above picture the top is pushed outward on someone’s car whereas it ended up being pushed nearer the center of the car)

And though better it still “sucked”. Turn in was improved but with the wheel hubs sitting out on the axle (instead of the more modern practice of wheel hub locating in a bearing in the brake/steering knuckle) there seem to be axle flex as indicated under hard cornering when the axles flexed and the disc outer edge was rubbing on the calipers (yes the axle nuts where done up. Gormsby has a 3/4" torque wrench which is over 5’ long). EFIMira’s M100 Sirion front was about to be copied and M100 drums put aft. The 100 pcd era was on the horizon. A parts collection began in readiness for suspension take two and it would not be suspension alone that ended up being changed.

May 2013 M Gormsby met Frank E N’stien and the two of them created another set of lowered struts , albeit, a much more dodgy set. (And it was about that time or just before that Mr Gormsby met Mr and Mrs Evil(h/way).

Pls sir ,more!

I fixed the image on the last front shock pic for you