Anti-dive, what is it?

The Anti Geometry classified as Anti Dive and Anti Squat refers to the design of suspension setup which alters the response of its components during braking and acceleration. Anti geometry affects the pitch movement of car as the car dives or squats.

How is it measured?

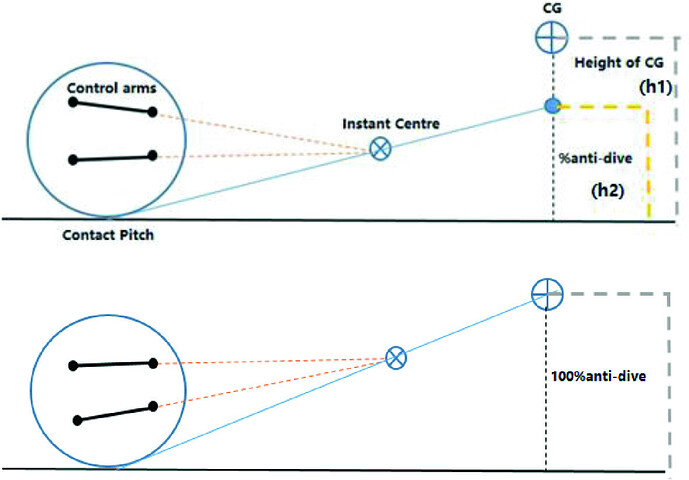

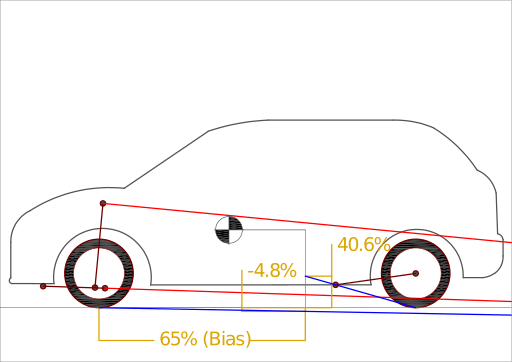

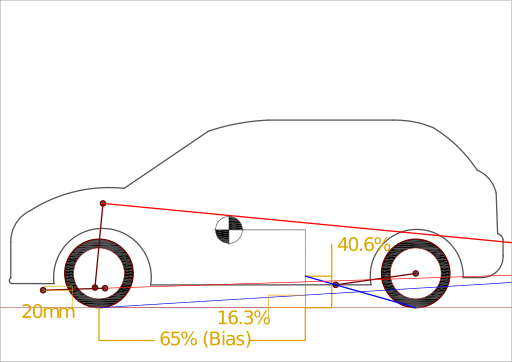

First the instant-centre is determined by following the lines established by the control arm mounting points untill they cross. In the case of a McPherson strut system, the upper line is drawn perpendicular to the theoretical steering axis, which is found by joining the strut top pivot to the lower ball joint.

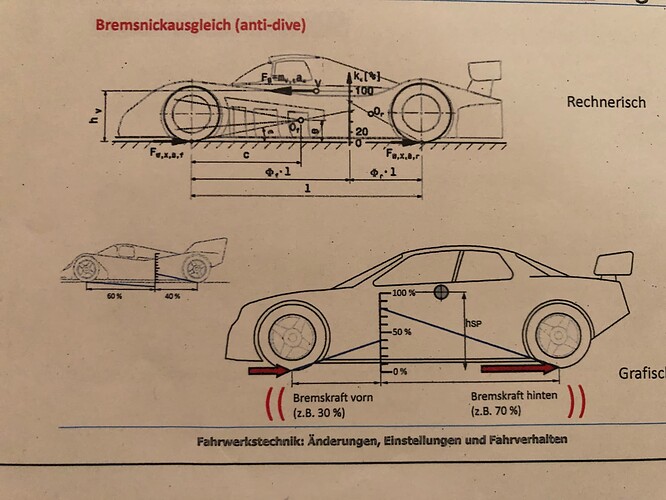

For calculating anti-dive the wheel base of the vehicle is divided according to brake bias, and at the bias point a line is drawn upwards to the COG height.

Next a line is drawn from the tire contact patch through the intant-centre. The height at which this line crosses the COG/brake-bias marker determines the amount of anti-dive in %.

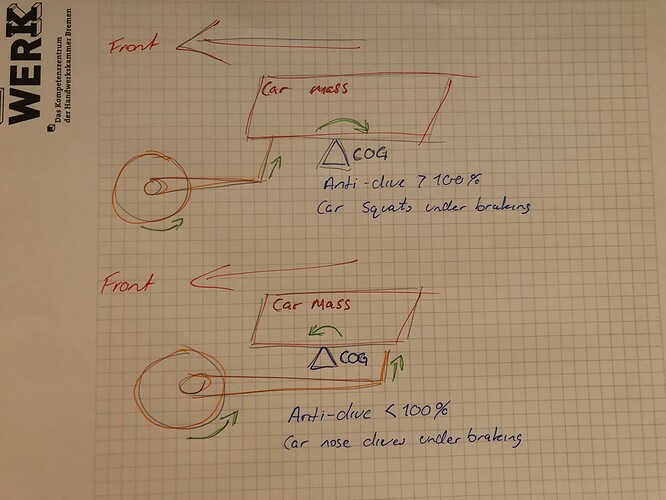

An anti-dive value of 100% means during braking the front suspension is not compressing, the braking force is working directly against the centre of gravity (COG), theoretically the most effecient.

