@DRU I have emailed you a copy of the file.

I have also been doing my own research since you raised some concerns.

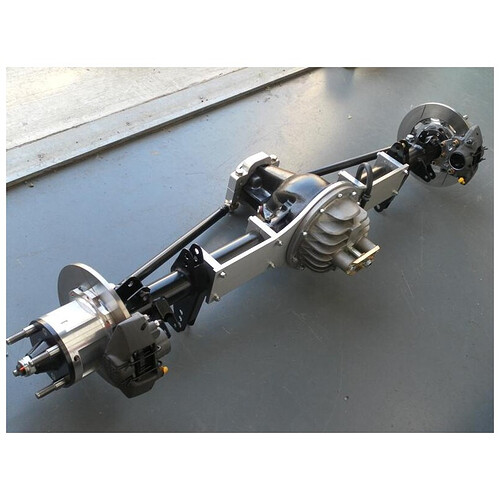

I figure the most force that the part will see will be at full extension with the weight of the diff and the last 2cm of the spring compression acting on the part, and full compression when the bump stop is being acted apon. Other forces like the dampening force and the torsional forces are very trivial compared to these.

I figure at full extension the weight of the axle is pulling down on the fork. The rear diff complete weighs less than 100kg, so I think it would be safe to say 50kg would be acting on one side at full extension. Then there is also some spring compression at play, about 2cm if I remember correctly. The spring rate is approx 4Kg/cm, so we have about another 8 kg pushing the diff downwards. Lets say 15kg for good measure, this gives a good amount of breathing room. This leaves us with a total of 65kg trying to stretch the part between the bolt holes in the fork, and the threaded hole in the top that connects to the shock rod.

Multiply by 10 to get newtons (I know its a bit less then 10, but im rounding everything up) and we have 650N acting on the part (static force).

Aceleration is a=F/m which gives us 10m/s²

We can calculate speed with d = ½ * a * t²

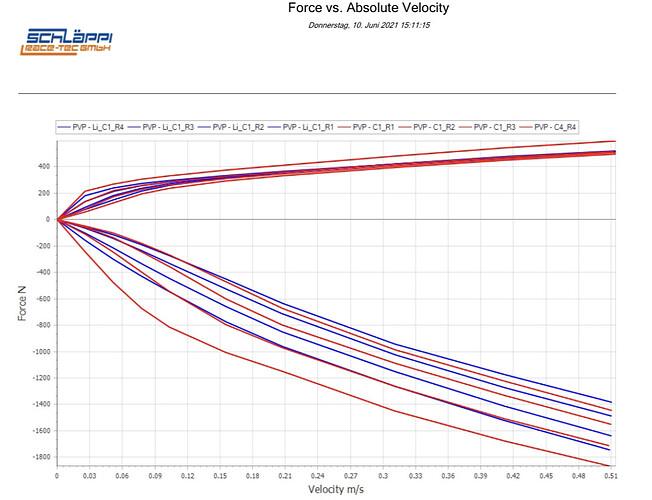

We have a maximum travel of 75mm, which gives us a maximum theretical speed of 0,075m/0.122s which is 0.615m/s. ( because the travel is dampened through the shock the actual speed would be much lower)

There is alot of deformation avaliable, there is the internal extension bump stop in the shock, and the upper and lower shock bushes. I would say 20mm, but it is likely alot more.

If we bump these values into an impact force calculator we get an average impact force of 612N and a peak of 1225N.

