They don’t have a bearing.

But they should have one. It will reduce any possibility of a damaged clutch center. That is what the spigot is for. Not all dai boxes have the spigot, of the dozens of Dai boxes I’ve seen this item is a bit hit and miss as to whether the input shaft has it. Some terminate at the spline and can’t use a bearing.

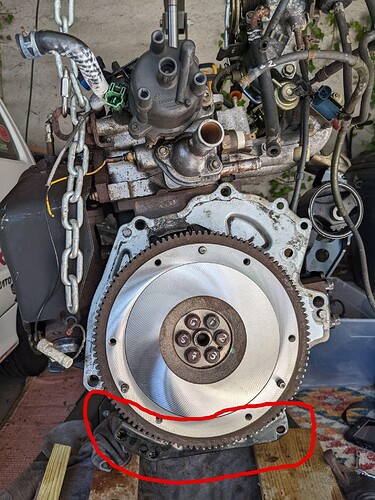

So I’ve got the flywheel and clutch back on and just reattached the trans to the motor…but I forgot the lower bellhousing backing plate and I’m unsure about the install process.

Can I just remove the lower engine brace, bolt the shield on, and reinstall? Or will I have to split the motor and trans again to attach it?

I also cannot remember how/when I removed it/the process I removed it in unfortunately (dumb, I know).

no need to split the engine and gearbox. loosen the brace (the one that goes from engine to gearbox) if anything. They are fiddly but doable. They bolt to the brace from memory.

Thanks Evil, good to know I can do it with the trans in place.

Back at it tomorrow morning, hopefully I have it back in the car tomorrow.

Notes:

-

Wish I had got axle seals, they’re right there when the trans is out.

-

The drive axle adapter part that comes off? Annoying as hell they way it’s integrated with the rear motor mount. And the bolt hidden by the engine mount.

-

Replacing the throw out bearing made me hate my life. Ended up using the old spring clip as the spring clip that came with the new one was slightly differently shaped, and after an hour of trying to get it on, switching to using the old bearing had it on in minutes.

-

Did not have a clutch alignment tool, but a 9mm I think deep socket worked perfectly for this, held it in place nicely and got the pressure plate on.

-

Engine/trans mating went smoothly, makes me think the axle shaft is lined up nicely and the clutch should be aligned.

-

Forgot to number/photograph the bellhousing bolts, so I have to go back over them again.

-

Degreased and cleaned the bellhousing but it was still kinda grimey, but at least I’ll be able to see new/fresh leaks should any pop-up after this.

-

Had a second rear main seal the entire time. Clutch kit came with one. Huge “I’m a shithead,” moment there. Especially since I also just received a second one today from Nik via DHL. Wow.

-

The replacement timing belt was only 19mm width compared to the YU9925 one on there. The belt looked in great shape, and the faint writing on the core support says it was done at 99K so 30K ago, so I elected to leave it. Was warned about belt walk and potential other issues using a thinner belt so opted to go with leaving it and coming back to it. Unfortunate as this would have been easy. New timing belt tensioner was also thinner. Tensioner on there seemed fine. The adjustments procedure with the M6 bolt was odd but I think I have it where it needs to be?

-

I have a water pump, and wanted to do it, but after electing to keep the belt I didn’t want to disturb anything and the belt felt like it spun fine via the pulley. Still, going to suck to have to do it later with the motor in the car. Kind of still considering doing it and reusing the old timing belt to be honest…

-

New thermostat housing seems to be incorrect, there is now threaded screw hole, and the bolt holes/ports aren’t clocked correctly. So I sanded the original one, cleaned it up, and put the new thermostat and gasket on.

More random photos:

good work man. I have never had a clutch alignment tool until my last clutch I did. (I have changed many daihatsu clutches). Wow that timing belt is a bit thinner but I would not be to concerned about using it. When doing a franken set up with an ed block and an ef head you have to use an ed belt and they are about 2/3 the width of an ef one. I have never had a problem with Daihatsu timing belts to be honest. Sounds like you may have an LSD box also which is a bonus . Not sure if you do but at the least I can tell you have a jackshaft (from looking at your thread pics). Just cant tell which.

To be honest I have done drive shaft seals in car and also water pimp and timing belt and while it is easier with the engine out. It is not that bad of a job.

Yes confirmed it has an LSD box. That being said, my buddy’s '94 R has a trick LSD or something aftermarket, it handles like no FWD car I’ve ever driven, I’m super jelly of whatever LSD clutch packs some Japanese racer threw in there.