An anti-dive value of 0% means the suspension travel hast to be first overcome before the braking force has any decelerating affect on the vehicle mass. Imagine trying to push an object with springs attached to your hands, you will have to cover a certain distance before the preload on the springs is greater than the breakaway torque of the object and the object begins to move.

How does it look on the Sirion chassis?

not good…

I must admit this is not really something I had ever considered, but after looking into it it became clear further investigation was needed.

It had often bothered me that despite having the car sprung relatively hard it was still a bit doughey when jumping on the brakes. A few problems here and there losing traction on the rear end when braking hard, and the dreaded delay when hitting the brakes to try and get some weight on the front end, it’d take a moment before the weight hit the tires.

It would seem these are all things that could be related to poor anti-dive geometry.

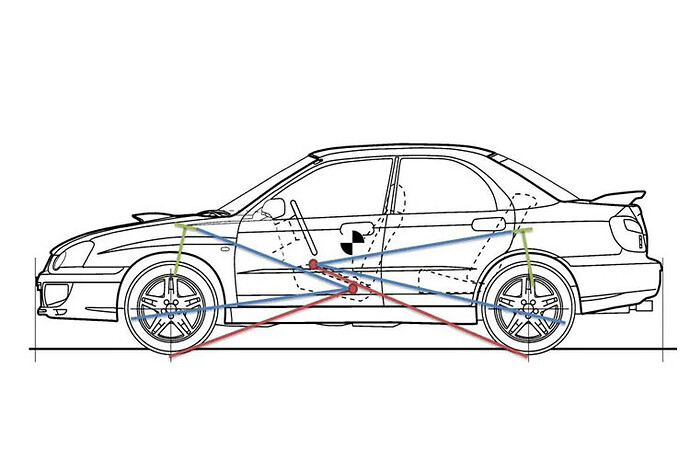

The following diagram was made using data from my own car, which has been lowered and has modified strut tops providing more castor.

The ride height has almost no influence on the the anti-dive characteristics, as the relationship between the front and rear control-arm mounts remains the same, and the COG moves in conjunction with the ride height.

The increased castor does however change the characteristics in comparison to the stock geometry, as it pushes the IC downwards. It might be worth considering the compromise in future, whether or not the improved dynamic camber and increased feedback from the castor is worth losing some anti-dive, or vice-versa.

As you can see in the drawing, the sirion has minus anti squat on the front axle, meaning the braking force is pushing the front of the car down against the suspension with mechanical advantage.

And of the 35% braking force of the rear axle, approximatly 60% is lost in suspension travel, and 40% works directly against the COG.

Proposed fix

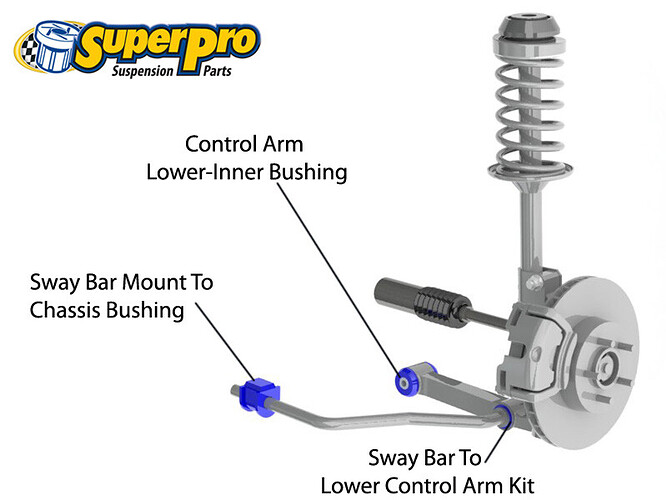

The front suspension on the Daihatsu Sirion M1 chassis consists of a control-arm/radius-rod system, where the radius-rods and swaybar have been combined into one component.

Somehow the IC needs to be raised, unfortunately the construction form of the front axle/sub-frame assembly means is not possible to raise the rear control-arm mount. The alternative to is lower the swaybar mounts.

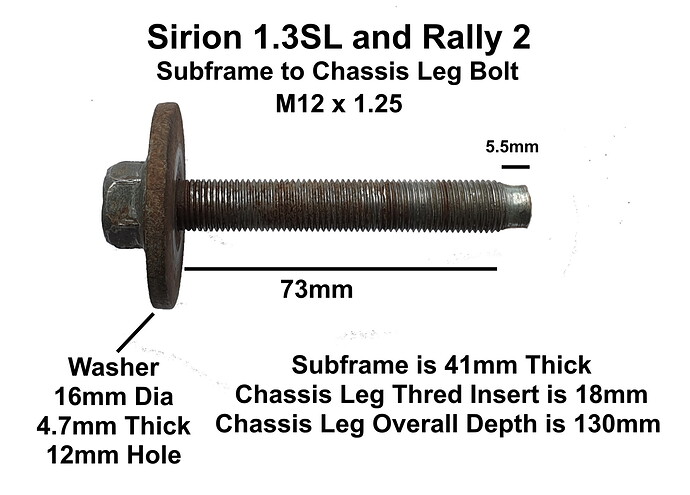

My proposal is to machine some spacers the fit between the chassis and the K-frame in the front mounting holes. This would tilt the whole K-frame forwards, raising the IC as a result.

With a pair of 20mm spacers, the anti-dive value could be increased to approx 16%. That means during braking 16% of the braking force is working directly against the vehicle mass, with the remaining 84% working against the suspension before it has any affect on decelleration.

That’s approx 20% less braking energy working against the suspension, i.e 20% more braking energy working directly against the vehicle mass, when compared to the current geometry.

Hope you guys enjoyed the write-up