Somewhere along the way a couple of other Daihatsus were purchased for parts. Each bought in the morning and scrapped by lunch time. A G100 Charade of which only the gearbox, a bucket of bolts and rear drums (these needed later) were kept. Paid $100 and sold most of it on by lunch time. If fact it was pulled down in the yard of the guy it was purchased from, engine and a few bits sold on the spot to others and cash collected from an iron monger whom took away whatever was left. The other was a four door L200 for $250. It was only a few streets away from a friend’s business. Totally stripped by lunch time only the four doors and shell were left and were picked up for free by a local tilttray owner. Gormsby had spares! Should have taken pics but both were quite hurried detours. There would be more spares to come in similar fashions.

Last snipet of info for the weekend.

The fuel tank needed to come out in an attempt to fix the fuel sender and Gormsby was never really happy with the poor fitting exhaust. He had a ZXR1000R Ti muffler but as things were it would not fit. In a stroke of genius/stupidity (readers please select the word there that you see most fitting) he decided to route the exhaust straight though. So the tank was sectioned (it was fuel surging with anything less the 5 liters), baffles installed and now down to a capacity of 20 liters it provided a straight line to the tire well. Well the well had to go.

That looks nice! been planning to delete my tyre well and run a centre exhaust also

Have a look at this haha, a guy in New Zealand who is building a mega camber / stance L700.

He had to relocate the fuel tank to the back to get low enough.

Concerning the negative camber overkill on that Cuore “I feel ill”. Anti-performance and “just playing dress up”. Some people are incapable of making pragmatic decisions and far from having any understanding of the things they see and attempt to copy. To all the Stance people out there “you still need more - it’s no cool until you hit minus 90 deg camber”.

Hahah that’s awesome @WoodWorx!

The L200 had already been lowered and the control arm inner pivot on the K frame was sitting at the same height as the pivot center of the ball joint to reduce the car’s height. Going any lower would reduce negative camber with bump, dive and the outer wheel while cornering. So the inner pivots needed to be raised. Well if you are moving stuff like this it is best to see what else can be achieved at the same time. So the engine mounts were all moved back 20mm. This was done by moving the K frame up and solid mounting it against the chassis.

The rubber locators as seen in the picture were latter linished down even further. In the end they only helped locate the frame and its connection became steel on steel. It was raised 12mm. To bring the engine back down some polyethylene spacers were made for the center k frame brace (which has the integral rear engine mount). These went below the K frame to push the middle section down and its holes elongated towards the rear by 20mm (this also ensured the sump had clearance). It was found that a Siron front engine mount helped in lowering and pushing the engine down and back just enough with some minimal elongation of holes. A new gearbox mount was made by chopping the old one and sitting the cylinder right on top of the K frame. The gearbox’s lower most bolt for the 5th gear cast alu cover fouled on the K frame. Images shows the offending section during a test fit.

This was machined such that a shorter bolt could be fitted. With the casting short the fit is perfect. If the K frame had a thicker section it might have been an option to notch it but it’s the thinnest section. Plus the steel bracket that come off the end of the gearbox also needs to be reworked to clear (latter a new solid rubber bush was pushed in to negate the use of Sikaflex as a stiffening solution)

EFIMira was having some issues with his turbo EJ-DE midnight blue L200 damaging gearboxes and devouring drive shafts. The TRXX box with viscous LSD that he had been using was purchased and this with M100 hubs, struts, brakes and so forth were also added.

Note that the viscous unit sits outside of the gearbox and is not located in the diff (the cylinder on the right in the picture).

The diff also works as a jack shaft. The benefit is that the car ends up with equal length drive shafts. Having one long shaft means it can twist more so than the short one under power and when it releases its stored energy you get a torque steer effect.

A dummy shaft was made up to gauge the correct length. Then a big rummage through a heap of shafts found something close. A bit of simple machine work to one end and a problem solve with the CV joint for one small fit issue and presto a non-welded drive side short shaft.