Notes:

-

Progress. Backing plate was actually super easy to put on.

-

Momentarily freaked out because the clutch lever didn’t feel like it was strong enough to move the pressure plate fingers. Cracked off the trans and reseated it out of paranoia. Turns out it’s just difficult and a pry bar was able to engage the clutch.

-

That EFFING coolant pipe was a night mare to get aligned and connected to the turbo coolant line section via hose. Still sketched out it’s going to leak when I fire it up. Replaced the small coolant hose section with braided high pressure fuel line so it should be acceptable.

-

Passenger side motor mount was a total bitch to get reseated.

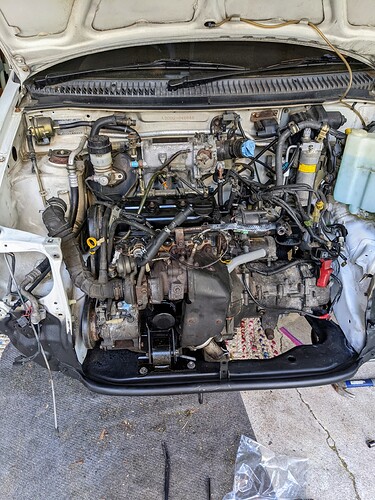

That last post was yesterday, did some more today.

-

Removed the starter to get better access to the clutch paddle mount. Super bad idea. That bottom starter bolt nut on the backside took the better part of an hour to get back on. Not making that mistake again.

-

Forgot about the two plugs hidden under the intake manifold, green box connector and a yellow round connector under the intake manifold.

-

Clutch pedal goes to the floor after connecting it, there doesn’t seem to be enough tension at all in the line. No idea what to look at first. Clutch pedal travel was as nicet when it was removed, I can’t remember if it was under significant pressure when I removed it or not.

-

Vacuum lines and all these little connections are a goddamn nightmare.

-

Can’t seem to remember where are of these brackets mount, anyone know where they go? Is this left side wire loom hung off the brake booster stud on the right side? Included a photo of that too, doesn’t seem long enough.

EDIT: Now that I’m watching this, I thought back to this. Should the throw out bearing have any slack before it makes contact with the pressure plate fingers, or should it be in constant contact? This had a small bit of slack and I’m now super concerned that’s an issue. The new TOB looked to be the same as the old one, and it was a huge PITA to get back on but I got it back on the same way and it seemed to actuate fine manually.

[quote=“turbolover, post:88, topic:3553”]…Should the throw out bearing have any slack before it makes contact with the pressure plate fingers…[/quote]Yes, indeed. This bearing should never be put to full-time service. The proper amount of slack is to be adjusted at the pedal. I think, 10 mm of play is what the manufacturer calls for, as far as I remember

10mm, okay well that does seem like the exact amount of play there was before it contacted, so I’m hoping that’s not the issue and it’s just a cable adjustment.

I also regret not greasing everything more after the fact, everything feels smooth but I think I could have been more liberal with the grease on critical points.

Clutch seems to actuate better now that I’ve adjusted the travel nuts on the pedal.

Just gonna send it and find out I guess.

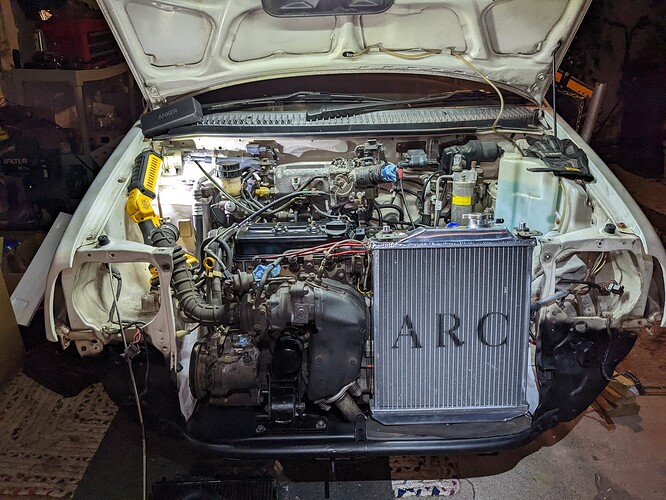

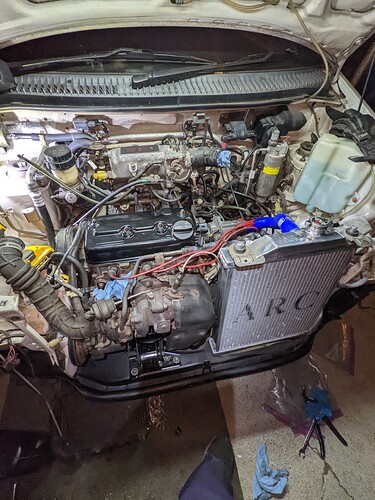

Radiator fits nicely and the fan bolts up perfectly, almost ready to test fire, have to sort out the rats nest of vacuum tubing and I forget where like half of them go, even looking back at photos.

