A huge big up to my team; dunno how I would’ve gotten through the weekend without them

I’d stick with the L700 box or an M100 one (same but diff diff ratio). EFIMira’s box problems all went away with such a swap. Prior to that the 150fwhp keep eating gearbox bits.

Yay, go team! I am mostly a team of one at events.

Ya, this is the box I want to use, just that I was hoping to pull it and make a check if “that diff” could work in it.

I can work on my car, but I really don’t like pulling it down  .

.

This is the first I’ve actually had a team to support me. Usually me alone. Takes a good load off the shoulders

Hail all

Want some input. The throw if the shifts in the l700 gearbox is good; but I’d like to raise the height of the shifter without increasing the throw.

Any recommendations?

A lil sketch will help too

I am really busy this week, but will see if I can remember to do a couple of sketches. There are a couple of L700 linkages down stairs so I’ll have to look and figure out how things might foul with the floor.

I have really long gearsticks in all my cars. I am often told how uncool that is (my students esp). To me it’s not cool to move my hand 500mm to hunt and search for a knob [no pun intended], If the stick is right near my hand on the wheel then I’ll have more control. Is this your kind of rationale? I recommend a prototype in timber to get the pivot height, total length and throws correct.

Three options.

First. is a really really long lever and the pivot point raised right up. Which is what I’ve done with the Subaru (Oh, I bought a WRX MY02 last weekend, completly std never modified in anyway save for tinted windows).

Second, would be to remote mount. This would be to raise the whole thing up and run a dog leg in the stick to gearbox selector shaft.

Third - combine one and two.

Mr. G, you know we both have the same principle of function over style. Yup, want it closer for better control.

I was also thinking of increasing the steering wheel diameter. Bigger diameter would mean less turning; wont be like a quick rack but should make a difference.

Right now I’m trying to focus on getting those tires in time for the october meet. Installing a Aermotive fuel pump and 550cc injectors.

My fabricator was thinking of raising the pivot point but I think that involved modifying the body of the car  . That’s one thing we try to stay away from

. That’s one thing we try to stay away from

Thank for the recommendations

Big wheel = no difference really

Roger that @Mr_Gormsby.

I happened to take in that series “Seven Periods with Mr. GROMSBY” you couldn’t have chosen a better alias

. You’ve got the character good and proper

. You’ve got the character good and proper

If you watch all 14 episodes it all interweaves brilliantly. It becomes all that much more real being a teacher myself. So much of it is not far from reality.

Yup watched both seasons. Feel imma watch em again

UPDATE:

Since I had this car resprayed early 2017, the front fenders were to be flared. Didn’t come out the way I wanted. So I contracted a well known fiberglass guy who does work on many race cars in my country.

Handed him the fenders to make the mold and downpayment and for over 3months it was a cat and mouse game

.

.

FINALLY he’s come around and has started the work. What I want is for the wheels to have good clearance to ride into the arch and ofcourse it fi look good.