Some new really short Koni reds were found sitting on the shelf of a friend’s suspension buisness and he suggested pulling the internals out and placing them inside a set of shortened M100 struts. Seen in one of the pics is a std M100 strut next to a shortened leg, and then the Koni internals that get slipped inside are shown. And finally an image of how the tube is extended below the hub bracket thus keeping the bump travel high but not so high that it hits anything at max travel (okay a bit of rub with full steering lock). The ride height was played around with an awful lot. Lower “yes” but stupid low “no”. The car would be used on a lot of Gold Coast Hinterland back roads. There was no point ending up with such little wheel travel that it was going to run out of suspension travel mid corner. Slam and Stance people note - your cars are dangerous, slow and, to old farts like Gormsby, they look stupid sitting on the ground (if ultra low is cool then it’s time to go the next step and start burying cars)

Here we have the ef-el gracing the L200 for the last time. It shows std exhaust manifold had been reverted to as the custom headers kept cracking. Some HID lights were added before things were further pulled apart.

Two last pics of the struts. It took a bit of time to get the spring seat in the right place. Measure, measure, measure - springs in springs out - sit it on jacks with wheels on and no springs - tack weld seats on and install springs, check height and…presto finally you get it right and can weld all up, paint and install the wet insert.

So when you say the k frame is hard mounted, do you mean its bolted up hard against the chassis rails?

Refer first picture in the last reply shows the nut up against a big washer and a conical rubber.

Yes bolted. The crush tube must be shortened and rear bolts were also shortened. Will shorten the front thread one day. This has been improved upon again recently by tack welding new crush type tubes directly to the K frame while in the car, removed and welded properly. Centering the frame before tack welding was done with great care and repeated measuring. Now the solid bolt connection does not require the rubbers to center it and one can only assume the whole front is stiffer.

One of Gormsby’s friends has just jogged that old man’s memory and reminded him that the front suspension and gearbox went back in with the EF-EL for a little while before the EJ-DE went in. The M100 front rotor and disc and rear M100 drum and wheel cylinders made tremendous improvement in stopping power.

New 100pcd wheels kept it looking understated and did not seem to attract much attention (Okay this last pic is out of chronological order. It does not show an M100 drum so much as hinting at things to come soon).

At this time quite a few Daihatsu owners would ask what parts were needed and how was an M100 suspension conversion for an L200 done (same would be asked about the disc brakes for the rear). The information people wanted was concerning what control arm to use and what to do about drive shaft length. EFIMira steered Gormsby towards the answers for that and information about the disc rear was given reciprocally. On occasion when the answer to the mystery was given the new recipient of the pearls of information what ask where they could get the parts or if the giver of the information would procure the bits for them or perhaps even do the conversion for pretty much free. It was not uncommon to find people unwilling or incapable of doing fairly simple investigation work.

Some readers will now know what front control arm to use. Yes it is a Daihatsu part and is found in LXXXs. So that narrows down which models to look under (of course it also rules out original L200 bits so really narrow parameters). When it comes to drive shafts…you have to figure that bit out for yourself.

The viscous LSD worked a treat even with the car’s asthmatic power. One could drive over really uneven ground without worry of getting stuck. Plus at full tilt in low speed corners it no longer smoked the inner tire. Instead one would get a little spin and a split second after the spin would be progressively limited and the thing would thrust forward (okay lurch forward rather than what seemed to be just sitting there).

Note the calliper bracket is pretty much a flat plate. Gormsby did make another set from raw material. The centre was turned in a lathe but there is probably no reason why this could not be made with hacksaw, files and drill press.

Just found a picture of the adaptor for std L200 brake cable to fit up to an Applause calliper.

So what was next? Gormsby ends up unwell and has bowel surgery and carpel tunnel fixed in both hands.