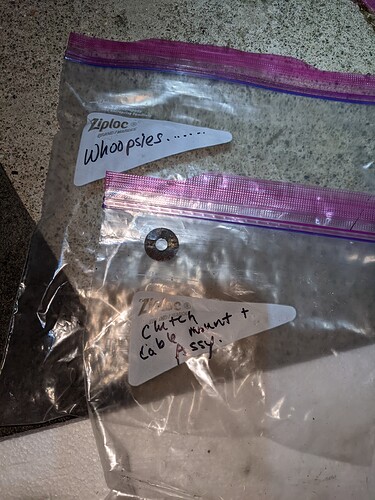

Also, have a random washer in my clutch assembly bag…and no idea where it goes. Any clues as to where I didn’t put it??

Edit: also, another uh issue I’ve ran into that is confusing me, as soon as the engine was back in, the fuel hardline on the firewall started pouring fuel out. Would not stop. Finally just grabbed the high pressure fuel hose to the fuel rail and plugged it back in.

Removed it again to move it around and route it better, fuel pouring out again.

There’s not battery in the car, so the fuel pump isn’t running, it’s almost like the fuel tank/line has been pressurized by something?

I don’t see any fuel lines I could have pinched anywhere, clueless. If it wer naturally pressurized when running that make sense, but the car has been sitting for weeks not leaking a single drop, then all of a sudden the fuel line is pouring out fuel?

From memory, I usually have to plug the fuel line also. You could try undoing the fuel cap incase there is a little pressure in the tank?

I would say that washer should just stay in the bag lol until you find you need it somewhere.

The clutch is adjusted at the pedal. There is no other adjustment point on them.

Bad news, a sway bar bracket capture nut broke off inside the front subframe and now the nut just spins.

Biiiiiig oof. Not sure what I can even do.

Maybe I can cut an access hole above it. Or cut out and weld in a patch panel.

maybe cut that bit out weld a nut on the inside bit where the hole is and weld it back in?

Current idea is to use a Dremel and cut an access flap open on the top of the subframe near the AC compressor, and weld it from there, then close the flap and weld it back.

Also, got it to turn over, but it died and now I can’t hear the fuel pump come on with the ignition.

Where the hell is the fuel pump relay in this car? I can’t find it anywhere. Or are there fuses I should be looking at instead??

Could the 30A EFI relay be the culprit?

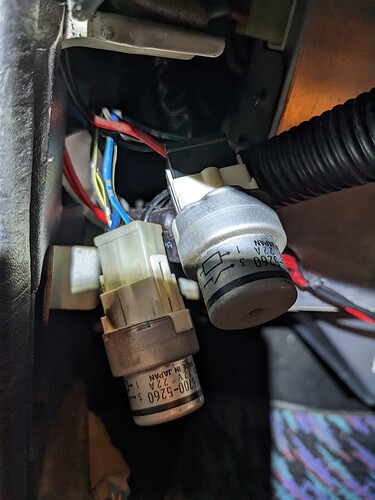

fuel pump relay is in the plastic kick panel passenger side near your feet.

Am I looking at the correct relays?

In the past I have seen them labeled 85,86,87 etc, these are just 1,2,3,4

Okay so tested both of those Denso relays, they both click when voltage is applied.

Replaced the 30A EFI fuse as well, still no fuel pump.

Pulls hair out

I have to be looking at the wrong relays.

For the broken off nut. I’ve repaired by drilling from above. Put a long bolt in, crush tube so the frame gets clamped between the upper and lower horizontal frame sections and big thick washer on the top. In fact I’ve done this when the nuts were good but was after a more rigid pickup point.

[quote=“turbolover, post:98, topic:3553”]…they both click when voltage is applied…[/quote]Clicking only means that the relay’s coil is pulling. The contact points of which feed the pump could still be burnt. Try by-passing the relay, with a jumper wire. Fuses could be tested with either a test lamp or a multimeter, when a visual inspection leaves doubts.

If current is getting through, I’d inspect the connector to the fuel pump itself for corrosion. This should be located at the floor pan just above the fuel tank