Awesome info Mr G I have never done the deadener removal and knew it involved dry ice but was unsure of the technique. I have been around dry ice once or twice and understand the gas and not to touch. I am really glad you added those in for people who didnt know the danger’s

What - Daihatsu actually uses sound deadener?

I have never lifted the carpets on my G102 - never thought there would be anything to see from the amount of road noise I get!

From my understanding of acoustics, the deadener alone will not stop noise. To do that it would need to be continuous with no gaps. The floor will have gaps and holes, these will let sound through. Deadner is a quick and cheap way to cover an holes. Then it also helps to the thin metal to attenuate noise. Sort of changes the frequency of noise to make things sound less tin like.

I’ve had perhaps ten L200s (six of those were just to wreck), a couple of Sirions and one Charade. All had deadener.

I did not weigh the media that came out, but I would estimate 7kg in the Mira. My Series One Liberty/Legacy wagon had just over 15kg of deadener and 10kg of carpet underlay.

Wow, how time passes. What has happened here? Or perhaps you might ask why is nothing happening? With the next annual track/sprint/race weekend for Gormsby’s regional LivetoDai group being Sunday coming it is another missed opportunity to have the L200 going. On the one hand Gormsby may have gone to far with “the build”. That is something to consider with modifying a car. Are you better off getting huge amounts of seat time or will you spend more time with the thing apart seeking to make it go better? Well Gormsby has another car for competition and he has been competing on a monthly basis, so he is getting seat time. What about the Mira? Well, with another car to “race” the Mira was relegated to storage. Part of this is due to time, some due to lack of working space and some due to loathing the predominantly electrical work that needs to be brought up to a level of the rest of the car. Gormsby has said the car has little meaning to him when it comes to the thought of needing to be seen in it or wanting to be part of the Dai social culture. His fit in DaiLife has perhaps been more about pushing the boundaries of what can be gotten out of a Dai. And for this at times he may come across as brash. The L200 is to him not cute, not trendy, not good looking and certainly not a collectible classic. On the contrary he has said it was a badly performing car, a low cost utilitarian vehicle (but not “cheap” as in it does have those fantastic manufacturing qualities one expects from a Japanese product) and something that is a real challenge to make it into anything worth driving let alone racing. As J Peterson might say “I risk saying such things despite the possibility of offending others as I am interested in the pursuit of truth”. So before this gets too deep and unwieldy, this “gone to far” build should be coming back “on track” (ha ha) soon. But the Mira will come back to life in pursuit of solving problems as this provides Gormsby with intrinsic motivation and perceived freedom, or as John Neulinger would say “optimal leisure”. The major problems solved so far: handling - adjustable dampers fitted, spring rates sorted, front bearing issues sorted (toss ef and install M100 type) and decent tires catered for; driving position - column location changed, pedals changed, huge bolsters added to seat and seat substantially lowered; power/torque improved - mild NA EJ-DE tripled the power and quadrupled the torque of the previous NA highly modified EF-EL and for the diverse gamut of club Motorsport it remains more drive-able than a turbo variant; traction issue - LSD fitted; the awful 3.9 turn lock to lock corrected for 1.5 turns l to l (you cannot seriously do motokhana, khanacross, hillclimb or any racing other than drags without such); and now it is time to bring proper electronics with full data logging and full solid state electronics. By the time it is going again it won’t look much different externally other than long 12 x 1.25 ARP wheelstuds and bigger rubber. The story, or this story, may start back up again and if it does it will need to take on new meaning for ol’ Gormsby to be interested enough to document anything. It is his story, his experience and his understandings. Hopefully, the “new” approach will include empirical real world testing to explain the “why” of things as opposed to the overwhelming “opinion” and “emotion” based stories on how to best build a race car (it will not be how to build a race car look alike).

I love the fact Gormsby has followed his own path and development of his L200. As he has stated it does not look anything special and cool, no stance maybe just a bit odd with round wheels arches and huge big wheels and rubber to 99%of the population but not to the ones that have been shown or can see what has been done. Having Gormsby let me drive the car before the lock to lock mods and a lot of other’s. I was more than impressed oh how much power and torque the NA EJDE had and then when I had a ride as a passenger I developed White knuckle fever and almost lumpy pants.