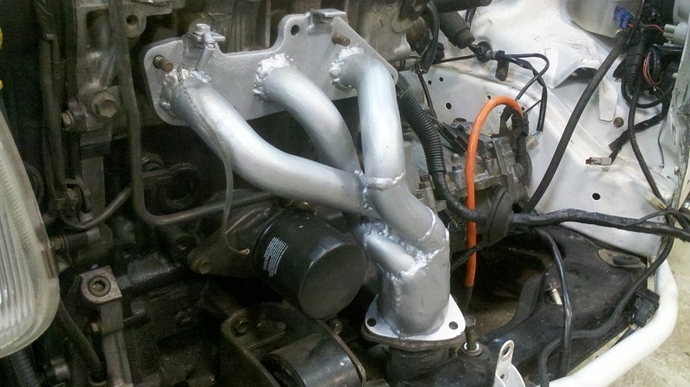

While out of action and not able to move close friend EFIMira made a couple of “Cheer up old Gormsby visits”. It was very cheerful since he bought with him a really low K EJ-DE and popped it in the Mira with an extra light flywheel and the next day he persuaded Michael (owner of the Red TRXX with all the bolt ons body bits) to come over and wire it up. With all hooked up (except for the exhaust) and running (loudly) Gormsby was ever so excited but virtually bed ridden. Then one day when no one was around to make sure he was resting he shuffled downstairs to investigate hooking up the exhaust. With stitches just out of one hand, the stitches out of the other the week before, limited tubing, an exhaust manifold, a spare steel inlet manifold and subaru exhaust flange for collector base and with existing exhaust section to match to, he shuffled around the flow for the day (on his butt) to reconfigure an inlet manifold into an exhaust.

Primary lengths ended up close to equal. The 120deg firing separation means that there is no pulse tuning benefit to things being equal. Things ended up as can be seen simply because the primaries used every millimeter of the donor inlet manifold, there was no straight tubing of the same ID in the workshop and Gormsby was not suppose to be driving anywhere, yet let alone working on the car. It was a bit noisy (tinny) but a thorough fiberglass wrap (using left overs from a friend’s R33 GTR build) seemed to help there a little. It would be still anther couple of weeks before he could venture out. Then, other than a short test drive the first journey would be off to the dyno to get a baseline reading. First driving impression was that it had two if not three times the power and torque of the EF-EL.

i love reading your thread

Thank you Mr G.

I have to agree with these guys the amount of work that has been put into this is amazing and thank you for sharing it with us and I know this isn’t even half of it .

Gormsby’s memory is a bit fuzzy on when it happened but it was early on that he did something about the awful driving position as well as making up some delrin bushes for the gearxbox side of the shifter cables which in turn led to doing a quick shift also (doing the same for Doonster whom said thanks by putting LEDs everywhere in Gormsby’s car except indicators and headlights [Araon was asked to take the red ones out of the dash and put something brighter in]).

No pics just yet of this, rather here’s a, perhaps, long winded insight as to where/how ol’ Gormsby gained enough desire, experience, knowledge and most importantly understanding to problem solve all of the stuff written herein. If you can read between the lines you might pick up on why he abhors show cars, dressed up cars, stance non-sense and show ponies (all of you that fit that bill can abhor Gormsby back he’s okay with that). Performance is key here and aside from the show that sponsored people need to put on Gormsby ascribes to Sun Tzu idea he conveyed in his book “The Art of War” which can be paraphrased as such - when your army is week pretend to be mighty and scare off your opposition but when you are strong hide the fact and let your opponent be cocky such that they are easily overthrown.

