So, a bit more info on the exhaust issue. Here is a closeup of the exhaust → ARB bracket interface

The shiny bit of exhaust in a U shape is where the underside of the exhaust hits the trailing edge of the ARB mounting bracket.

It doesn’t half clonk when they hit each other! Following the advice of @TPG I wrapped the hanger rubber with a cable tie to pull the exhaust up higher. It only raised it about 10mm because then the exhaust tip fouled the top of the cutout in the rear bumper, but its lifted it a bit

The final bodgery for today was to cable tie on a protective cushion in the form of some leftover heavy duty rubber sheet cut to size. This is about 5mm thick and reasonably heat resistant

Not pretty, but it did help. I took the car for another run for about 20 miles earlier and the clonking is now less obvious, and only happens over the bigger bumps & potholes so thats improved it a bit. After coming back I checked how hot the rearmost bit of exhaust was getting and while it was hot, it wasn’t really hot - I could touch it with my hand, but it was too warm to grab hold of and leave you hand holding it. Would be fine with a glove though.

@TPG -some/all of this kerfuffle may be a result of it being a pattern part rear exhaust, the OE one might have cleared it better but was more ‘holes’ than remaining metal so got binned off a while ago.

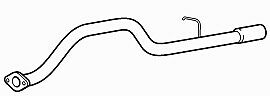

What I need to do now is some proper work on it. The rear section of pipe looks like this

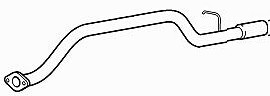

The issue is the that drop to the left of the hanger arm in that pic is too far forward, and too shallow to adequately clear the ARB bracket. It needs to be modified a bit to improve clearance so its more like this

With a much longer middle section where it rises over the rear beam and a shorter straight end pipe section, but keeping the hanger arm is about the same place. I had a think about some cutting and welding, removing the hanger arm, cutting 3" out of the final straight pipe section and re-welding the hanger and end tip back on, then using the 3" of pipe to lengthen the centre bit, but this is a right old carry on.

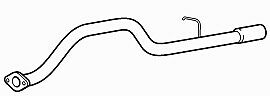

Plan B at time of writing is to buy in some universal 1.75" bore 45 degree elbows and clamps. These will give me much more flexibility as I can slot them together until I’m happy with the fit, then clamp them up with some exhaust paste, cutting and welding will need to be right first time really. The sections have a centre line radius of 100mm, if I cut the current exhaust just where it starts to bend back down, slide the 45 degree elbow on (pushing the bend point back by approx 80mm) then fit a second 45 degree elbow to line the pipe back up with the rearmost section - which I can shorten as required - and it should all be OK. The elbows have one flared & slotted end and one regular end, so they should slip together for the purposes of getting it all aligned, then I can just clamp it up and it should be fine.

I’ll look at sourcing the bits from ebay, it looks like it should come in under £30 for two elbows, clamps and assembly paste which is hardly a huge cost to swallow.

The manicat from @Rallynrace arrived too, so thats something for probably next month after I get paid, I can offload that onto a garage to do the manifold and rear beam bushes in one hit.