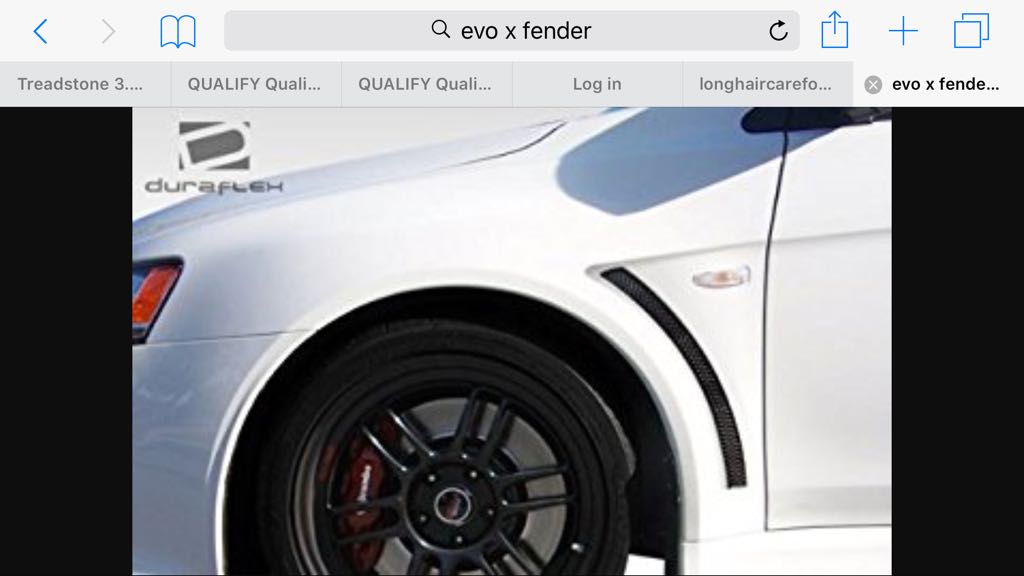

The design is going to incorporate a vent to the back of the fender. Evo has it for aided brake cooling; but for that to happen air has to come to the brakes right  . Well this might just work out more for looks than function then.

. Well this might just work out more for looks than function then.

This is the vent we going for

Next week he’s to come back and finish up.

Sadly my fenders from my other L500 which I repainted a year ago were damaged in the molding process

.

.

I just want to get this over with

Wow those custom guards… Why not just cut the guard and run flares? Obviously that won’t be as pretty as your custom guard but I would hate to have it looking so good then find a tyre wall… Hahahha

I’ve done a fair bit of this. Back in the late 80’s I built plugs and molds for truck fuel scoops and some part like you are seeking to do. I still do them a bit. The first pic is from about four years ago, and the second, is from last year when we repainted the car and I redid the flares from scratch since the rears were not quite the shape we wanted, plus we had to find another 50mm of wheel travel.

I’ve done sports sedans too (could show pics). Any way the point is that I’ve done what you are up to a bit. To have damaged your old guards I can only imagine no polyvinyl alcohol was used. Perhaps just wax. And I would have made the molds two part, just as I did for the Datsun. If you have any quesions please ask. I am only using glass for molds and carbon fiber, kevlar or basalt for final parts (okay glass for protypes). If you are buying cloth product locally (I hope they are not just using chopped strand as you parts will be weak and heavy) I’d look into prices and product here http://www.sollercomposites.com/NewSoller/index.html. They are the best value for money product I’ve found world wide.

Oh, the vent in the back of the Evo is not primarily for brake cooling. Main reason is to release pressure build up from under the guards to kill lift. This helps brake and engine cooling too.

@Daiharris, if the fiber is fender is to be damaged i not have the mold to just build another  . I was so frustrated when the original fenders weren’t done right; i was going to go the route of buying flares but couldn’t be advised as to what size to purchase AND I couldn’t find any right side stock fenders locally.

. I was so frustrated when the original fenders weren’t done right; i was going to go the route of buying flares but couldn’t be advised as to what size to purchase AND I couldn’t find any right side stock fenders locally.

@Mr_Gormsby, as frutrating as the wait has been, he seems to do quality work. The fender is light. He has the fiber as a sheet of cloth, so when he was doing the fenders themself, I saw him cut bout two sheets and layer them. As to the polyvinyl, i did see him use a lil green chemical of some sort but it doesn’t seem he has much so he’s using little little of it.

I’ll keep u all posted on how it turns out. Thanks for looking out guys.

Guess i’ll be doing a little fiber work soon @Mr_Gormsby

Yeah this is true… Well hopefully it turns out well, it defintely looks good in theory so hopefully you dont meet the tyre wall anytime soon!

We actutally have no tire walls…we have a gullys and concrete walls; none of which I’m going to get intimate with

Here’s a vid recently uploaded of race 1 of the October meet. It’s great to get a chance to see from the outside.

This is the street class; due to the number of entrants, the turbo charged and natural aspirated classes are put together and everybody is gridded according to their qualifying time.

Just got in, surprised to see the fiberwork is almost complete.

A huge thanks to my friend Kamar for transporting the workman to and from my home as I’m at work between 8am-10pm for the week. So he’s also supervising the work being done

for the scoop, I’ve decided to do a reverse scoop set up. Hope it works out

Fuck that track looks awesome man, it’s good seeing a big difference in all the cars on track… Thanks for the facey add the other day as well, I’ll be spamming you on messenger in no time hahaha

The guards actually look good, tbh I was a bit sceptical about them but they actually look quite good… Lots more room for tyre under there now though… Get those AR-1s happening!