Back as a kid Mr Gormsby Snr was in to cars quite a bit and would take the wee Gormsby to Lakeside and Surfers Paradise International Raceway for the big races. His parents had a dune buggy (Manx body VW with warmed 1600cc that Gormsby learnt to drive in when he was eight years old and would drive around trails that criss-crossed the ten acres up the back yard. It was the 70’s and giving the car to the kid for a few hours on his own was cheap amusement and something Gormsby appreciated so much that it added to the reasons for which he paid his parents so much respect), LC and LJ GTR XU-1s (when they were new), fast minis (in which he picked up left foot braking without even knowing he was doing so, “I found it just makes the thing turn in better”) and even his Unlces and Aunties had stove hot Torana’s and Monaros (except for one uncle whom had a series one Honda Civic but always talked of wanting an Alfa). School days were spent dreaming cars and there was nothing better than helping Dad tune triple carbs on the weekend. Finishing high school he took up karting on oil soaked dirt tracks for a year while repairing and refinishing semi-trailers (Spray Painter apprenticeship). Everyone at work was into fast cars and motorbikes - except for the uncle with the Honda who also happened to work there. He got to help build some show trucks, latter some concourse sports cars, help with sign writing on top door slammer and rail drag cars - this was a bit pretentious for Gormsby as he had a pragmatic streak and hated seeing cars as static displays - what was the point of all the hours he put into something just have have it gaulked at? Although he was exposed to heaps of fast cars including doing paint work on Ron Wanless’ new XC Falcon hardtop touring car the car that had the biggest impression upon him was Kevin’s Datsun 1600 whom lived two doors up the street. Not just any Datsun it was a top state championship no expense spared rally car. He also had a circuit type XU-1 with triple webers and so on, but the rally car was extreme and exciting. Suffice to say young Mortimer Gormsby’s first car was a 1968 Datsun 1600 that would end up with a full roll cage, L20B with twin webers, LSD diff, big four wheel disc brakes and more. While he never did a proper rally there was the occasional motokhana, khanacross, rally sprints, track days and a ridiculous short course off road race he did. The rallying interest found him as service crew for an outright contender (Murray Coote beat us in his "Ground Effects Datsun 1200 for the state title and it came down the last stage of the last rally of the year) and he traveled to many state, national and eventually to the WRC to support top Qld competitors who had cars that included Grp G Datsun 1600s, a Grp G Rx7, a Grp N Suzuki Swift, Group A Mazada Familia, Grp A Nissan Silvia, a PRC 280z (like a 240z but with the homologated 2800cc efi), even a club rally 180B four door with an NA 180hp L series and did a chassis rebuild of a class five national championship winning off roader. From these experiences he found himself working for a small company working on sports cars, selling parts for classic sports cars, preparing rally and serious club race cars and supporting customers at race events. Weekends were full of motorsport. One weekend he might be in the pits crewing for a Group A Corrolla amidst the likes of Brock and Johnson, the next with an Appendix J event helping with a Mini Cooper S and the next at a hillclimb Championship winning Datsun 1600 (which he still helps maintain/modify to this day and pictures from 2016 below). Gormsby had cars at this time that ranged from a 1978 Ford Transit to a Porsche 914 to a Subaru Vortex to a hi comp, big cammed A15 Efi (Haltech) powered Datsun 1200 2dr 600kg dry with a works Opt 1 cr 5spd, 300zx koni coil over front struts and brakes, works LSD, rear discs, reverse rebound rear leafs on top of the front of the rear leafs to turn the front section into trailing arms and a long lateral link. It was run in Khanacrosses with used Avon slicks from the Formula Series at the time and it won a couple of events outright.

Between those days and now there were years in science laboratories as a tech guy, some uni years with study that included mechanical engineering, “the Arts” (with a focus on the Psychology of the Built Environment), and post graduate study in Education. In those years motorsport gave way to racing road bicycles and he would sometimes win the local club A grade crit, won the occasional championship and toyed with the big boys by doing a few National events and several trips to North America and once to Venezuela. All the while there was on going involvement in making that one Datsun 1600 go faster and a progressive interest Subarus after working as service crew for George Kahler (group N Mazda Familia) in the 1989 Rally Austalia and working often next to Possoum Bourne’s team and interacting with the guys a bit (to this day one his dream cars would be an ex Vatenan or McRae RS Turbo Legacy). This was nearly as inspirational as the effect that Kevin’s Datsun 1600 had had on Gormsby back in the really early 1970s.

Not the rally car that inspired him as a kid but the Datsun which Gormsby has played a small part in its development since the late 1980s

March 2017 it took the class recored, again, at Mt Cotton Hillclimb. More than a club race car it’s been the most “lateral thinking” and “think out side the square” engineering experience Gormsby has had the privilege of being involved in. In short, what you read and see of Gormsby’s L200 is the result of knowledge and help shared between friends with much taking of constructive critisism, of learning how to develop cars from first principles (ie not buying things off the shelf and bolting on haphazardly), a closed loop of trial-error-trial-error-trial and a passion to put performance above image and romanticism of cars.

