can’t remember off hand what the bore size is. from memory, it is around 46-50mm. I would actually have to take them off and measure them again. I had been searching for info on the autronic quite a bit.

The autronic is now read-only but I have been getting a little bit off there but still struggling a bit.

The manuals from the sit help but not enough but last night I stumbled across a bigger jackpot and found a manual that cover’s a lot more. Very similar to the bits n pieces I got in the bag with it but much more info.

I feel now this will give me more confidence to get through and work it all out. Of course, the main info is 4,6 and 8cyl cars but it’s more than I have had previously and enough to get me stumbling through it.

Try Forums - Autronic MRM Forum. A really helpful forum. Admin is based in Sweden.

The bores of the ITBs will be too big. I had and might still have some ITBs that I was going to use, but after doing the math I put them to the side till I could find the time to choke them down. From memory 38mm was about right 40mm getting too big. There are online calculators that can help. Some have more variables some less. The most basic, one just punches in desired max rpm and cylinder capacity.

Yeh that is the forum that is now read-only. It does have a lot of good info and it will come in handy for when I get stuck and need to get to the more finicky side of things. For now I just need to really pick a bit and tackle that first which I am starting to do in my own weird unique way. Persistence and stupidity will get me there eventually lol.

I really don’t remember the size of the tb’s to be honest. I am really just guessing. I went by the basic logical mathematical equation and thought well these are coming off a 2014 triumph tiger 800cc motorbike so they should be in around the right ballpark. I have choked them down a bit with the adapater’s I made to mount the airfilter’s. They do work so that is a good start. If an the end of it all I decide I really dont like them then I can always go back to the original manifold which I have kept intact for just such an occasion. Also they are choked to normal intake manifold size when the air enters the chamber’s and the adapter to fit them is made from a stock manifold and don’t ever think I have made them in an efficient flowing manner as they are completely not and probably most people seeking such perfection would be horrified hahahaha. I got them to work and that was the goal and now it’s time to get other things together more to try to bring it all together and make it all work, iron out bugs and have some fun. Long way off but that’s the plan and goal.

The 800cc Triump has an 10 000rpm redline so needs more air. Great work though.

Oh, that’s not good the forum is closed. Sigh.

Gormsby hopes all have had a great Christmas. The start of his holiday season got off to a poor start with this. He’s got a sore neck, back and will have lost most of his holidays just getting back on track with a/the replacement.

The daily-drive-and-race-car-tow-vehicle had someone make an illegal turn in front while Gormsby was traveling through a green light. The other driver didn’t look, was in a hurry and turned across Gormsby’s path. His 4x4 spun 180degrees anti-clockwise and is shown only a couple of meters from the point of impact. The big hit was on the nearest side even though the left hand front corner looks pushed up (it’s pushed over). The Skoda that cut in front copped a hit in front and and in the back as the rear spun and hit the tray and rhs door of the 4x4.

The other driver was issued an infringement notice and is thus “at fault” so Gormby’s insurance company organised a rental car (new MG - Chinese car pretending to have British heritage - rubbish car but transport all the same). So to be sure there was a permanent replacement and having a rental car the local “for sale” avenues were scoured and a similar replacement found.

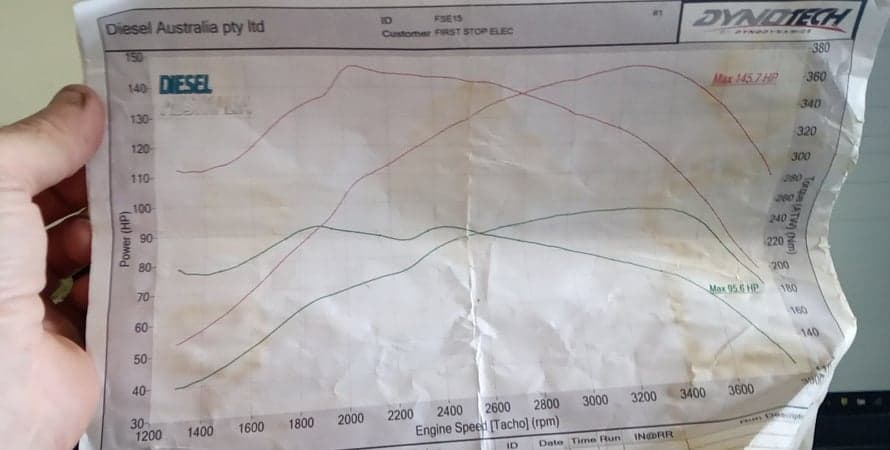

Pretty healthy power and torque wise with 145rwhp and 390nm of torque from a good dyno tune. There is a custom turbo that was on the silver one that will go on (same turbo as factory but some porting, thermal coating, balanced and spools faster), and hope to get a better PX ranger intercooler that was also on the silver one for a while on to bring temps down.

Hope to get the silver wreck back to swap the wheels, Bilstien suspension and keep the lower K motor from the original. Unfortunately the huge PWR intercooler on the silver one will be toast. It’s been such an unwanted hassle due to someone’s inattention. But the outcome could have been worse.

It’s not a Daihatsu, but the point here is, L2D brother and sisters watch out for others and be aware of what you and others are doing while you are on the road. I hope you have had a Merry Christmas.

Glad the damage to you isn’t too bad Mr G. Like you said, it could’ve been much worse. When I was young, the first thing my driving instructor said to me was: “Every other driver on the road is a dickhead and they will do the stupidest thing possible every-time. Drive with this in mind and you will be much safer”

This was pretty instant. Big truck in front of me and the guy cut immediately as the back of the truck passed assuming nothing behind the truck. My 70kph and his 70kph. Had time to brake but only a few metres of scrubbing off speed . He didn’t slow at all. Didn’t see a 4x4 coming at him as he drove into my path.