It was a few years again until I saw Gormsby’s little monster at a motorkahana day. Wow did it perform well with the inside rear wheel lifting right up high like a fly taking off before you swat him with a newspaper but still so stable on 3 legs. Sure it wasn’t a perfect run for the day but that is motor sport, either way the smile on Mr G’s face said it all. One thing I do know is it may take Mr G a while yet to get through the wiring and other challenges ahead but when they have all been overcome Im sure I will see that smile again and look forward to the day i do.

A few random images to make up for the dearth of visuals

(upload://b03VxjjYj9lkgbkbFBGvO76EKOl.jpeg) ![efimira%20(1)|666x500]

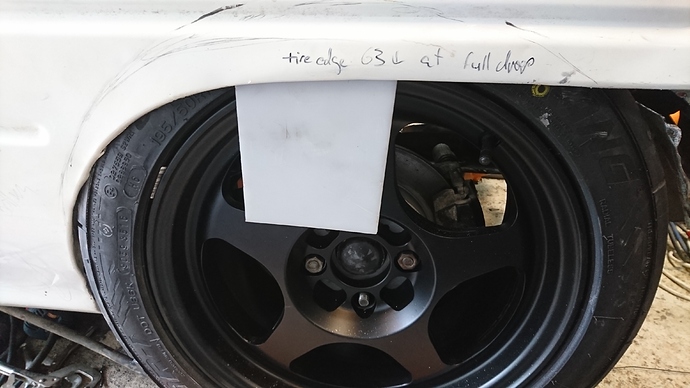

A bit of cutting away for the big tires and how to maintain full travel while being able to do some extreme lowering to make up for the tall wheels. The outer skin was separated from everything such taht it could be pushed out 75mm. Wheel arches were cut out and the edge raised as it looked as though it had been “slammed”. Raising the wheel arches makes it look less like it has been tampered with and hopefully on the street it will attract no attention.

(upload://bWmujOdCBLj1KSq87fccZeW2fhU.jpeg)

Pic with the rear tubs done prior to the front being pumped out. On small wheels for the last time. Rear arch ishould end up lowered 50-75mm and the front arch raised for visual balance.

Just like the above, some of these could be repeats

The biggest tire being catered for here is an 15 x 8" with a 225/50/15

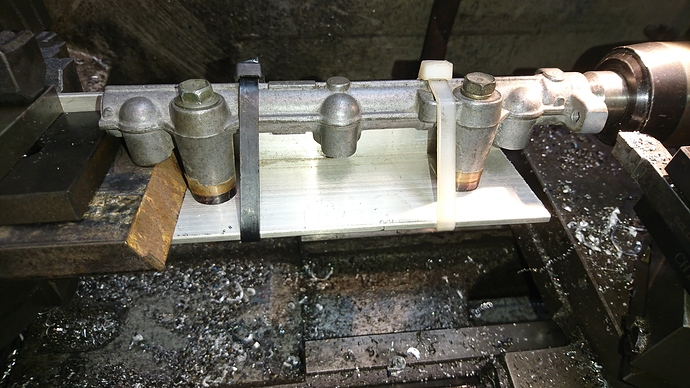

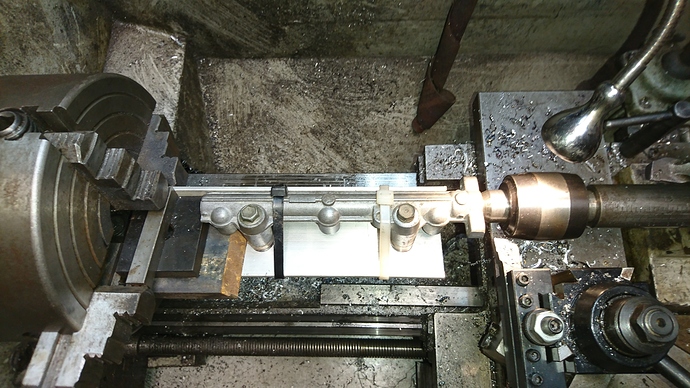

(upload://cytKySjJmcLVNsRPmi0ayDELxIs.jpeg) ! Got a bit lazy and made my threads for these adjustable spring seats a bit fine. Should have been patient and done acme or butress threads.

sony%20jan%202017%20118%20-%20Copy%20-%20Copy%20-%20Copy|281x500 !

sony%20jan%202017%20119%20-%20Copy%20-%20Copy%20-%20Copy|690x388 Vertical damper rather than inclined made a noticeable difference. One can make adjustments that the mind is able to figure out. With the inclined damper the rate change always meant a compromise setting since the damping curve is not linear with the std inclined damper/shock position.

