I used to work with such colors, as I was upcycling bicycles and mopeds.

Here’s one ugly duckling that needed just some white contast and chrome. Are you planning to colour your interior? White vinyl paint should still be available.

Almost unbelievable that it’s the same bicycle?

Door panel pleating with brushed aluminium trim would also look inviting? I once had one of these in white, before it got stolen in Detroit:

1 Like

I’m thinking of skinning the doors with 1mm aluminium sheet that’s been powder coated or 1.5mm acrylic plastic sheets that are vinyl wrapped.

2 Likes

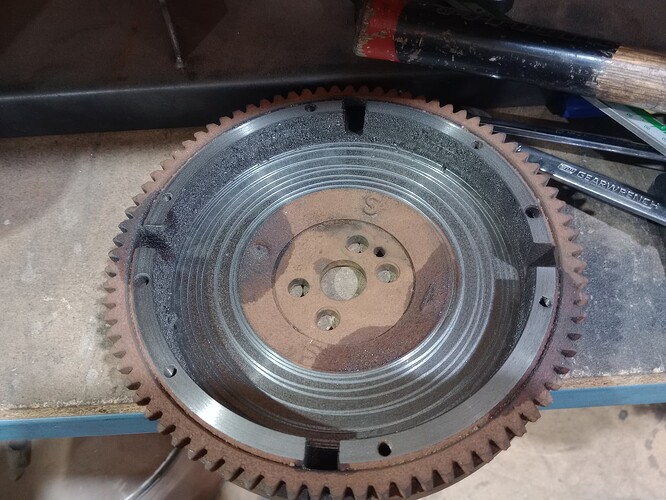

I’ve started machining my flywheel on the work lathe.

I got a really nice cut on it, and have experimented with some aggressive cuts to help the clutch bed in quicker.

I’ll take photos tomorrow

2 Likes

It’s an experiment as to whether it will work. I can’t see why not.

4 Likes

Just do a static balance on it. It is what I did on the cb flywheel Mr G did for me and it was sweet.

4 bolts, well I’ll be! I didn’t know that. If you do another one anytime, see if you can take a little off the ring gear below the teeth. I often put a groove with a fairly large radius tool going 5-7mm deep and as wide as possible going within 2mm of the starter gears and on inner 2mm from the casting.

I’m not sure what you mean but if I understand correctly. The ring gear is flush with the raised section of the flywheel. I’ve only removed enough material for the pressure plate to clear.

I found this when I was fixing the rear number plate and tow strap mount on the car.

Needless to say it’s straight on the supercharged engine.

2 Likes

[quote=“DaleJeffree, post:243, topic:197”]…The things I changed was the length of the slot in the adjustment slot…[/quote]Another possibility would have been to enlarge the tensioner’s diameter, through pressing it into a tube cut down to the tensioner’s width?

I bolted things together to gain some motivation, but now I’m thinking of building my clutch again, the 6 fasteners that hold the pressure plate ring in place aren’t making me happy. I either need to make small standoffs to hold the ring in place or tap the mounting plate for a m8 thread and use m8 bolts and cone nuts to lock the ring in place.

2 Likes

I’ve hit a snag. With a standard flywheel the custom clutch doesn’t clear the throw out bearing, 4mm discrepancy. The option appear to be

**

Make a 5 mm spacer for the gear, remove 5mm from the starter motor mounting flange on the gearbox.

**

Remove the excess material from the flywheel only, being careful to to remove material supporting the ring gear

**

Pay for an updated pressure plate.

**

Fit a standard clutch and pray I am wrong about it potentially making 100-120hp.

1 Like

easy way out is the last one but if you are right it will be out it comes again. Not sure if you want to do that after it’s in?

I fixed it with an unspecified 5th option. Not enough preload on the pressure plate. I forgot these clutches are nearly flat when bolted into the flywheel, plus my bolts and cone lock nuts were loose enough to rotate.

I’d remove some from the flywheel if the bolts still have enough engagement. For the effort the flywheel loses mass. Take radius cut into the ring gear while you are at it.

Weighed the set up, should be near on 10 or 11 kg when fitted.

4 Likes

I’m trying to stay motivated on all of this but with funds having very much dried up and progress becoming a back burner now that I’m working and also managing my own ceramic coating business.

There really isn’t much to get it going other than motivation and time. I rediscovered gaming on PC (MacBook in this case), and the new Forza Motorsport is ok.

1 Like

The last progress picture.

1 Like

is this turbo and not S/C?

1 Like

No it’s supercharged, the Tial gate is being used as a pop valve on the inlet manifold. I have 1.5 bar (21 psi) of spring pressure at the moment. The plan is to direct the backfire past the alternator and towards the ground, so my internal combustion engine doesn’t temporarily become an external combustion engine.

4 Likes

And here is a side project that I started working on.

I do love a side project. If it’s a small job it’s easier to get excited about.

2 Likes