Here we are, back on familiar ground. Changing another clutch. Except this time the work is quite a bit more radical. The Sirion needed its clutch changed, it judders from cold and has led a hard life. Its managed 120k so I’m not too displeased with its innings. FWD clutches are a pain in general, the clutch in the sirion is easily a 5-spanner job. Because its a smoll car, with a transverse engine, the whole ruddy lot has to come out. The engine and gearbox are the entire width of the front inner wings, there is about 1" either side of the engine when its in, and with a full engine cradle subframe you can’t drop one side down to do the job. There are two options. Remove the entire subframe with engine in situ, or unbolt the engine from the subframe and pull it out the top.

Honestly, neither option is particularly palatable. In the end I chose to take it out the top, as taking the subframe out requires undoing the steering column as well as all the other things, and then lifting the body off the whole subframe assembly which looks 0/10 for fun.

I’d spent several evenings this week doing the prep work. I’d disassembled the front suspension, removed the driveshafts, drained the gearbox, drained the coolant, removed the intake manifold, throttle body, hoses, about 8 million connectors and the gear linkage from the engine end. I’d also disconnected the exhaust from the downpipe.

I have my brother coming down tomorrow to help with further work, but had some time this afternoon to carry on the prep work, and made good progress. I ended up hiring an engine crane from a local place

(Beaver Tool Hire, fnarr etc)

I bought myself a load leveller from ebay for £20 to make things easier. There are relatively few pics of the next bit because it was really humid, I had a very heavy engine on a crane swinging about and had limited access. I was able to undo the 3 engine mounts with relative ease, and had the engine firmly attached to the load leveller, but it became apparent that there wasn’t enough room to get it all out without further dismantling. I had to remove the front bumper, the radiator & the radiator support bar to clear the front up so I could swing the engine and gearbox out.

I was still having issues, as the PAS pipework and AC pipework was attached to the pump and compressor respectively. I couldn’t remove these until the engine was free, so had to be a bit of a redneck. With no choice, I had to undo the AC pipework from the radiator, letting loose a poison cloud of death r134a. I ran away for a bit to let the gas escape, not my proudest moment but needs must in this case. For the PAS pump, I ended up pulling the top hose off, I lost a tablespoon of PAS fluid but was able to then wedge the pipe up out the way.

This finally allowed me to lower the body down, lift the engine up and with an alarming thunk noise it was free

You can see the rad brace bar and the PAS pump folded back onto the scuttle and the loom tucked over the passenger side wing. The passenger side headlamp got a bit savaged by the engine as I wheeled the crane out the way, it might be OK with a polish but may need a new unit.

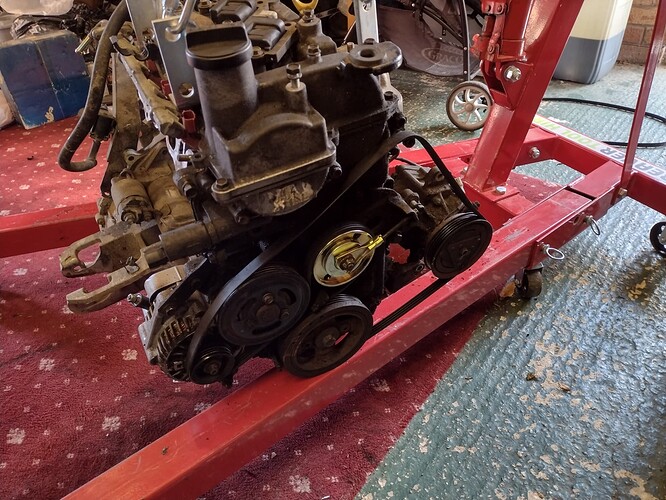

With the engine out, I could remove the aux belt tensioner. This was held on with a rather severely chewed bolt, the issue I had was that in situ, there is about 1" between the tensioner nut and the ABS block, so the only thing you can get on it is an open-ended spanner. Someone had been at this before I got there so I was unable to change the tensioner pulley or aux belt when I changed the alternator. With the engine out, I could get a snug fitting 14mm hex socket on the nut and undo it easily.

Spot the new part!

Its hard to see in this pic, but the tensioner (gold bit) is tensioned by a long threaded bar that goes into a bracket. This has the effect of trapping the aux belt until you remove the threaded bar, but is impossible to see in situ. Doing it with the engine out was a doddle though. I can’t do it up tight yet because I need to refit the engine, then reattach the PAS pump (top right), THEN tension the aux belt up. I also need to make sure I’ve run the belt correctly, I think I have, but not 100% sure.

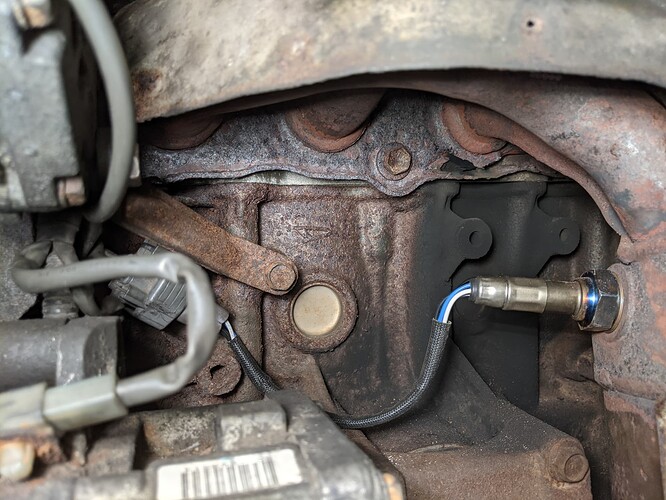

While I was in there, and the main reason that I left the downpipe attached, I could get a good look at the mounting flange. This joint leaks, and after having a closer look, the issue is that the captive nut on the downpipe side of the flange has rusted away and been replaced with a cut down spring and nut&bolted. The issue is that there are three ‘legs’ of captive nut left which means the nut on the downpipe side can’t tightened up properly so it doesn’t seal right.

With this off the car I could get a rough file in and file the leftover ‘legs’ down flat so that when this all goes back together the nut will sit flush with the flange and should make it seal properly. I ought to have bought myself a crush gasket really, but I intend to have the exhaust replaced with a bigger bore stainless one next year so it’ll do for now.

I lowered the engine and gearbox down onto the legs of the engine crane so the ram isn’t taking the full weight, its basically just keeping the arrangement upright with the weight taken by the crane legs for now.

So thats it for today, tomorrow we’ll pull the gearbox off the engine, replace the clutch with the LuK kit I bought several months ago, refit the gearbox, fit the engine & gearbox to the car and then reassemble everything. further updates to come.