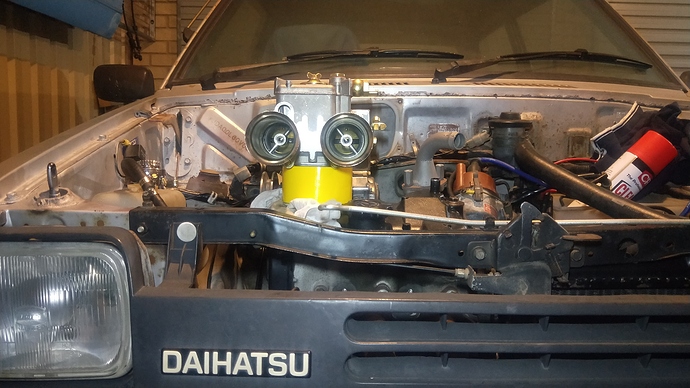

looks like some sort of small robot looking at me lol

Well this is a different take on on a handivan

Nice to see the work you have done, it’s fun in the stock engine bay.

Should look at the golf cart rims and tyres on ebay. 10" x 7" with a 205/50 series tyre, or 12" x 8" with a 235/45 on them.

I used 10" on my first one, had more traction around corners than you could handle, ended up in the passenger side a few times  the 12"'s would be be better. And the loading on them is plenty for the handivan. 660 pounds load per tyre off memory

the 12"'s would be be better. And the loading on them is plenty for the handivan. 660 pounds load per tyre off memory

BTW, you wouldn’t have a spare windscreen around?? I’m having a hell of a time getting one for my handivan, about to give up and get some lexan

I will be upgrading to 15 inch wheels to fit Compact Motorsport brake upgrade when money permits. I have been working on a 4x100 hub upgrade from a Cuore hub and HiJet strut combo

I’m really interested in how these go. I’m looking at a L251 for my next Dai and hoping to do this upgrade too.

Ahh, yes. 195/45/15"s are available and are 550mm diameter, close to a stock 12".

Running them on the front on mine to get as much clearance as possible

Most likely using Copen mags with 165/40r15

That’s cool, even smaller diameter again

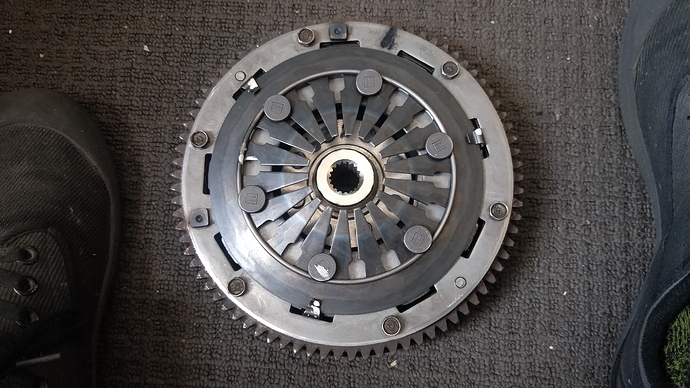

So ever driven a car with a brass plate clutch before ?

Turns the clutch into a switch, on or off with very little in-between

Not yet, the car won’t be a daily.

Just reading through this thread I feel like I’ve learnt a huge amount. Keep us updated, not only is this awesome it’s teaching me a lot haha. Thanks for posting this!

Thanks, I felt like this is the collective ramblings of a old man and his never ending project

Well progress is very slow, and as always it come down to money and the issue of not having any for cars right now.

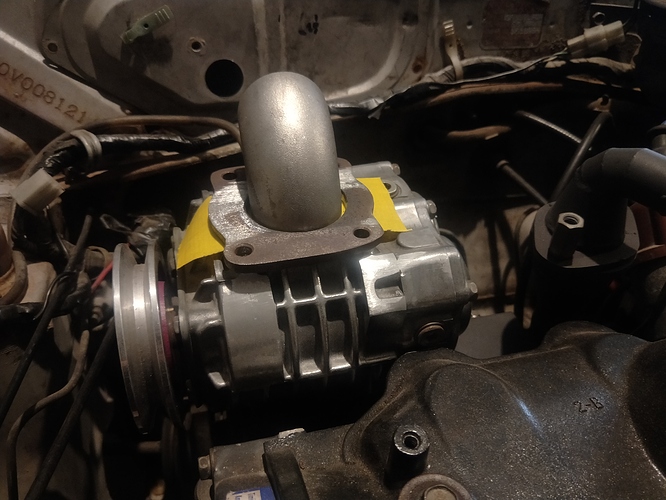

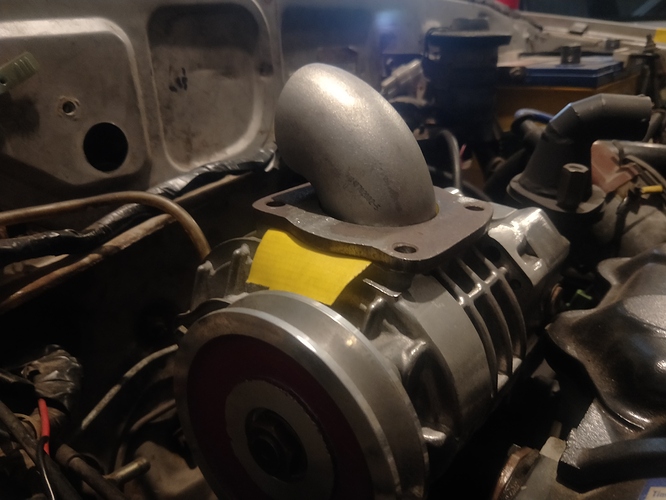

Yes this is another carby to blower inlet, the aim is to not chop the bonnet.

Hopefully some more cash flows my way and this will continue once again.

good idea not to chop the bonnet. not like they make them anymore

Tonight I spent a tad over 30 minutes chopping thick wall stainless steel steam pipe. That was fun.

Tomorrow I will shape the join I have to make, unfortunately it won’t be pretty but it will function.

Having chopped this back and made an angle I had to, to make the turn. This will get a severe tickling inside for a nicer radius.

This is a big bugger of a hand tool, although it can be handled with one, i recommend two hands. Has handles most of the job with making every radius smoother.

I am enjoying this fabrication Dale. Nice work mate