Wow has it been more than a year since i bought this car already? Since most of my little issues with the swap are now resolved, i think it’s time to bring this thread back from the dead and give you guys the writeup you deserve.

Let’s start from the beginning with some photos:

First time checking the car out with my missus, i thought the YRV would be considerably bigger compared to the Cuore. Also note all the leaked out ATF fluid under the car. The repair shop that was supposed to fix the trans but failed at it didn’t bother to put half of the oilpan bolts back in or fully tighten the other half. I could move the oilpan by hand up and down about 5mm!

After the purchase it was time to get the car to it’s new home. The rented towtruck was an unbelievable bag of bolts, the journey was an experience like no other to say the least.

We dumped it on a parking lot of a local supermarket where it sat for a couple weeks then towed it with my friend’s car near my house where it sat some more. Finally after gathering all the parts it was time to rob my poor mx-5 off of her home and put the car in my garage to start the work.

For perspective, here’s a picture of my driveway- downhill, then sharp right turn, over one high curb, over a second curb and finally more downhill to the garage. You can imagine i was quite worried doing this with a car stuck in neutral. You get one shot at it and there’s a looot of things that could go wrong with potential mangled bodyparts. In the end though everything went smoothly so i got to work immediately.

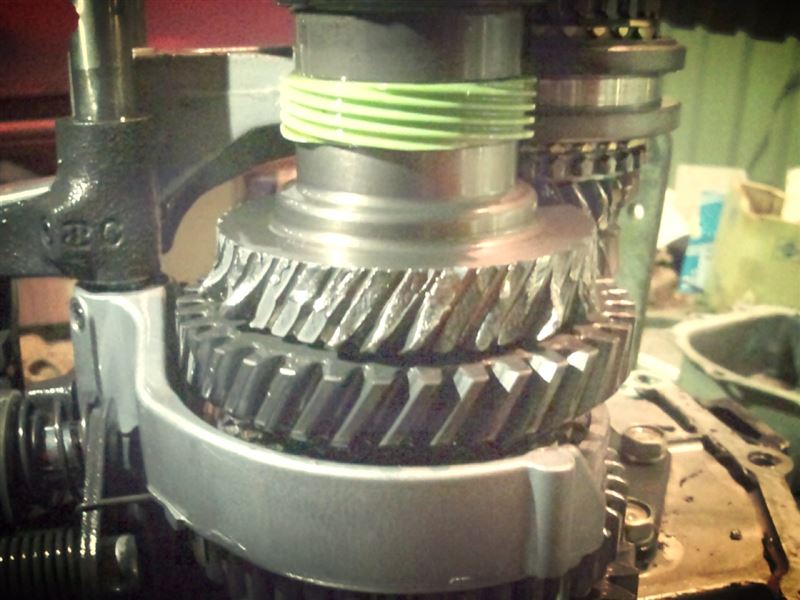

First off it was time to clean all the bits needed for the swap. A notable amount of degreaser, a wire brush and some elbow grease cleaned the manual transmission nicely. The shaft seals looked ok so i didn’t replace them.

If you’ve never tried Evaporust, i highly suggest you give it a try. The results speak for themselves.

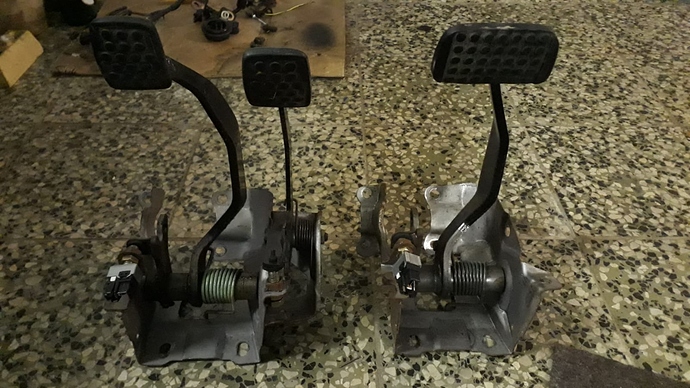

A little comparison of the auto vs manual brake pedal assembly. The manual unit bolted right up.

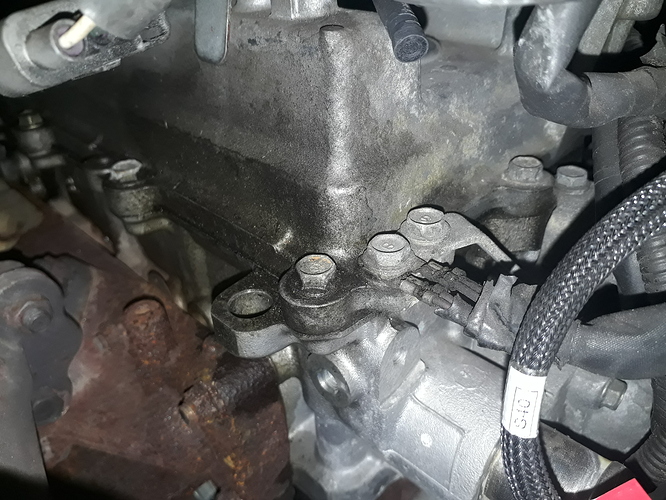

To my convenience the hole for the clutch cable in the firewall is present even on the auto chassis so it was just a question of routing the brand new cable through.

When disassembling i found the left side of the engine under the turbo covered heavily in oil. The reason for that turned out to be a cracked end of the inlet tube that was taped up with electrical tape. This fix obviously had no chance of working and the oil coming from the breather tube happily seeped through.

You can kinda see the damage on the end here, it was cracked in multiple places, so a replacement was necessary.

Here you can see the bulkiness of the automatic transmission and also how little space is there between the end and the frame rail, making removal without removing the engine impossible. All of the rust under the battery area would be fixed later.

I actually weighed both transmissions and by switching to a manual i saved around 15 kg (1/3 of the weight of the auto trans). Other stuff like torque converter and clutch etc. was also taken into consideration.

I disconnected the engine loom on the ECU side, pulling it then through the firewall and removing it with the engine. Makes your life so much easier by having only 3 plugs to reconnect later.

Also i didn’t disconnect either the PS or AC pump but rather left them in the car to the side, not having to reconnect and fill them again later. After a lot of wiggling about and lifting slow to not damage anything, the engine was out of the car!

Together with all of its dirt and grime collected over the years.

A closeup of the little spooly boi. Luckily no shaft play whatsoever.

End of part one.

)

)