Ok man

Will post as everything is done and set

Ok man

Will post as everything is done and set

It’s almost 2 in the morning here in Jamaica; just drove in from work (made a stop o the way) and i was greeted with these

. Im my culture we’d say “mi gladbag buss ya now” meaning “I’m really happy”

. Im my culture we’d say “mi gladbag buss ya now” meaning “I’m really happy”

I’ll have these sleep right beside me tonight

So finally, I got the main parts I’ve wanted to install on the car before the October meet. Still wasnt comfortable with the 12.2 ratios I saw on my wideband; from how the spark plugs read, seems I have a flow issue. So I bought the AEM 50-1200 pump. This pump is able to handle E85 (which is not available in my country); since our fuel has ethonal (E10) I still spent the lil extra and bought it.

There are three things I’m focusing on for installing this fuel pump.

Replace pump supply cap

My car was originally a carby and the carby inlet and return are smaller, so this may be causing some level of restriction in flow. I decided to link with my junk yard friend and he easily found and gave me a supply cap. Not sure which Daihatsu it came from but it fits the L500 tank.

Trap door to access fuel pump

Heck, why have I been torturing myself to pull down and fit up this fuel tank.

I will be finding something to seal the edges in the morning.

13.5V at the pump

Before I changed the pump, I did a voltage check to see if that was what was impacting on my low pump flow. I hooked up my voltmeter to the fuel pump circuit and did some pulls. The range was 12.4V -12.6V which is sufficient voltage for a pump.

Now these aftermarket pumps were sold to run between 9V-18V; but the flow they sell the pumps are for 13.5V. Now I’m getting 14.2V from alternator to battery and a steady 12.2-12.8 in my circuits with cooling fan running.

I’m planning to have my electrician try and do something so I can get this 13.5V to the pump, as I’m thinking the recommended operating voltage it.was sold for should help it live longer.

I welcome some input here

Also another question; I had moved my fuel filter close to the fuel tank as I didnt like how it was just slopping around in my engine bay. Is there any pro/con to this.

I personally think not, as the filter for some vehicles are actually in the tank itself.

I did do a test run after the pump change and got 10’s to BLANK, which means really rich and we’ve got good flow now. As much as the wideband give you a collective idea as to what’s happening in the engine and not what’s going on in each cylinder, u still get an idea of what’s going on.

Next is a set of 440cc injectors that I got and to install the resistor pack needed to run them. I so dislike installing extra hardware for components; its one more thing to worry about. I purposely didn’t install them as I wanted to pin point what the problem was

Also on the agenda is adjustable brake bias. I do hope to deal with this before the meet. Quite a lot of rain on the island with the passing of hurricanes. Thankfully no direct hits but rain still comes.

After much headache dealing with the fiberglass guy he finally “finished” them…ya…didn’t cut out the section for the side indicator; sadly didnt realise until I brought them in to be painted.

Unfortunately quite a lot of rain so after the prep work to spray the rain came. Not complaining; nothing happens before its time eh…

Here are some photos of the “finished” product

Another productive day for which I’m thankful.

Tires have been installed, and electrical work has been done to have stable voltage and current for the fuel pump.

My electrician decided to wire two relays in parallel; we went this route as the relays I’m using are made for a 30Amp circuit, but they somehow heat up a lot, which we didn’t like that,so to share the load, we used two relays.

Wired the relays close to the battery and ran 12 gauge wires. Same was done for the ground. Didn’t have much 12gauge wire left some we split the grounds, one to the battery and one to chasis.

Before the wiring I checked the voltage with the new pump in and it was 11.64V with no load, 11.4V with fan running. With the relays installed 13.8V constantly  .

.

Next to install in the resistor pack for the injectors to be installed.

Before

After

Tires

Just for comparison exactly what were the old tires you were using, esp treadwear number?

Sumitomo HTR 200, treadwear 380

Good progress this week; nearing goal completion for next race meet.

Resistor box installed. Current injectors are high impedace 312CC, stepping up to peak and hold (low impedance) 460CC. I tested the injectors and it just so happens only 3 working  . Called my friend he said he had them cleaned and test. Anyway, lucky I only have 3 cyliners. Can’t drive around with them, as they’re flooding the cylinders so will put them in when I link with the tuner

. Called my friend he said he had them cleaned and test. Anyway, lucky I only have 3 cyliners. Can’t drive around with them, as they’re flooding the cylinders so will put them in when I link with the tuner

Panels FINALLY sprayed. All that is left is to have the scoop and indicators installed. Really glad to have my L275, transported the panel easily

Test fit

Nice work man and the rooster is looking sooo good those panels are soo shiny!

Panels installed and car buffed. Left the rabbit hand man wet sanding in the night  . On my return home in the morning he was comfortably bouncing to his music and doing his polishing.

. On my return home in the morning he was comfortably bouncing to his music and doing his polishing.

That looks so good Denniston.

Thanks man, it’s all coming together. Now for tuning

Very nice mate!!! This thing is such a mad little rocket nugget

WOW that looks soooo good!

