From Russia, with love DHL

Check out my new bush(es)

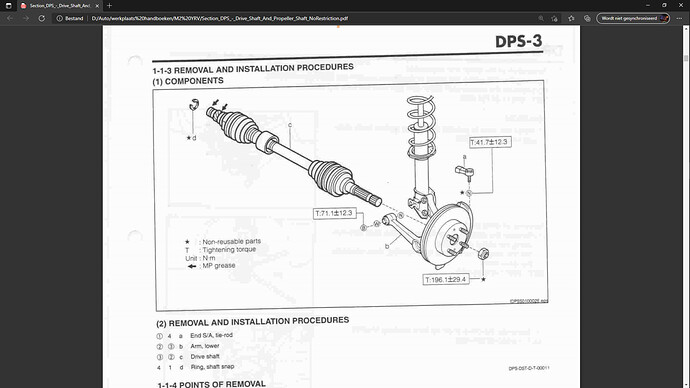

Front end completely rebuilt, the arms arrived about 25 minutes after the PU bushes, I called my pet garage about pressing in the new bushes and they said they were stacked and it’d be 2 weeks time at the earliest so I had a stab at doing them myself with the hub puller. I was purple with rage due to a dire morning of work issues, but was able to press the rubber bushes out of the lower arms with the press, lubed up the voids (fnarr) with silicone grease and pressed the new PU bushes in with minimal fuss. I then loosely bolted the arms into the subframe, tapped the locating rod bit of the balljoint into the bottoms of the hubs and did up the castellated nuts to tighten them into position, then fitted the split pins to keep them in place.

Then I fitted the ARB bushes, put the ARB ends through the new lower arms and did the nuts up a bit to keep it in place. Then I sliced the u-clamp bushes, wrapped them around the leading edge of the freshly painted ARB, and clamped them down with the metal clamps.

I then went and did the nuts on the ends of the ARB up tight to pull the ARB > lower arm top hat bushes into position properly.

It all went together fine which was a big relief. So thats the front end refurbed with all new bushes and arms which should help a lot.

I tilted the nose of the car down and took one back wheel off, the rear beam bushes are a bit trickier as I don’t really want to drop the rear beam entirely, and the bolts that hold the leading edge of the rear beam to the body mounts are super tight. I’ll go out in a bit and see if I can get the ugga dugga on them to see if that will tempt them out. Then I need to carefully support it all on the trolley jack and try to press out the existing bush in situ, then put the new ones in one at a time.

Here are some ‘this man has just run me over’ style photos of the finished job

As you can see, I sanded down, vactan’d and enamel painted the ARB itself and the u-clamps in matte black, the new bushes are bright yellow which gives a nice contrast

Its quite a simple setup, but entirely effective.

I took it out for a very quick run and initial impressions are good, the ride is no more firm, but there is less clonking over poor road surfaces than before - at least from the front end. It’s also helpfully dealt with the advisory for perished lower balljoint dust covers as I’ve replaced the entire arms.

I had a go at the rears which was an abject failure - I can’t get the nut to release from the through bolt that holds the rear beam on, even with the ugga dugga. Its an awkward spot on the passenger side (access is better for the drivers side actually) due to the location of the fuel tank so I’ll have a think about what to do with that. It might be a job for a proper garage potentially? I’ll call my pet garage up tomorrow and ask them when they might be able to have a look and quote for the work. I don’t imagine it’ll be particularly cheap to do if they want to drop the whole rear beam off for access

We’re nearly there though

. I guess we’ll find out!

. I guess we’ll find out!

. The kit from ‘ert’ looks quite similar to the ‘autofren’ kit, don’t you think?

. The kit from ‘ert’ looks quite similar to the ‘autofren’ kit, don’t you think?