Hi everyone, longtime reader, first time post.

I am building a Daihatsu Sirion k3-ve2 race engine and track car with extractors, a 3sz ported head, intake and throttle and am trying to find a design for the cold air intake.

After watching many videos, with dyna turning, it seams most cold air intakes actually loose power unless mounted right behind the grill and Daihatsu testing with an UK based tuning company, on the rally 2, could not improve on the design.

So my thoughts are to just change the filter to a BMC performance filter and to add to my original, wide flat airbox, that sits on top of the engine that doesnt look very aerodynamic, and duct that to an intake scoop in the grill.

I would appreciate people’s thoughts who have actually designed and built their own air intakes or have knowledge in this, and can recommend which way to head.

Also by putting the 3sz head on, I am changing the fuel regulator to get more fuel and was wondering if anybody knows someone in Sydney who could tune the factory ecu?

My experience with “cold air boxes” is that they are a mod for mods sake or for changing sound. I’ve played with a couple on a dyno and found some benefit to some designs, however, one really needs to test on the road to, of course, replicate real situations. To do that I bought some cheap digital thermometers with long wires to remote probs (these days I use a Banks datamonster gauge and Banks airmouse). Put one near the entry or front of the grill, one slipped in the rubber coupler near the throttle plate/s and one at the entry to the filter. Check/compare at idle when cold and warm. Check compare in some driving situations. Alter and repeat under the same conditions .

Here is one without the shroud around the air cleaner.

If you want more torque (which is what wins track type racing whereas power wins drag races) go for a long induction tract.

I’d stick with the std air cleaner and an ITG filter if they make them for yours? Look internally at all the parts that flow air. Remove all sharp edges inside and transition all angular or abrupt surfaces that air flow will hit so that the angle is as close to seven degrees as possible since that seems to be the magic number where air will not separate from the surface and stay smooth/laminar.

Get a closed loop (wideband) O2 sensor and gauge (Innovate, AEM or similar). You can get away with a little tuning yourself using this and also adding an adjustable fuel pressure regulator.

Also go through Mick’s thread. He was altering the K3VE ECUs. Plus he had a heap of other useful stuff.

I always wondered about adding an adjustable FPR to my sirion @Mr_Gormsby but got shamed from some people about it being a useless mod

Im still hoarding the parts to do it but as i think it may be worthwhile

But sure as you add more fuel pressure the injectors should back off to suit?

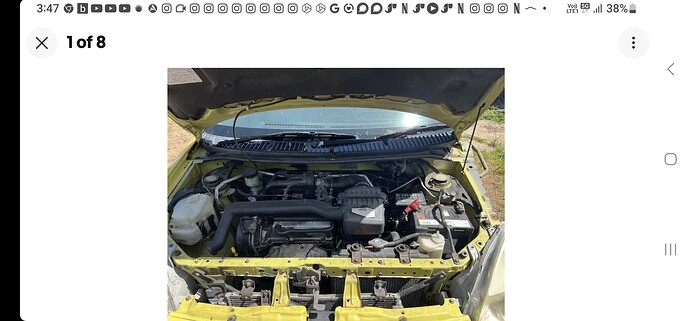

Thank you Mr Gormsby, here are photos of my standard air box and tract. I can either come of the end and pipe down to a ram vent in the grill as we are removing the AC, or would it be better to pipe directly off the air filter box and remove the flat air

tract as it has some slight deformaties just before the end, but seems smooth enough? I know the m100 pipe off the air box seems to be a better flowing pipe, but I don’t know if it is the same size?

Daihatsu testing with an UK based tuning company, on the rally 2, could not improve on the design.

Was it that they couldn’t improve on the design - or other designs just didn’t yield any additional power?

I don’t feel that the factory design is the absolute best design, but I can appreciate that others may not provide additional power, and some may/will actually lose power. Especially with the length being a critical factor, in the factory design and packaging all other items in the engine bay, there may not have been any other orientation possible than across the engine. And likewise with the space between engine and bonnet, it needed to be an oval shape.

With a track car though; with a relocated battery and less concern for water ingress - you have plenty of space to put an intake of a specific length / diameter.

The loss of power/torque may be, as MrG said, a loss in torque / power at certain rpm’s and a gain elsewhere. Even if you gain a few kw on dyno - if the area under the curve isn’t improved, is it better?

The best option is of course to test the setup, either on the dyno or with tools that Mr G has outlined.