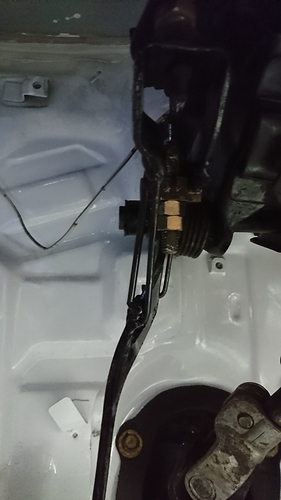

This is the custom part needed to make the L200 factory handbrake cable hook up to an Appluase calliper if using all original disc brackets.

Is all the stuffing around worth it? Here an ej-de fuel rail is bored OS and then the end tapped for a threaded fitting. Discovered that top mount Subaru injectors fit. Can put my smaller discarded injectors from ej20 and ej25 to use.

The fourth image is perhaps confusing. It shows a steering column lengthed 100mm. The internals are from a different Japanese car and nothing is welded. Please do not ask how to do this or what parts are used, Gormsby has simply said “I’ve forgotten” and much of that is truth since it was done years ago. First image is of a hybrid universal configuration. Knuckles are changed to adapt to non-std splines. Note the big brake pedal. Second pic shows a reinforced clucth pedal. Not really necessary with the set up in the car, just future proofing it. Third image shows the alu stand offs that are used to lower the column to the preffered height (std seats are used but quite modified with much bolstering, factory fabric removed and lambswool covers tossed over, and seat height lowered muchly and squab tilted back.

![10_4_17%20554|374x210]

![10_4_17%20554|374x210]Big hole (upload://ffeYYUi9iuFHlNTFAisHimRoEKi.jpeg) Final pic here is pre-modified wheel fitment with the small 195s. Final iteration will sit lower and regain full wheel travel.

Just how far out does a 225/50/15 sit when on a 15 x 8"?

oh I love this car Mr G so much done and so well done!

You sir, if in town when it is going and there is a Khancross or Motokhana, you can go dual entry with me. I promise. Not just because of your kind words either. More out of respect for what you’ve done for the community worldwide and since your friendship means an awful lot - you’ve been better than most of my family.

How can i say no mate. Thankyou. It will be my honour!

wow your shed is so clean  . Makes me feel the need to clean up mine lol

. Makes me feel the need to clean up mine lol

Oh the wheels on the mira look really good and suit it. well done.

First bit of progress in quite a while. Lots of bits procured for the Mira. Gormsby has just been throwing things in through an open window and letting all pile up. A top of the pile, long ARP wheel studs and wheel nuts with 17mm head (just a note here on aluminum wheel nuts - at the worst time they will gall out and not come off or on). So they replace the Subaru ones I’d been using. Factory are M12 x 1.5 and require about 120nm to tighen vs 90nm for the M12 x 1.25. In comp I’ve had correctly torqued wheel nuts come loose in Khanacross on rough bitumen. The finer thread are less likely to come loose in my experience, even with the lower torque. The 17mm are a bit lighter than factory and the socket suits these wheels perfectly). The one pic of the wheel installed shows things spaced out 15mm, which I hope not to have to do with these wheels as it impacts the scrub radius to much. Hmm, what to do next? Maybe trailing arms bushes as I see some bits for that on the dash and I’ve already punched the rubber ones out of the trailing arms (bolts but no bush holding things in place).

So what is the reasoning behind longer studs Mr G?

Rims are a bit thicker than previous and nuts are longer than I was using. As such it looked silly with three full threads not engaged showing at the end of the open wheel nut. On top of that I could not use my 3 or 5mm wheel spacers.

I need to do something simlar with the move also. I use capped nuts at the moment and while they still work fine It would be better if there was a thread or 2 more on them . It is a small down side of rear applause discs.