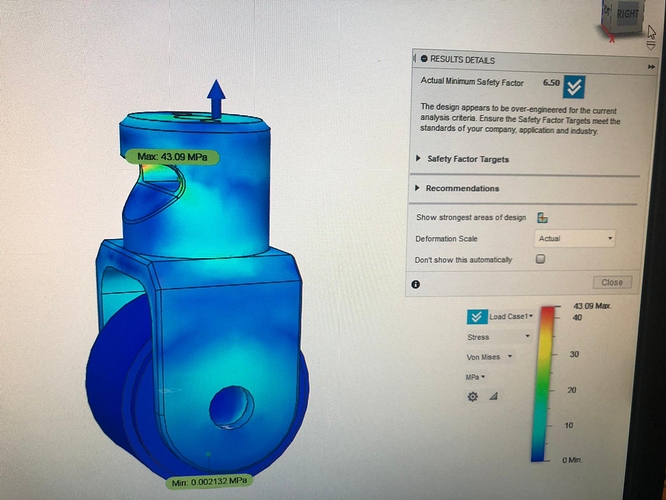

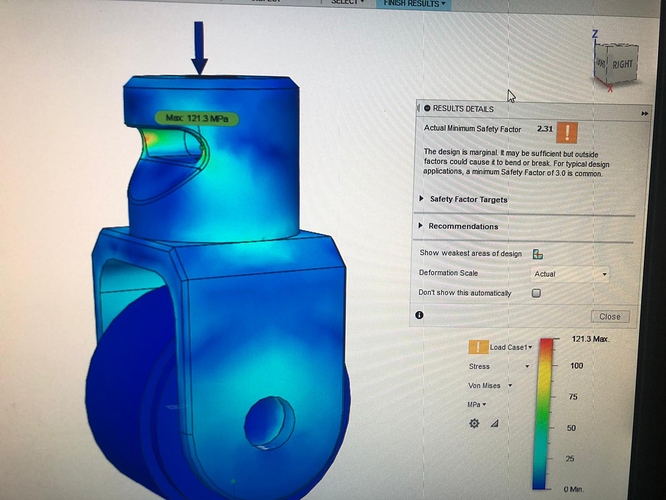

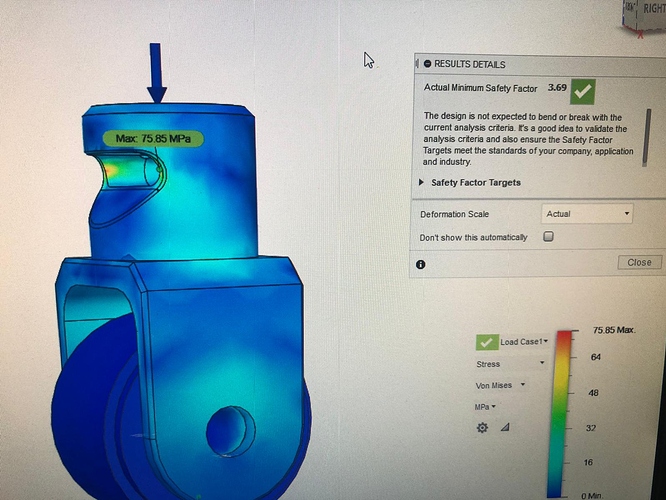

I have enttered these values into fusion 360 simulator along with the material properties of 6082T6 and ran a simulation:

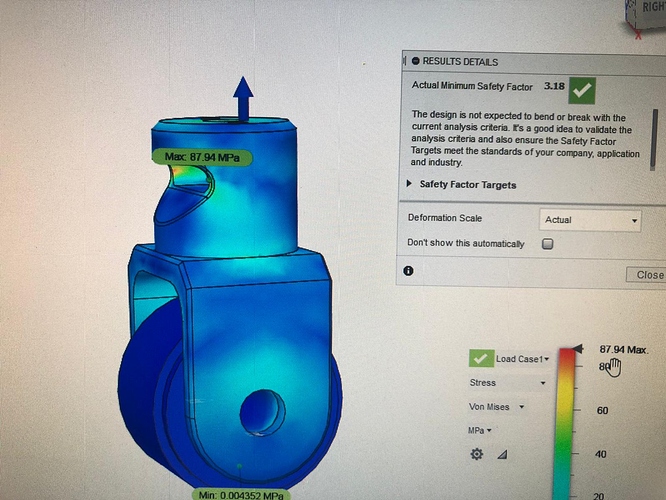

Even with double the theretical maximum impact force we are still within safe limits:

And with four times the theretical maximum force we are still marginal:

Next is impact on the compression stroke.

I figure I should calculate using the total car weight incase I get airbourne and land on one of the rear wheels with the full weight of the car, although if that happens I think these mounts will be the least of my worries

We have about 850Kg for the full car weight, mutiply by 10 for newtons, 8500N.

So if we are in the air about to land on one of the rear wheels we have 8500N pushing a mass of 850kg into the ground.

Once again we have an acceleration of 10m/s

We have 75mm travel in the suspension, and if we are airbourne i guess I just double it (I dont wanna be airbourne at all! But i guess about 7cm is kinda realistic for a situation where Id keep driving and not stop, in this theoretical situation if Im landing on only one wheel all other wheels would have to be much higher in the air!)