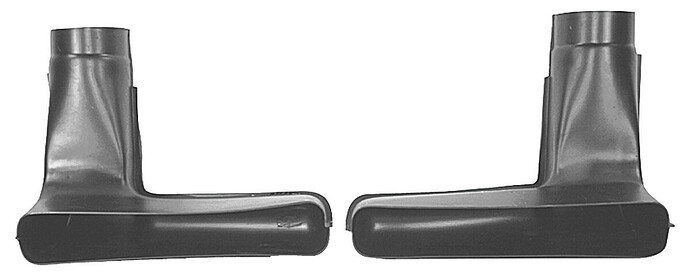

A factory performance option once directed induction underneath the front bumper. To give an idea: Scoops, Lower Ram Air, 1968 Oldsmobile @ OPGI.com

https://www.thepartsplaceinc.com/product/1969/1969-oldsmobile-cutlass-442-f85-ram-air-w30-w31-under-bumper-scoops-complete-assembly-pair/86763

A Guide to Oldsmobile Cutlass Air Induction Systems | phscollectorcarworld

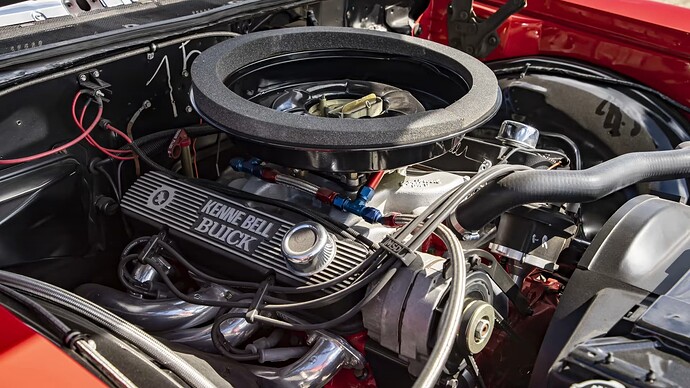

Other induction options were offered at the air filter assembly itself, for those who enjoy this type of music. A vaccuum diaphragm would move a flap which channeled fresh air from a bonnet-mounted scoop, upon demand:

Also to take into consideration, especially on higher-computerized vehicles. The following would function better on my old L 601 which has a very simple engine management system:

One key concept that pops up in both those videos is the airflow over the AFM. Our cars have a MAP sensor (plus Temperature) from factory, so we won’t run into the same issues as some cars by messing with the airflow over an AFM / an oiled filter causing an oil film on the AFM. If ones “cold air intake” was actually a hot air intake, so the air temp sensor read a hotter temperature, then the ecu would compensate and you would lose power.

Another concept that will definitely rob power - is hot air. A lot of new cars have the intake drawing from a more isolated region of cold air. The GTVI just draws air from the drivers side of the engine bay…not isolated in any way, nor really ‘fed’ cold air from the front of the car. Unless, as it is a track car you turn the drivers headlight into an air-duct.

If, as the video says, there is no vacuum behind the factory filter, then adding a BMC filter may not make any difference at all. However, ‘extending’ the factory intake to be fed air directly from the bumper would be a good option. There are several ones on this site across the different Daihatsu engines:

The Shorty:

The Straight to the Drivers side:

The Fancy one

The Follow the same path as the factory K3VE2

The Factory Airbox, but with a feed from front bumper

The Long tube and low filter

I went with the semi-longer tube and eventually put a panel in to separate the filter area from the back of the radiator and also put a cold air feed from the front bumper - similar to the face lifted models D-Sport bumper duct

I had started playing with turning the fog lights into an air duct for the air filter (or a brake cooling duct) and/or also turning the passenger headlight into an air duct for the filter…neither came to fruition before I left Adelaide. The lower headlight section of the headlight did have a nice bowl shape to it and from memory once you dremeled some parts off, you could fit a 2.5 or 3" hose to it easily.

Thats exactly what I am planning, my question is should I duct straight off the factory airbox OR connect to the end of the factory air tract, that I have shown in the pictures above?

Will either way make any difference?

Also I have already purchased a ram scoop that will go directly through the front grill or fog lights.

The ecu is largely open loop. That means the injectors aren’t regulated to know more fuel is being added. The O2 sensor is narrow band. So it does not get data to show the actual fuel to air ratio. What feedback it uses is on for steady cruise situations where it will see if things go richer or leaner and it will adjust to a steady state. As for being rich or lean it does not know as only a wide band O2 can do that. Aftermarket wideband normally have an narrow band output for the ecu, you have to monitor the data on the gauge and enrich or lean the mixture via the reg. I think yours is without a fuel return to the tank. I’ve never put an adjustable reg on a non-return system so you’ll need to check into that.