So we come right back to driving position and the gear shift. What do you do when something like this is not right? The pictures to come might give some insight - yes pictures can say a thousand words. With the seats one could go out and spend $1000s on seats and Gormsby did that with his 1200 2dr but then had no cash for good tires. Tires are always a better go-fast investment than seats if one has limited cash (mind you 7kg for the pair of seats in that car did have some performance gain). The L200 seats were stripped of the fabric and squabs sculptured with a kitchen electric bred knife, the backs had 4mm steel bar bent up and migged onto the sides of the steel frame on each seat to hold foam side bolstering and lambswool covers thrown over top. The passenger seat was completed first and then those thing learned used to make the driver’s seat a further improvement. Ala, Faux pas Recaros. 25mm Aluminum spacers were made up to lower the steering wheel. The steering column was removed, the steering shaft had the splined end removed and swapped for a longer one from a Brumby (Gormsby happened to have such on the shelf as well as a MOMO steering wheel boss to suit and a 90mm dish wheel). The shafts were also line bored with a extra long series 5mm drill. No point really other than to take a tiny amount of weight out and to verify that the lathe’s tailstock was correctly aligned. With seats lowered the top of the steering wheel was well above the height of the base of anyone’s skull as they sat in the driver’s seat which is way to high. The wheel came down and rearward, yay. Gormsby had his preferred NASCAResque close to the wheel position and plenty of room to stretch his long legs. But now the gearstick was a big reach away. If you have to bend it back why not change the pivot ratio at the same time? During the mock up it seemed that there would end up being a long reach down to find the knob even though the wheel had been lowered. So the gearstick was lengthened such that the reach to it from the steering wheel was the shortest distance possible and the pivot ratio altered for the right balance of being able to find a gear and yet have a fast shift. It looked long and out of place as though the stick had come from a semi-trailer, but dang it worked a treat. No off the shelf parts needed unless you call mig wire, argoshield gas and some scrap steel off the shelf (plus an engine lathe to machine the bushes). Did the end result look pretty? Probably not and Gormsby did not give a rats’. Did these things make the car faster and more fun to drive? You betcha!

That is an awesome read and insight. Thankyou!

Going disc on the rear happened either 2013 or 2014. EFIMira had picked up an F2 Charade and a quick check revealed the rear discs and calipers would easily fit. But alas the rotors were uncommon and a new pair were $600. Some Appluase rear calipers, discs and mounting brackets were found. The brackets required the center holes to be bored out so they could be mounted on the L200 control arms. Measurements were taken and some thought was made about CNCing them out of alu. But the prudent route was to invest minimal time and make sure the set up worked.

Mira appluase disk bracket2.pdf (15.4 KB)

Later it would be decided that the caliper piston diameter were to small and the watch for something better ensued (for the rear, larger rear pistons can be found using Mazda MX5 rear calipers that seem to be an identical casting to the Applause ones. Can’t remember how much bigger but somewhere between 2-4mm larger piston diameter).

To get the discs to sit on a 100pcd hub the rear set of Charade drums which were sitting on the shelf had the drums machined off so that they would become the disc carrier. This could have been done with the M100 drums but they were destined for someone else’s 100pcd rear conversion. Track width increased 20mm total with all fitted and the calipers had to be spaced out the thickness of the Charade hubs. For the first trial the calipers were mounted upside down to make the handbrake cable easy to attach. The brakes were easily bled by opening the Banjo bolts.

Some steel tube was made up to slip over the handbrake cable end and such mounted to the caliper handbrake bracket. For EFIMira the tubes were done in aluminium and the calipers mounted right way up after a simple cable re-route along the top of the trailing arms.

Gormsby was never happy with now having four flexible brake lines on the rear and would, finally, in 2017 flip the calipers make new hard lines and halve the number of flex rubber lines.

The brakes were definitely more powerful. The master cylinder and rear bias valve had not been touched. EFIMira with the 15" Enkeis was able to go one better with brakes by fitting Copen calipers and rotors.

His brakes were now more in keeping with the near on 180hp. And so was the M100 gearbox he and Gormsby fitted to the dark blue L200.

Loving your thread mate!

Good to see the super secret mira in there too!

EFIMira in it’s 110pcd heyday

To those that don’t know EFIMira and it’s creator it/he was ahead of its/his time. Some may remember that the car was pretty much written off in a strange and disappointing way (no one was driving it).

Note Dan or Jono’s old bumper sitting at the front.

So the Blue L200 had to be reshelled (more images of the process somewhere but I’d have to dig)

The resting place of the old one was Gormsby’s front yard and there it sat for a couple of years. But an much less damaged L200 shell came along and it too had some notoriety in its better years.

The driveway needed widening so he got out his most expensive 3cyl (which is a great engine crane and is balanced just enough to life items as large as Sirion shells onto car trailers).

so out with the blue mira to make room to turn around and into the back yard with the red one.

The Gormsby L200 Dec 2014 just to bring the focus back to it.