Lets say we have 150mm distance to allow acceleration.

This gives us a theretical top speed of 0.867m/s (once again travel is slowed from dampening, so actual speed would have to be lower)

On compression we have alot of impact deformation. We have tire deformation, upper and lower shock bush deformation, and the external bump stop. I would have to say 100mm is a pretty conservitave approximation.

Bump this into the impact force calculator and we get the following figures:

Average 3195N

Peak 6389N

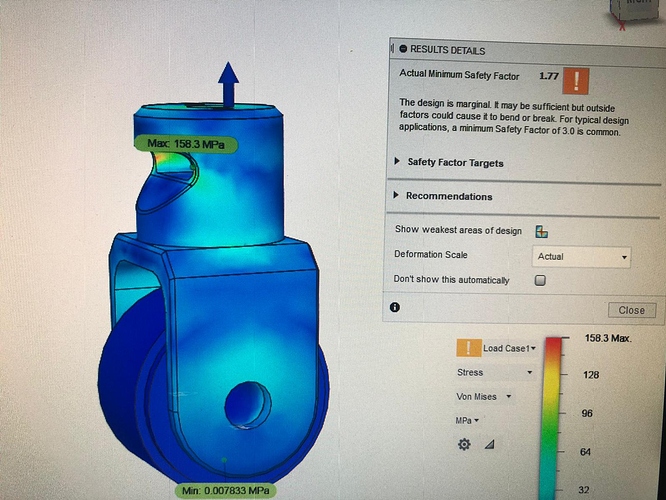

The simulation in fusion 360 shows the following for peak impact force:

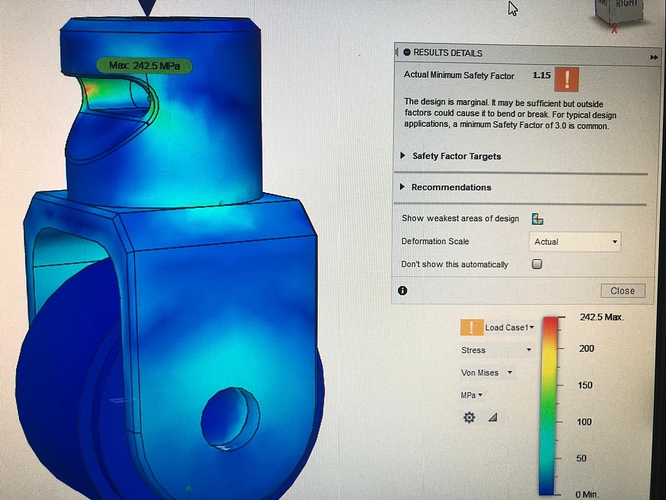

And for the average impact force:

We are not too far off the accepatble saftey score of 3, keep in mind this is me launching the car into the air, and landing with the full weight of the car on ONE of the rear wheels! And this does not take into account the springs in any way, which would absorb a large portion of the impact! Even in this extreme case the design is still marginal.

If we do the same calculations using only half of the vehicle weight we are within safe limits:

Im pretty confident they will be fine for normal driving situations. If they do break then Ill just have another pair made out of 7075 or something like that.

@DRU Im interested to hear what your thoughts are after assesment.

. I’m hoping to do a lot of VD stuff to my own car soon, and I think this topic will come in handy!

. I’m hoping to do a lot of VD stuff to my own car soon, and I think this topic will come in handy!

. I’m just not that interested in trucks, or big companies for that matter. I like the idea of just walking over to someone else’s desk and discuss a few things, rather than having to formally send a letter or something like that. I’ve worked at DAF before, and you literally had to drive to another building, if you were unlucky. So I’m not really sure what company, but I’d like to do something in the Vehicle Dynamics departement, or Aerodynamics

. I’m just not that interested in trucks, or big companies for that matter. I like the idea of just walking over to someone else’s desk and discuss a few things, rather than having to formally send a letter or something like that. I’ve worked at DAF before, and you literally had to drive to another building, if you were unlucky. So I’m not really sure what company, but I’d like to do something in the Vehicle Dynamics departement, or Aerodynamics  .

.

Unfortunately I don’t have any photos, still waiting for the photographer to post them online.

Unfortunately I don’t have any photos, still waiting for the photographer to post them online.