The only way to know is “testing”. Do it for std and then for the mod. For temp get a few cheap temp guages, go for a drive with someone watching the gauges. Record data with norm engine temp at diff loads/rpm. Get or make a manometer and redo the same testing to see if the pressure changes. If things are cooler air will be more dense but it is nice to know if your air charge is more dense. A factory (or even after market) air flow meter doesn’t know if things are more dense. Some efi Dais don’t even have one and the ecu just runs on set tables for different water temp, throttle position, rpm, cam sensor and closed loop ecu.

Thank you, Mr Gormsby. Will do ![]()

@Mr_Gormsby yeah ive kept a 2nd fuel hard line that surprisingly pops right into the fuel/brake line mounts under the car and was going to hack up an old fuel pump carrier to remove the in tank filter and mount 2x through barbs for supply and return for the fuel

Then put an engine bay mounted subaru fuel filter and adjustable regulator

Mick did the same thing with his auto-x sirion I believe

I have a wideband and gauge fitted so will definitely look into this option later

I believe the OEM setup uses an in tank simple pressure relief valve to recirculate in the tank and that what i thought was a pressure reg on the fuel rail is actually a pulsation damper

Sorry to hijack OP ![]()

![]() but youre building the same engine as me for the same purpose so its all good research

but youre building the same engine as me for the same purpose so its all good research ![]()

If you’re sticking with the factory airbox, I would replace the factory engine cover / air tract with a duct to the front of the car.

OR, try to blank that side off and drill into the airbox and run a duct into the other side of the airbox. Easier if you relocate the battery. That side will give you more options to feed air from and keep the inlet away from the exhaust manifold and it won’t sit on top of the engine itself.

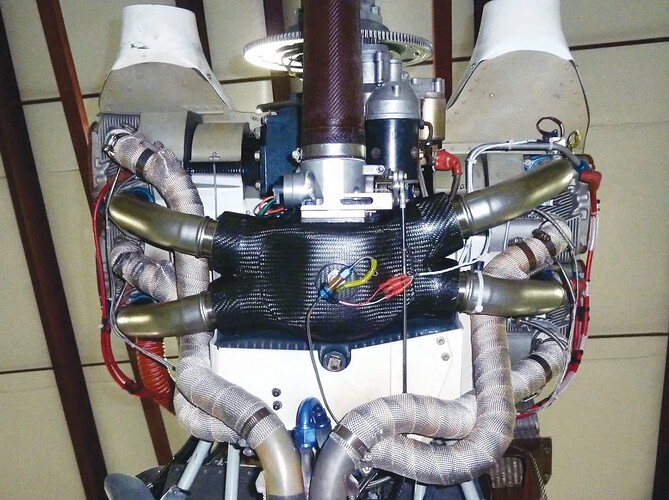

Using carbon fibers for constructing induction bits:

Drawing-in cold air from what we call a “plenum”, taking advantage of both lower temperature and increased air pressure created by windscreen air-deflection

Cowl induction functions in a similar manner, using a bonnet-mounted duct

What I was always planning to do with my fuel regulator, as suggested by Tim Hart of Compact Motorsport, is because I am swapping to the large port/valve 3SZ cylinder head as mentioned earlier.

the cams in the engine (K3-VE2) are the best of them all and drop straight into the 3SZ head without modification. It will probably run a little rough at idle or low throttle opening on the factory ECU unless I bump the fuel up a little to match the added air flow.

This is easy enough to do by fitting a 1/8 NPT barb in the blank end of the fuel rail and a return fuel line back to the tank with an adjustable fuel pressure regulator. I also need to remove the fuel pump and block off the factory in-tank fuel pressure reg which is a very easy mod.

Have you considered Compact Motorsport’s Link ECU’s?

It would have to be the best option to ensure the most can be gained from head swap and intake/exhaust mods. And to know you won’t run into any fuelling issues.

Your question about anyone in Sydney being able to tune the factory ecu - I’m not aware of anyone doing that. And as MrG said, Mick’s modification of the ECU is more an overclock of the ECU.

Out of interest @Nrop how do you carry out the in tank pressure relief valve block?

As if i can block that, utilise the in tank filter still and just add a return line through the pump housing down to the pump pickup itll be tonnes easier (since i already have electrical bulk head connectors on the housing to deal with spacewise

Hi Lando, we are not actually up to that at the moment, we have just completed the engine build with bigger high compression pistions, ported and bigger valve head, but today we installed the NPT barb in the end of the fuel rail as we have other work going on in the workshop.

Next week we will fully rebuild the gearbox and install a LSD from japan and hopefully get it back in the car. Then we will attack the fuel pump and regulator and guage. I will try to take some photos and let you know how we went about it.

LSD was one of the few biggest transformations, right up there with getting the spring rates right and a quick rack.