I thought you looked pretty stable. Hopefully Bertie looked more stable than it felt.

may have looked that way outside the cab but inside was a different story haha

b_hoves and evilhighway, you guys! Wow, braver than me. You make me smile.

Rob I did notice you get a wheel up into turn three. My suggestion is more rear spring rate. Front “soft”. That is the end that needs grip. While the cars look tall, I would go all out to get any weight down low. After than better geometry, more brakes and bolstering in the driver’s seat. I found after upping those things the front axles flexed and the calipers began rubbing on the disc. At that point I went over to M100 front bits. Do you really want to be going faster in these  ?

?

Thanks MrG. The front springs are a touch stiffer than stock, but I have a softer sway bar from a Mira in, would this keep the front soft enough? Rears I do feel need to be stiffer, guess it’s time to look at custom rear springs. Rears are currently 4.9k (3.2k for fronts) so I should be looking for at least 6+k for rears? Would there be any advantages in adding a rear sway bar at the current spring rate?

I have lowered the centre of gravity and bolstered the seats in one go by adding GTVi seats a while ago. They sit a few inches lower and are pretty comfy

Leave the front. I like to decouple things if I can. What I mean is less sway bar anywhere will let each side work more independently. Where bigger bars are working or have a positive effect I do believe such to be a compromise where better spring rates would have had a bigger improvement. But bolting on a sway bar tends to be really easy for anyone to do compared to a spring change. 6.5kg/mm or 7kg/mm, I think. I normally work in pounds per inch as the resolution is easier for me to understand. For example my installed fronts are 125 lb/in and rears are 400lb/in. I need to up that a bit since it was bottoming out the bumps stops so going up to 160lb/in front and 450lb/in rear. A coil over spring, regardless of adjustable bases is a “better” thing as they are cheaper than “custom”. What I mean is a “coil over” spring is typically 2", 2.25" or 2.5" base circle with flat ground bases, and then in a range of lengths. Often you can get what you want off the shelf. I think in my build thread it shows how to mod the back to make this easy. The spring base on the chassis gets cut off and a smaller captive base made up and bolted in place (Col Adams has the jig I made for making this easy, he owns it now). In the trailing arm remove the bump stop (mine never did anything as the arms bound up before it even bottomed out) and make a up a lower base circle to keep the bottom of the spring captive and flat. Here’s what I do like about sway bars, at the track you can make quick adjustments. The Liberty has a std front sway bar and a 2mm larger than std rear that is adjustable. Other than quite good tires (I have a better set of Hankooks on a wider rim but they are for only particular events), really good STI Brembos, Bilsteins Pss9 coilovers and springs in it (plus the requisite geoetry), the 40hp more than std, a bolstered seat and harness is the rear differential is a quite tight r180 lsd (I guess that’s a few things, but it is still 1400kg and not to special). A tight diff will make that end of the car want to track straight. In my case make it understeer. So the rear bar helps make up for that. I think I have digressed, um, the rear bar and it being adjustable means easy adjustment at the track. On my Mira I would only try a 10mm or 12 mm solid bar and make it quick disconnect and with arms at 90deg and adjustable between 150 and 200mm long. Oh the bigger rear spring rate would probably need more damping (slower).

I am also taking note of this all also as I do need improvement in these areas. @b_hoves

do we have the same springs in the front? I have sirion rsr springs lowered.

Thanks again MrG. Lots there for me to unpack.

@evilhighway I have the rs-r low springs made especially for the Moves. Not sure what the difference in the two would be. I’m wondering if it would be worth going the super low in the front to lower it another inch in the hopes of keeping more weight over the front wheels.

Just wanted to clarify: the RS-R springs I have at front rate of 2.9k and rear of 4.2k. Not 3.2k and 4.9k like I thought.

EDIT: While I was on the rs-r site I thought I’d check what the spring rates were for other makes under RS-R, L200 Miras have a spring rate of 2.9k front and 5.1k rear and the front and rear for the sirion are both 2k (doesn’t seem right to me).

I have messaged king springs too see what spring rate I have with those low mira kings as the site doesn’t have any info about it. If it turns out that kings have a softer front then I will use those but rsr don’t sound right for sirion as you said.

Funny enough I just msged them too, asking for rates and the possibility of making a custom rate set of rears

King sprig have replied that their rears have a rate of about 4.64kg/mm or 260lb/in. I have asked if they could possibly make one in 360lb/in or 6.4kg/mm. We’ll see what they say.

Sounds really good

That was the reply I got.

Obviously the fronts are 140lb

Front is spot on. More more more rate in the back. Your 360 will be good.

well for me I will swap back to king in the front and look for something else in the rear. atleast that way I know what the front is.

@Mr_Gormsby would it be worth doing the chopped in half commodore ute or wagon springs? Just wondering or would they simply be way too hard?

So, the Move current RS-Rs fronts are 162lb. I feel this is close enough to not bother with another set of front springs. I have to contact a king springs retailer to order custom springs. I get a discount at Repco, so will go down to my local branch and see what the cost will be.

find out the price and let me know what it is I May get a set also and might work if we get 2 at same time but cant guarantee I can until I know a cost.

No matter the cost, it will be at least a month before I order. I’ll head down to repco either Friday or Saturday.

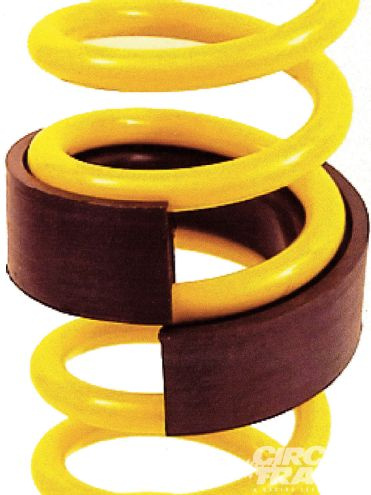

Do the old “chock” trick. A bit like doing this  . By stopping a section of the coil working you can see if or how much rate you need. I use either a stack of hard wood (that timber I had on Sunday) and jam it in the spring between coils. Imagine a section of squares of timber jammed in. I drill some big holes and add jumbo zip ties. One does not have to drive far to feel if it makes a difference. Do test carefully and as a disclaimer of liability one does not test on the public roads. For a longer or more serious test (again not on public roads

. By stopping a section of the coil working you can see if or how much rate you need. I use either a stack of hard wood (that timber I had on Sunday) and jam it in the spring between coils. Imagine a section of squares of timber jammed in. I drill some big holes and add jumbo zip ties. One does not have to drive far to feel if it makes a difference. Do test carefully and as a disclaimer of liability one does not test on the public roads. For a longer or more serious test (again not on public roads  ) I use a hollow section of steel or RHS that fits (okay I’ve squashed section in my press to make it fit) and zip tie in. The urathane seen in the picture would be best. Anyway from this you can calc the percentage of coil you’ve blocked out and then roughly predict the increased rate.

) I use a hollow section of steel or RHS that fits (okay I’ve squashed section in my press to make it fit) and zip tie in. The urathane seen in the picture would be best. Anyway from this you can calc the percentage of coil you’ve blocked out and then roughly predict the increased rate.