First update in a while

I got the rear shocks finished up, also had them on a shock dyno before installing the new lower mounts, just to see how my valving actually was.

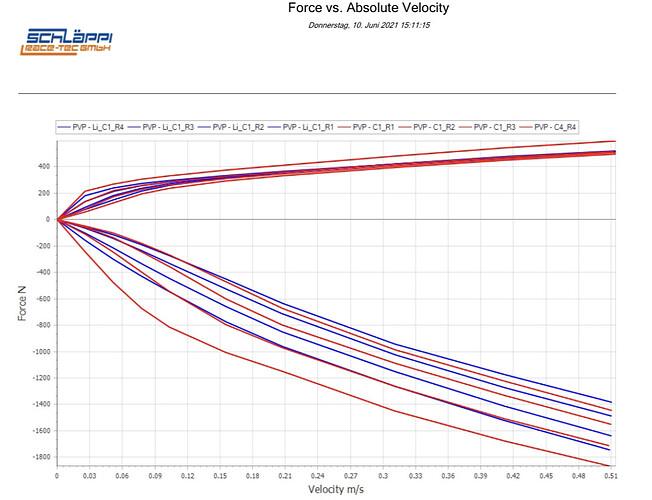

Blue is left and red is right. The difference was concerning at first, but after disassembling and inspecting everything to install the new forks, I found the left side had a noticeable amount less oil in it compared to the right. Im pretty sure this my fault from the first assembly.

The bump adjustment has a small influence on the very low speed area, and the rebound adjustment has an effect on the whole working range from low speed through to high speed, nice to know. The rebound is also pretty hard on the shocks, but I’m sure it’s a good thing as the rear axle is pretty heavy.

I also did some playing around with the front geometry, some more info can be found here

I only installed 10mm spacers, the bolts were too short to test any more than that. The results look promising, and longer bolts have been ordered for further testing.

I have been working on setting up a small mobile workshop with all my trackday gear, here are a few pics of how it’s looking so far

https://youtube.com/shorts/IBoJd3MdhJg?feature=share

I finished my tire pyrometer and had a chance on Sunday to test it out at the first race this year. Seems to work pretty well

Speaking of the race on Sunday, the weather man said it would be raining the whole day. I decided to take semi slicks, turns out it was super sunny, and the other guys were on slicks.

Still managed to score 2nd place though

Sorry it was soo long since my last update, I will try to post more regularly now that the racing season is in full swing