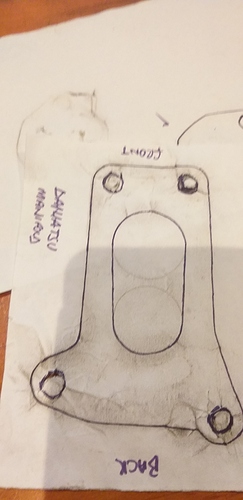

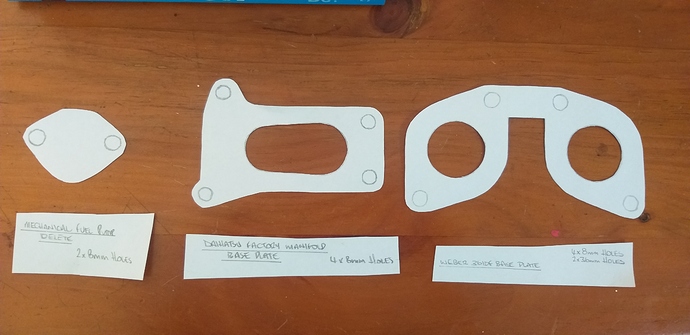

The Daihatsu manifold is actually 2 hole but I’ll dremel it out to one large oval shape.

Looks good, following with interest…

Any idea of the choke size? That’ll be the first step for getting it tuned.

Also what was it off previously capacity wise? Jetting may already be close. When I did mine they were brand new with the largest chokes fitted and generic jetting. It was a bit of a crap shoot getting the baselines to work from hence I have a few jets left over and maybe able to help out once its going.

Chokes - 32

Main Jets - 145

Emulsion Tube - F57

Idle Jets- 47

Starter Jets - F7 80

Auxiliary Venturi - 45

Air Correctors - 235

I got it off a guy that races Formula Vee with the VW engines. Saw it on a shelf in his shop, he said it was a matching pair on a bug but the other one was destroyed in a crash. Didn’t actually ask the size of the VW engine but if it was on a 1200cc then it should have good sizes for my 660cc.

No extra cash for playing with cars at the moment so best I could do was cutout the Webber templates and source some 10mm steel plate.

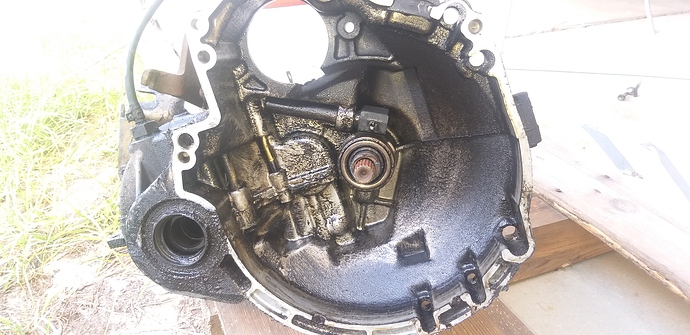

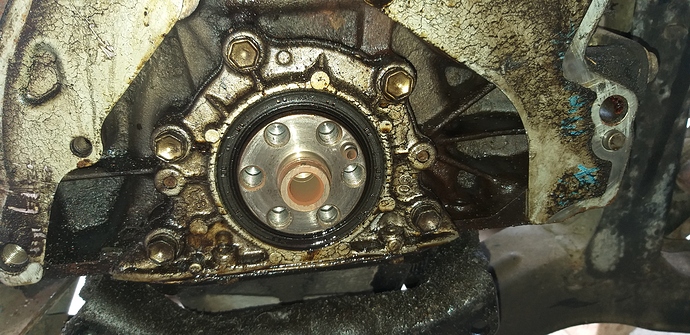

So this week I’m off work so I’ve decided to fix my leaking four speed manual.

I’m not sure what model this gearbox came out of, the original gearbox was the normal five speed but the last owner purchased the car just to take the five speed and replaced it with this four speed.

So far I’ve got the gearbox out after dropping the subframe. The gearbox has been opened before based on the amount of grey silicone between the case joints.

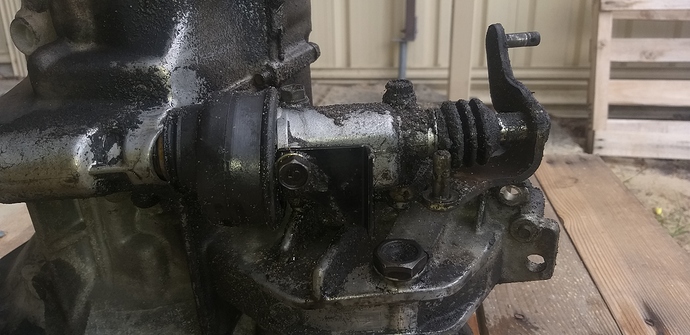

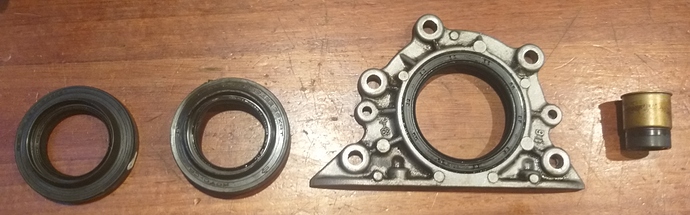

It’s leaking from the axle seals and perhaps the shifter shaft seal, it’s just hard to tell with the amount of oil covering the underside of the gearbox. I’ve also discovered the rear main seal is leaking too, but the metal plate that the rms sits in could be leaking too.

Now I’ve never done anything with manual gearboxes before except for change clutches. I can buy and change the axle shaft seals and the rear main seal easily enough. The rms plate I can remove, clean and refit using the correct silicone.

What stumps me is the selector shaft seal. Is it leaking? If I don’t replace it and fit the box then it leaks then it has to come all out again. My problem is I’ve heard from a couple of people that the gearbox needs to come apart to get to this seal as it’s fitted inside to out. I’ve found no documents of this gearbox to assist me but nearly all YouTube videos and website show other fwd gearboxes having their selector shaft seals changed from the outside. If that’s the case then fantastic and easy as I’m afraid if I open the box I’ll muck it up with bits falling out.

Box is fairly easy to split. Once apart they are quite logical. I would open it up as my experience is that the drive shaft seals are best installed while apart. That way you can use a really slim amount Threebond sealant around the seal and seat each in place on a gearbox half and then close the other half over thet top. Just flicking them out and pushing new seals can push sealant everywhere. Also you get to check or replace the input shaft seal when all is apart. I have an efel box opened up on the bench at work (I’m home now) and will endeavour to send a picture so you know what is inside.

@Mr_Gormsby thanks for your help and advise.

I had a quick test of my L80 four speed. It all lines up and almost fits but the selector shaft fouls on the subframe.

That was worth opening up. Looks like huge thrust load on it.

Big rubber mallet hitting in shear whole lifting the two halves apart

Oh, engine oil, gearbox oil, coolant, degreaser and good quality silicone.

I use Threebond 1207C as it is especially for gearboxes. Put a bead around the driveshaft seals as well as the smallest bead around the houseing, and the input shaft OD too.

Thank you for the heads up

Is selector shaft seal the correct name for that part,? I’m really struggling to find that part especially when there’s no part number on it.

Measure the od, width and shaft diameter. I think it is a generic seal and not proprietary Daihatsu. We have a hose and seal shop here I take that sort of thing to