With itchy feet I set to again tonight with a plan to get this all back together again.

I gathered my tools and things and carefully jacked the fuel tank up into position, attaching the fuel gauge plug, fuel return line and fuel feed lines before raising it high enough to put the 4 bolts in that hold it to the underside of the car. This is a better system than the bench press system employed on removal!

With the tank refitted I could then fit the new filler neck, I put a tiny smear of silicone grease on the inner edges of the fill and breather pipes and wiggled them onto the metal ends of the brand new filler neck, then wiggled the filler flap end into position with the gasket already fitted and did up the 2 brand new fine thread bolts that hold the top of the filler neck to the inner wing

from underneath I could then do up the 12mm bolt that holds the neck to the car, about mid-way along. This is the underside view

Then finally tightened up the hose clamp where the filler neck meets the rubber joiner for the tank, and the same for the breather hose and we’re done I think?

I gave the underside a few more squirts of dynax wax on a few spots I’d either missed, or hadn’t coated as well as I could have, then used a petrolly rag to wipe down the overspray on the exhaust and wheelarch lips. I also reattached the rear wheels so I think its all done now?

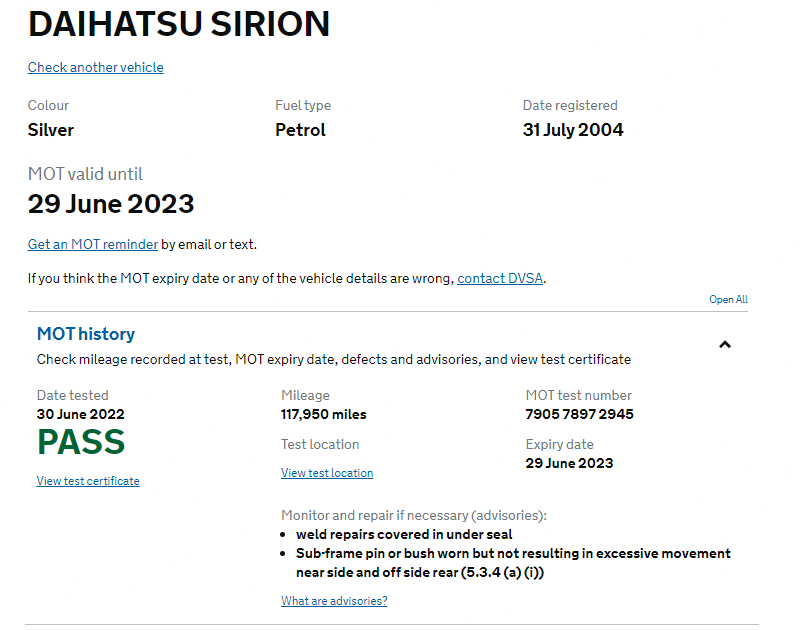

All I need to do now is lob a couple of gallons of petrol in from some jerry cans and then see if the car will start! I’ll drop it down off the lift tomorrow or over the weekend, get some fuel in it and then run it up and down the drive a few times to clean off the surface rust on the front discs from 2 months of inactivity. Then I need to book it in for an MOT!