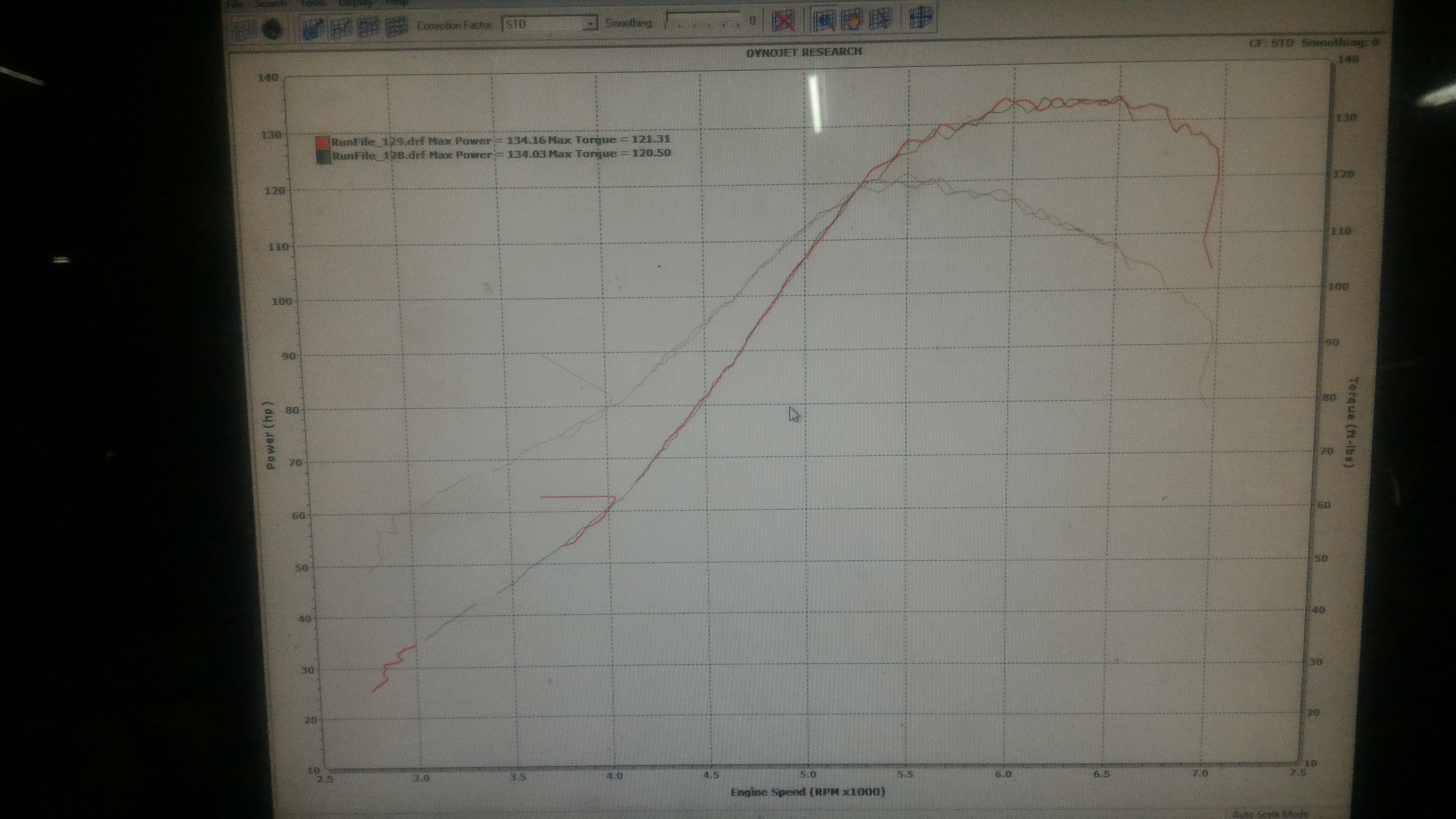

Well JUST got off the dyno. Made only 134 on 20psi. Not disappointed just want my ratios balanced. I know I’ve been beating this engine and turbo for couple years .

I ended up not using the 460cc injectors, yet another one started bitching.

On 20psi I used 80%duty cylce of the 312cc so that can live with as I only use 15psi on the circuit.

wow that is so good man you must be really happy.

Yup yup, really happy. Now for alignment and track day practice.

L275 got a set of rims. Wanted to go 15’s but a friend had a brand new set of 13’s for cheap and I already had some tires. Seeing that all my money is going towards this race weekend coming up

Think I should go 60 series or 70series 13’s on this???

Can’t use the 50’s too long, it lowers the car and the ride is so harsh

Small things can cause big problems. Fix em when you can. Noticed my alternator belt looked strange, i saw my race day gone cause of it flash before my eyes. Went out and got a replacement.

Also my front engine mount needed to be replaced.

Over 10yrs ago I tried this DIY windshield urethane things  . That’s 10yrs ago with a possible 10yrs old mount

. That’s 10yrs ago with a possible 10yrs old mount  .

.

There’s a company that rebuilds bushings. Apparently they use old tractor tire rubber, cut it and fit it. I didn’t even remember to tell them to do it as a solid mount, they cut the holes in em. No sweat, rear mount is solid.

Old alternator belt

old front mount

new mount

Good day all race day coming up. I must first give my thanks to all who gave input thus far from the LivetoDai family.

We had a track day October 8th and I was very impressed with the car. Instructor showed me some areas of the track I attacked wrong and also with better traction I was able to lower my lap time. Only having one issue; going into left turns the fuel seems to be leaving the pump.I’m using a L500 tank, have never had this issue before and I always race on quater tank of fuel.

My lap times have moved from a best of 1:46.45 to 1.44.45.

Now this class is a Bracket 45 class, so I’ll do my best to not break out in qualifying

FINALLY, I got myself a bucket seat, so no more rolling around.

We made our own bracket so the seat is in a fixed position. Unfortunately I didnt have my helmet at the time and so when I did put on my helmet we eneded up having to lower the back of the seat; this in turn cause my steering wheel to be too far. Sooo we extended the boss and I used a 1/2" spacer to lower the steering. Feels nice, just have to get used to the vibration from the seat to the helmet

2sec improvement is huge.