Damn, glad you’re okay. Cars can be replaced, you cannot.

As long as Gormsby is ok then everything is ok

Thanks, the body is okay and just about back to normal. My depression was returning prior to the accident and I am working hard on that. So tired and just wanting to sleep. Sleep a bit get up do a task and repeat. Too many projects, too much junk around. Need to sell the WRX and get rid of some other stuff so I can have room to work and finish the house renos - the latter will still take a couple of years.

Ok it’s been a while so I will do a bit of an update on whats been happening and what i am doing with this.

I noticed the ejde wasn’t quite running right, So I did a compression test and no.1 is down under 15% compared to one and 2.

No biggie really but I do have a head gasket and if it is a valve then I can get a new valve if needed.

In the meantime I took the engine out and put in the efdet engine I have here as I have never ran it before and wanted to see if it runs etc and the ejde will be easier to work on with it out.

The efet runs ok but it is smokey. Not sure if it is the turbo, rings or valve stem seals. Either way it’s fine for now as i am moving one to other stuff with the ejde so i can get it back in but want to be able to move the car should I need to so at the moment the efdet is in there temporarily.

Now the ejde. As previously seen in the thread I had got some itb’s for it and got it working.

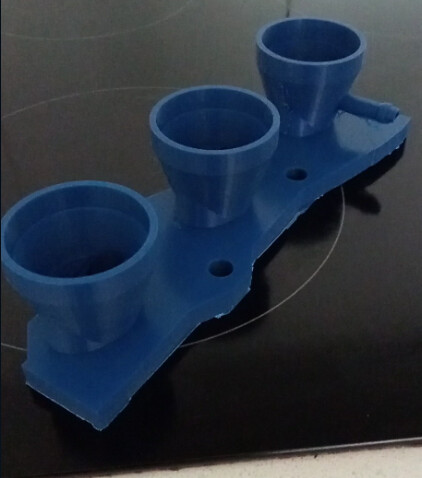

In the meantime I have acquired a 3d printer and have began to fumble my way through using cad software and am currently working on building an intake manifold to connect the itb’s too.

I am working in PLA at the moment as it is heaps cheaper to proto-type in than carbon fibre nylon or abs which is what I will be using for the finished products. ( I need to learn how to do all this with my printer also)

Im taking it step by step and getting things done simply first and then building upon them. From using a paper template to getting it on the programs and then making it really thin first to get the hole alignment’s and sizing right before building them up and overcoming issue’s and finding solutions with my small print bed.

Much more refinement is needed, getting there, but this is pretty much the first draft.

Prototyping is getting there slowly. This still needs some more tweaks but getting there. Then I can upgrade my machine and look to cf nylon after doing some abs.

still playing around with prototyping. After spending a week or so trying to improve on the design above. I did nothing but make it worse for myself and how it came together. The middle bit pictured above is about what it will be just a touch shorter in the trumpets and a lip for silicone joiners to catch on and the straight part will be a little longer at the trumpets to accommodate the silicone joiner’s. In the end I thought it was better to use the silicone joiners to account for the couple of mm differences rather than re-write the whole book.

I haven’t done much here at all since moving but I did get motivated yesterday and did a home wheel alignment.

It looks to be better than what it definitely was. I have also been fixing my 3d printer and it is now printing again and I need to get back to teching myself another cad program. Onshape will be the one I try. Tinkercad while basic and can get some stuff done and is fun I find it is to limited.

Have you tried Fusion 360 yet? I have no idea what Tinkercad is like, but Fusion is a nice and easy tool in my opinion. My only issue is that I’ve worked with Siemens NX for almost 6 years now because of school, so I have to get used to the ‘basicness’ ![]()

I have heard of fusion 360 and heard of many people liking it. However from what I have seemed to find is it is way more limited for the free/ personal version than the paid version.

I was either going to go with free cad or onshape.

Tinkercad is pretty much like building leggo blocks style but it does work.

I have finally found a can of motivation to get back to doing something again. I was a bit frustrated after moving to a semi outback location in that I got rid of most of my sheet metal i had and I really wanted to do something about the rear guards.

So a few days ago ou clothes dryer died. It had been on its way our for about a year and we had been persevering with it. YES It’s Summer and damn hot here and why did we try using the dryer?

Well Bushfire’s came 5km’s away from town and everything just smelled like smoke so we tried the dryer so our clothes wouldn’t smell like campfire.

Anyhow broken dryer means I got some sheet metal. After taking it apart and seeing what else I could salvage I put the sheet meat aside and today I got to this.

Bad pic I know (that’s so you cant see my bad welding properly).

For those that don’t remember these are a 205 50 15 and rims that are 7.5 inch wide from memory.

Before just slapping on the main panel. I took off the wheel and put about 12mm on spacers on so the wheel would poke further and I could curve the metal to where it needs to be for clearance.

I took the spacers out and re-checked after i put the panel on and I can slide my fingers nicely between everything.

I’m yet to do the other side but I have the panels ready to go and will get to it soon. Then I will obviously need to grind bog and paint what I have done and make it look pretty.

In other news my 3d printer has finally been playing nice again and I have made some pod filter adapters for the ITB’s

rims are 15x7 rotas

Thats it I can never remember the width. Thanks @Mr_Gormsby

Are those Triumph Speed Triple throttles? How do you plan on making a manifold to mount them, I’ve been trying to figure something out but my limited part making skills and laziness haven’t been helping. ![]()